A device and method for electrochemical hydrogen permeation measurement in high temperature environment

A high-temperature environment, electrochemical technology, used in measurement devices, material electrochemical variables, scientific instruments, etc., can solve the problems of inability to meet measurement requirements, low temperature, etc., and achieve stable measurement results, low cost, and good conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

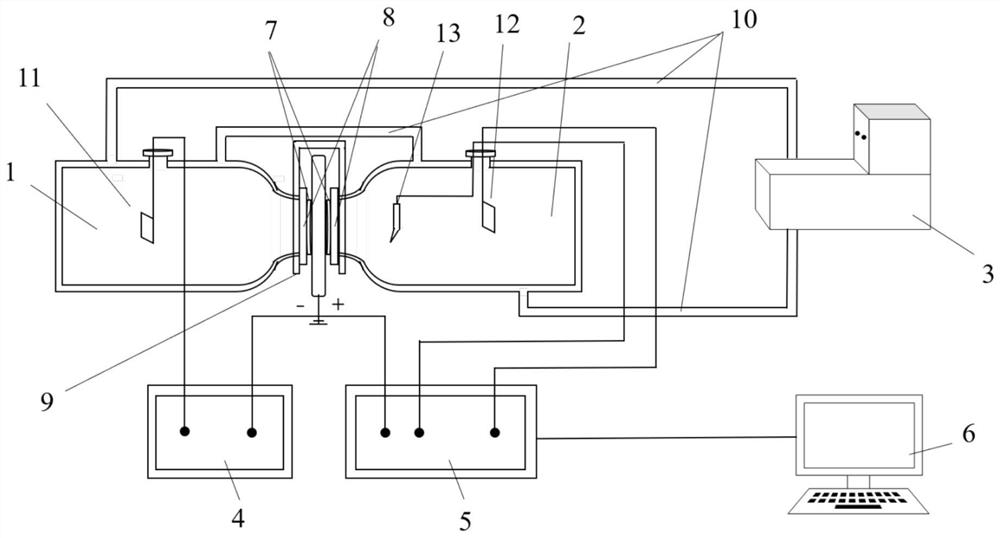

[0032] A device for electrochemical hydrogen permeation measurement in a high temperature environment, comprising a cathode chamber 1, an anode chamber 2, an external circulating constant temperature oil bath device 3, a constant current meter 4, an electrochemical workstation 5 and a data acquisition device 6;

[0033] The opposite sides of the cathode chamber 1 and the anode chamber 2 are all open, and the sealing gasket 7 is glued around the opening, and the opening sides of the cathode chamber 1 and the anode chamber 2 all have flanges 8, and the cathode chamber 1 and the anode chamber 2. The flange 9 clamps the flange 8 so that the sealing gasket 7 fits tightly; the cathode chamber 1 and the anode chamber 2 are filled with an electrolyte, and the electrolyte is organic Alcohol is the matrix, and phosphoric acid and phosphate are dissolved in the matrix; the external circulating constant temperature oil bath device 3 is connected to the interlayer of the cathode chamber 1 a...

Embodiment 2

[0036] A device for electrochemical hydrogen permeation measurement in a high temperature environment, comprising a cathode chamber 1, an anode chamber 2, an external circulating constant temperature oil bath device 3, a constant current meter 4, an electrochemical workstation 5 and a data acquisition device 6;

[0037] The opposite sides of the cathode chamber 1 and the anode chamber 2 are all open, and the sealing gasket 7 is glued around the opening, and the opening sides of the cathode chamber 1 and the anode chamber 2 all have flanges 8, and the cathode chamber 1 and the anode chamber 2. The flange 9 clamps the flange 8 so that the sealing gasket 7 fits tightly; the cathode chamber 1 and the anode chamber 2 are filled with an electrolyte, and the electrolyte is organic Alcohol is the matrix, and phosphoric acid and phosphate are dissolved in the matrix; the external circulating constant temperature oil bath device 3 is connected to the interlayer of the cathode chamber 1 a...

