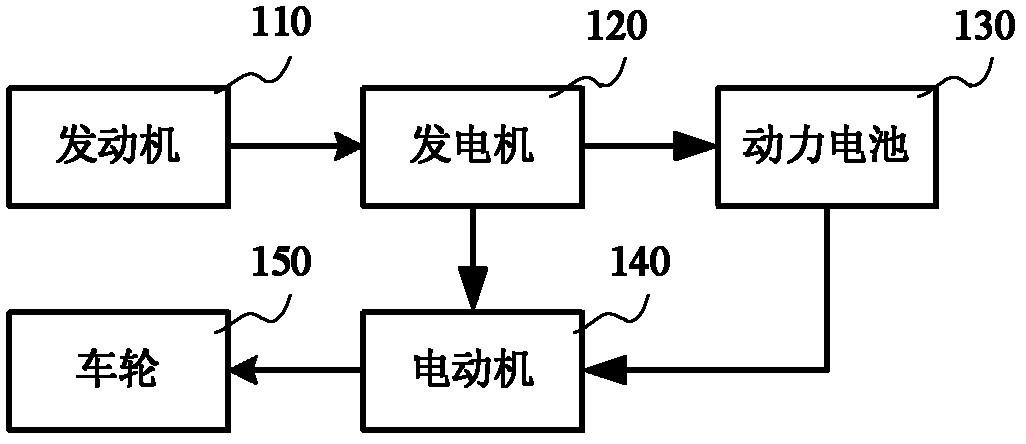

Power battery system and control method

A technology of a power battery and a control method, which is applied in the field of vehicles, can solve the problems of shortening the life of the power battery 130, and achieve the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

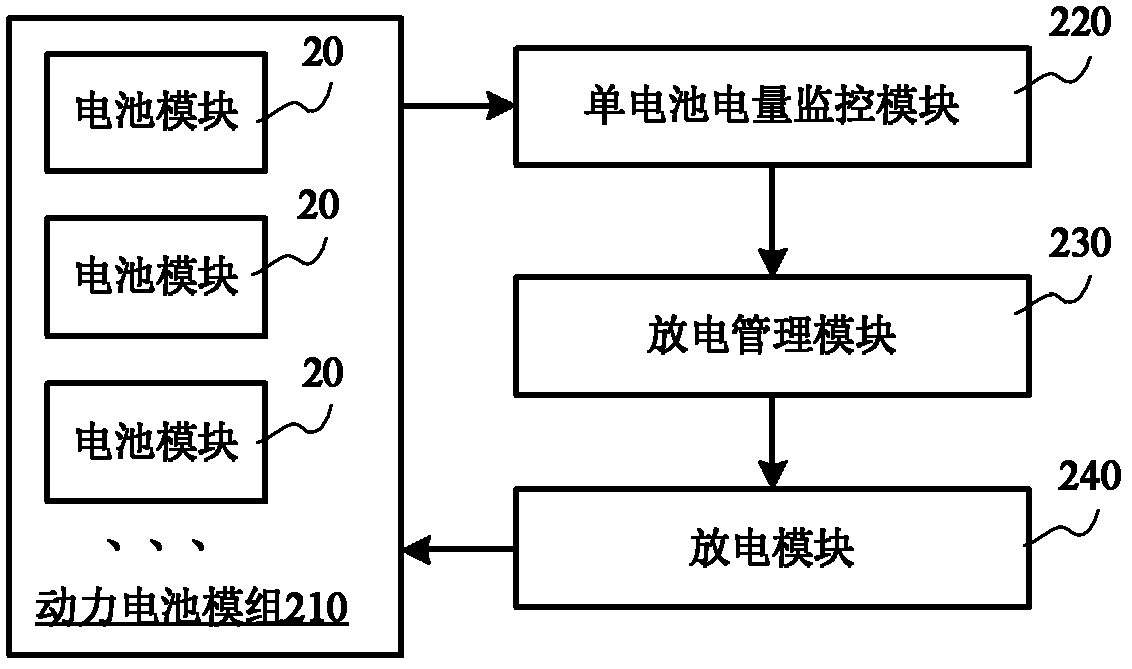

[0045] Please refer to figure 2 , which shows a structural block diagram of the power battery system provided by Embodiment 1 of the present invention. The power battery system can be used for extended-range electric vehicles, and the power battery system includes a power battery module 210 , a battery power monitoring module 220 , a discharge management module 230 and a discharge module 240 .

[0046] The power battery module 210 includes several battery modules 20 . The several battery modules may be at least two battery modules. The several battery modules 20 can also be the same battery modules, that is, the several battery modules 20 can all have the same output voltage, output current, charging voltage, charging current, total voltage, battery capacity and other parameters. Battery pack. The output voltage of each battery module 20 can be the working voltage required by the motor.

[0047] The battery power monitoring module 220 is used to monitor the power state of...

