Preparation method for decorative plate

A technology for decorative sheets and substrates, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of texture and pattern deviation, unable to meet the user's pursuit of natural beauty, and unable to be processed, etc. smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

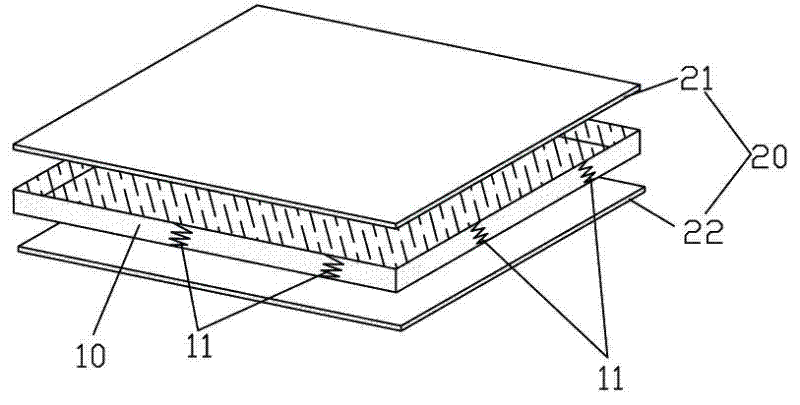

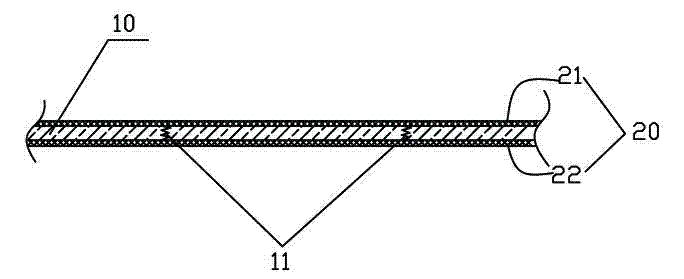

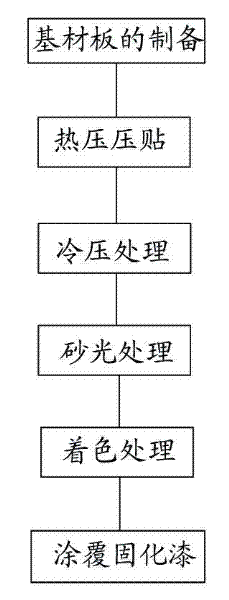

[0030] Such as Figure 1-3 As shown, Embodiment 1 of the present invention provides a method for preparing a decorative board, and the prepared decorative board includes a substrate board 10, a veneer layer 20 and a coating layer (not shown in the figure), and the base board 10 is Timber residues or small-sized natural wood strips are processed by a splicing machine. The veneer layer 20 is melamine-impregnated paper that is hot-pressed and pressed on the surface of the base plate at the same time. The coating layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com