Embodiment 3

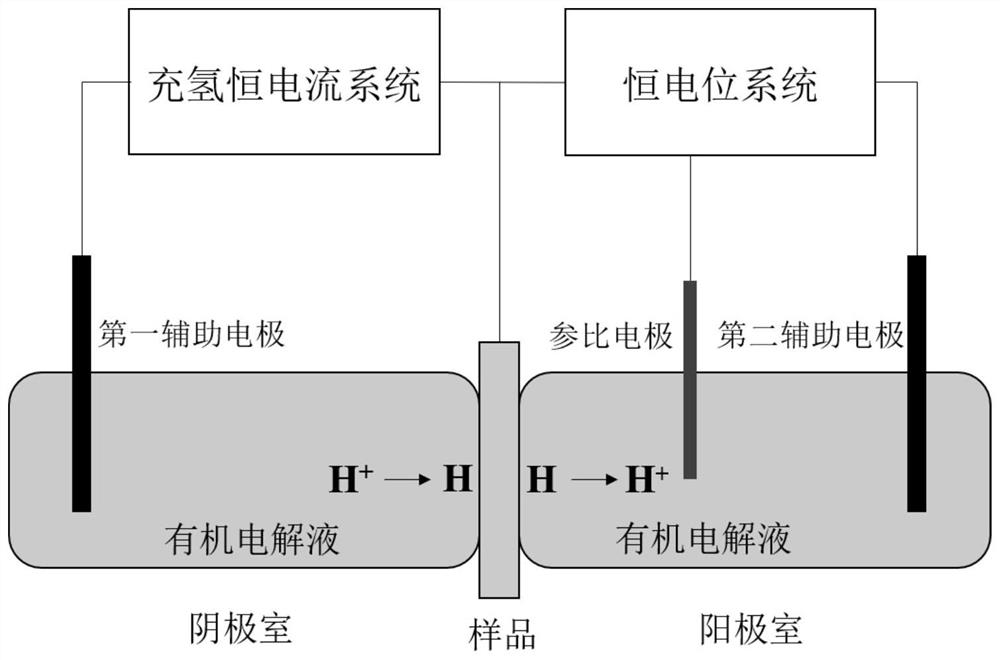

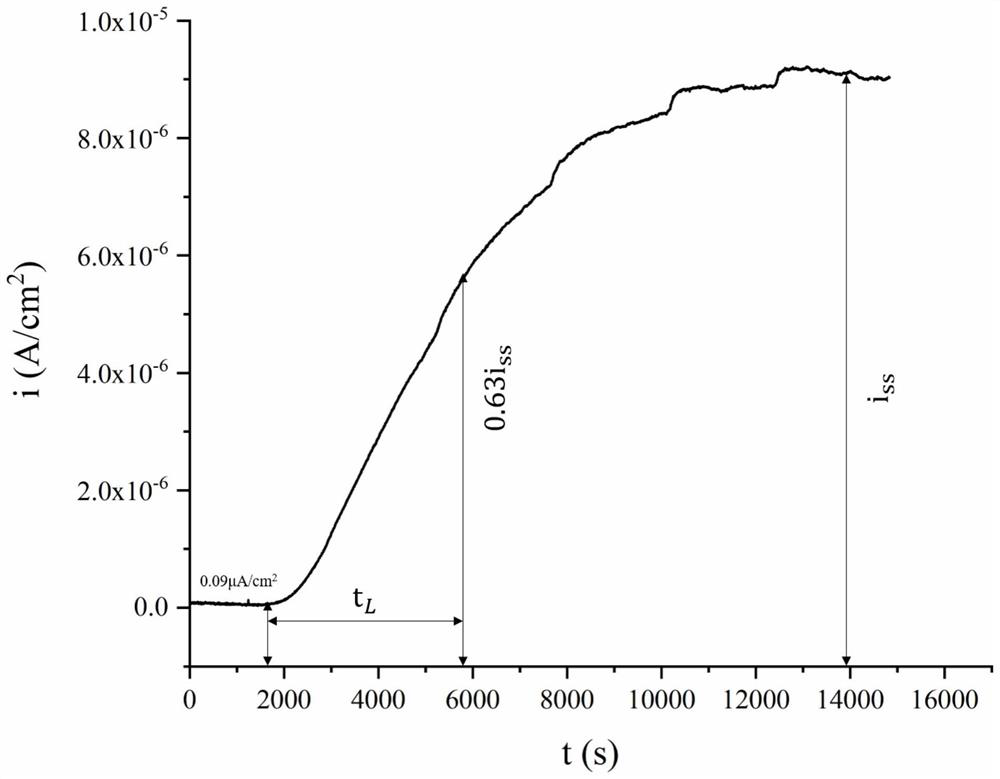

[0043] This embodiment adopts 0.2mol / L NaH 2 PO 4 +0.1mol / L H 3 PO 4 Glycerol organic electrolyte, for N-ODS steel (composition is Fe-9.96Cr-2.82W-1.42Mn-0.25V-0.11C+0.3%Ti+0.35%Y 2 o 3 +0.1N(wt%)), to measure the hydrogen permeation performance in a high temperature environment of 80°C, the specific steps include:

[0044] Step 1: Process the N-ODS steel sample to be tested into a circular sheet sample with a diameter of 30mm larger than the sealing gasket 7 of the test device and 20mm in diameter; sandpaper 400, 800, 1000, 1200, 1500, 2000 on both sides of the sample Grinding and polishing, then ultrasonic cleaning with acetone, alcohol cleaning and drying, the measured sample thickness is 0.96mm;

[0045] Step 2: Seal the N-ODS steel sample to be tested between the cathode chamber 1 and the anode chamber 2 through the sealing gasket 7 and the flange 9, and simultaneously place the N-ODS steel, the first auxiliary electrode 11, the second auxiliary electrode 12, The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com