Embodiment 2

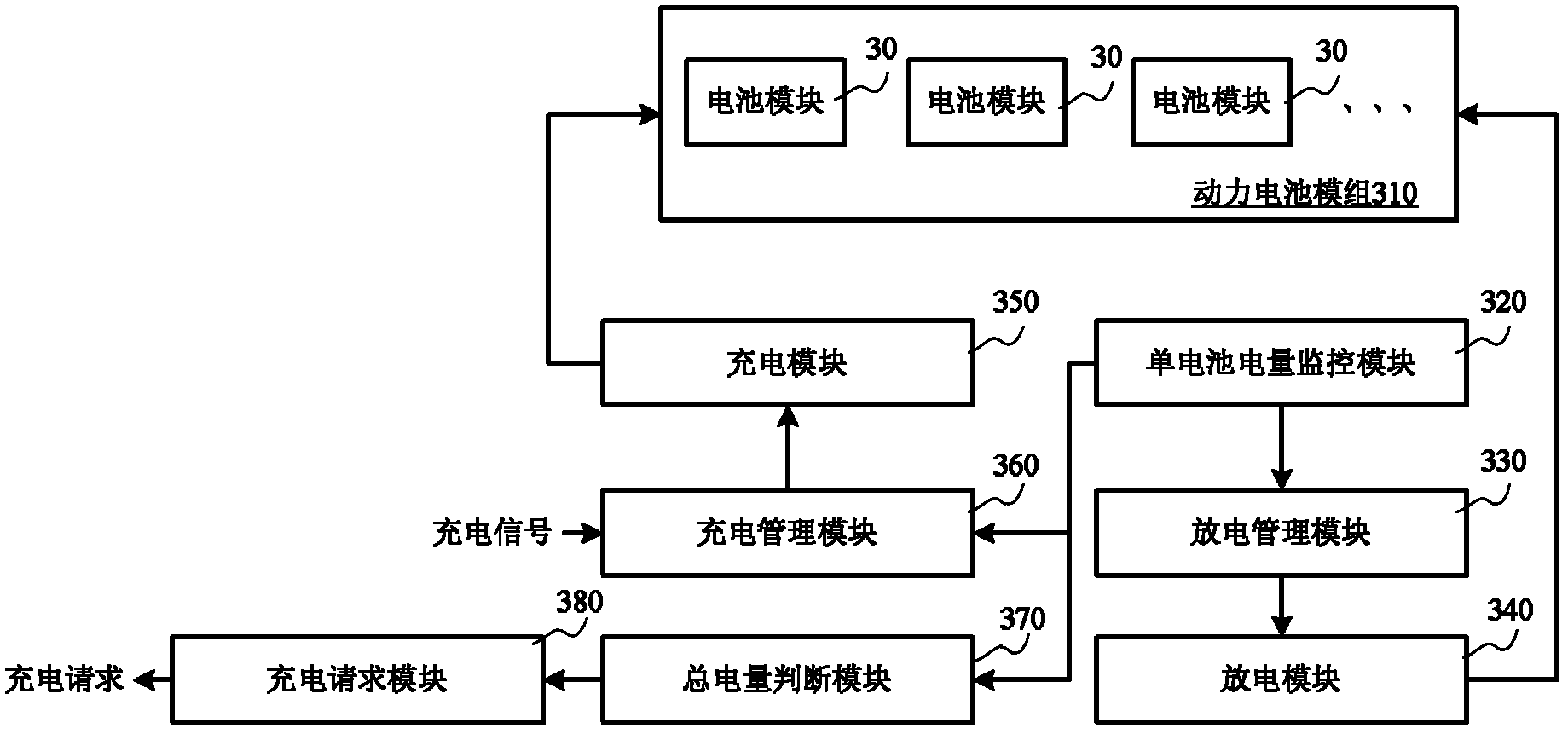

[0052] Please refer to image 3 , which shows a structural block diagram of the power battery system provided by Embodiment 1 of the present invention. The power battery system can be used for extended-range electric vehicles. The power battery system includes a power battery module 310, a single battery power monitoring module 320, a discharge management module 330, a discharge module 340, a charge management module 350, a charge module 360, and The battery capacity judgment module 370 and the charging request module 380 .

[0053] The power battery module 310 includes several battery modules 30 . The several battery modules may be at least two battery modules. The several battery modules 30 can also be the same battery modules, that is, the several battery modules 30 can all have the same output voltage, output current, charging voltage, charging current, total voltage, battery capacity and other parameters. Battery pack. The output voltage of each battery module 30 can ...

Embodiment 3

[0063] Please refer to Figure 4 , which shows a method flowchart of the control method provided by Embodiment 3 of the present invention. The control method can be used in a power battery system including multiple battery modules, and the control method includes:

[0064] Step 401, monitoring the power state of each battery module, the power state includes a fully charged state, a partially charged state and an empty state;

[0065] Step 402, put the battery module whose power state changes from a non-full charge state to a full charge state into a sequence to be discharged;

[0066] Step 403, when the discharge signal is received, the battery modules in the sequence to be discharged are discharged sequentially.

[0067] Specifically, discharging the battery modules in the sequence to be discharged sequentially includes: after the power state of the battery module currently being discharged changes from a non-full state to an empty state, stopping the discharge of the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com