Method for catalytic synthesis of tributyl citrate by utilizing immobilized p-toluenesulfonic acid

A technology of tributyl citrate and p-toluenesulfonic acid, which is applied in the chemical industry, can solve the problems of complex post-treatment process, many catalyst side reactions, complex preparation process, etc., achieve easy recovery and reuse, and improve the efficiency of esterification reaction , The effect of simplifying the post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of immobilized p-toluenesulfonic acid

[0023] Add 2.5g of sodium alginate, 5g of polyvinyl alcohol and 1.5g of p-toluenesulfonic acid into 100mL of deionized water, mix well, heat in a constant temperature water bath at 80°C to dissolve completely, cool to about 45°C, and use a constant temperature The flow pump drips it into 100mL of calcium chloride solution with a mass percentage of 1.5% at a speed of 60rpm and continuously stirs at a slow speed. After the calcium chloride solution is dripped, stop stirring, and place it at 4°C for crosslinking for 24 hours. After that, it was taken out and filtered to obtain immobilized p-toluenesulfonic acid.

[0024] 2) Esterification reaction

[0025] Add 308g of n-butanol, 200g of citric acid, and the immobilized p-toluenesulfonic acid obtained in step 1) into a 500mL three-neck flask equipped with electromagnetic stirring, a thermometer, a reflux condenser, and a water separator, and heat and reflux at 130°C. ...

Embodiment 2-4

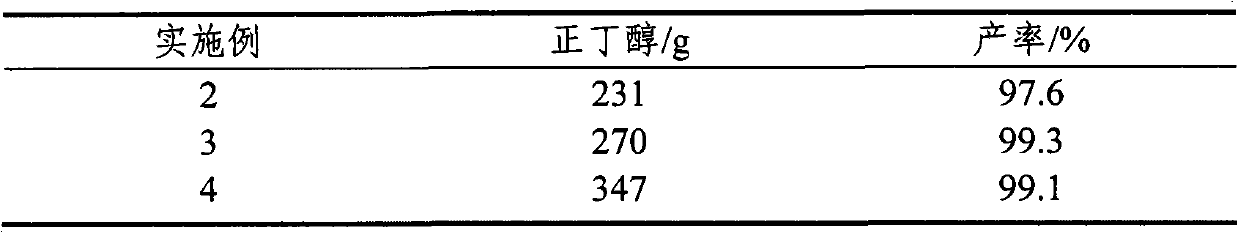

[0029] Only change n-butanol consumption, all the other are with embodiment 1. The results are shown in Table 1.

[0030] Table 1

[0031]

Embodiment 5-7

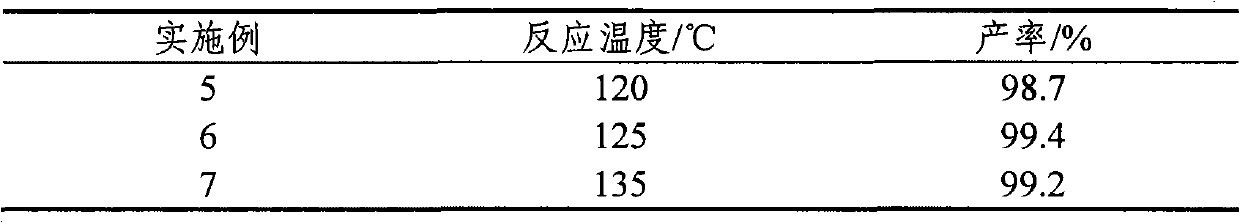

[0033] Only change the esterification reaction temperature, all the other are with embodiment 1. The results are shown in Table 2.

[0034] Table 2

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com