A hydroxyapatite ultra-long nanowire-based high temperature resistant battery separator and its application

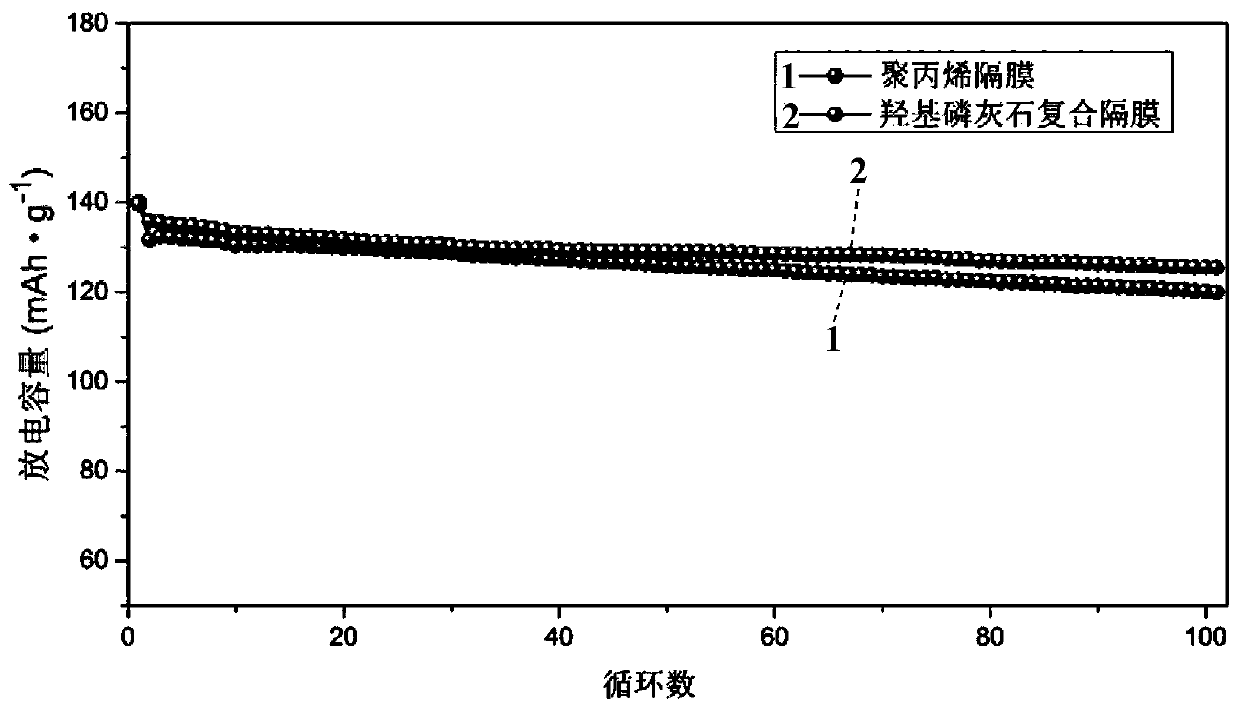

A hydroxyapatite, battery separator technology, applied in nanotechnology, nanotechnology, battery pack components and other directions, can solve the problems of poor electrolyte wettability, low thermal temperature stability, low porosity, etc., to achieve good wettability, Good flame retardant performance and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The ultra-long hydroxyapatite nanowires of the present invention can be prepared by solvothermal method, hydrothermal method or any suitable method, which can be prepared by referring to published patents and literature reports, such as: Zhu Yingjie, Lu Bingqiang , Feng Chen, High-flexibility, high-temperature, non-combustible hydroxyapatite paper and its preparation method, Patent No. ZL201310687363.2; Yong-Gang Zhang, Ying-Jie Zhu Feng Chen, Jin Wu, Materials Letters, 144, 135-137 (2015 ); Ying-YingJiang,Ying-Jie Zhu,Feng Chen,Jin Wu,Ceramics International,41,6098-6102(2015);Heng Li,Ying-Jie Zhu,Ying-Ying Jiang,Ya-Dong Yu,Feng Chen, Li-YingDong, Jin Wu, ChemNanoMat, 3, 259-268 (2017). The solvothermal method includes: (1) mixing a fatty acid and an alcohol, adding a water-soluble calcium salt aqueous solution and a strong alkali aqueous solution under stirring to form a fatty acid calcium precursor, the fatty acid being a medium-chain or long-chain fatty acid, preferab...

Embodiment 1

[0036] At room temperature, take 10g of hydroxyapatite ultra-long nanowire slurry with a concentration of 3mg / g and disperse it in 40mL of deionized water, add 0.6g of an aqueous suspension of plant fiber with a concentration of 5‰, and stir for 30 minutes. It is placed on a sand core funnel with a diameter of 45 mm for suction filtration. After separation and drying, a piece of hydroxyapatite ultra-long nanowire-based high-temperature battery diaphragm with a diameter of 45 mm and a thickness of about 49 microns is obtained.

Embodiment 2

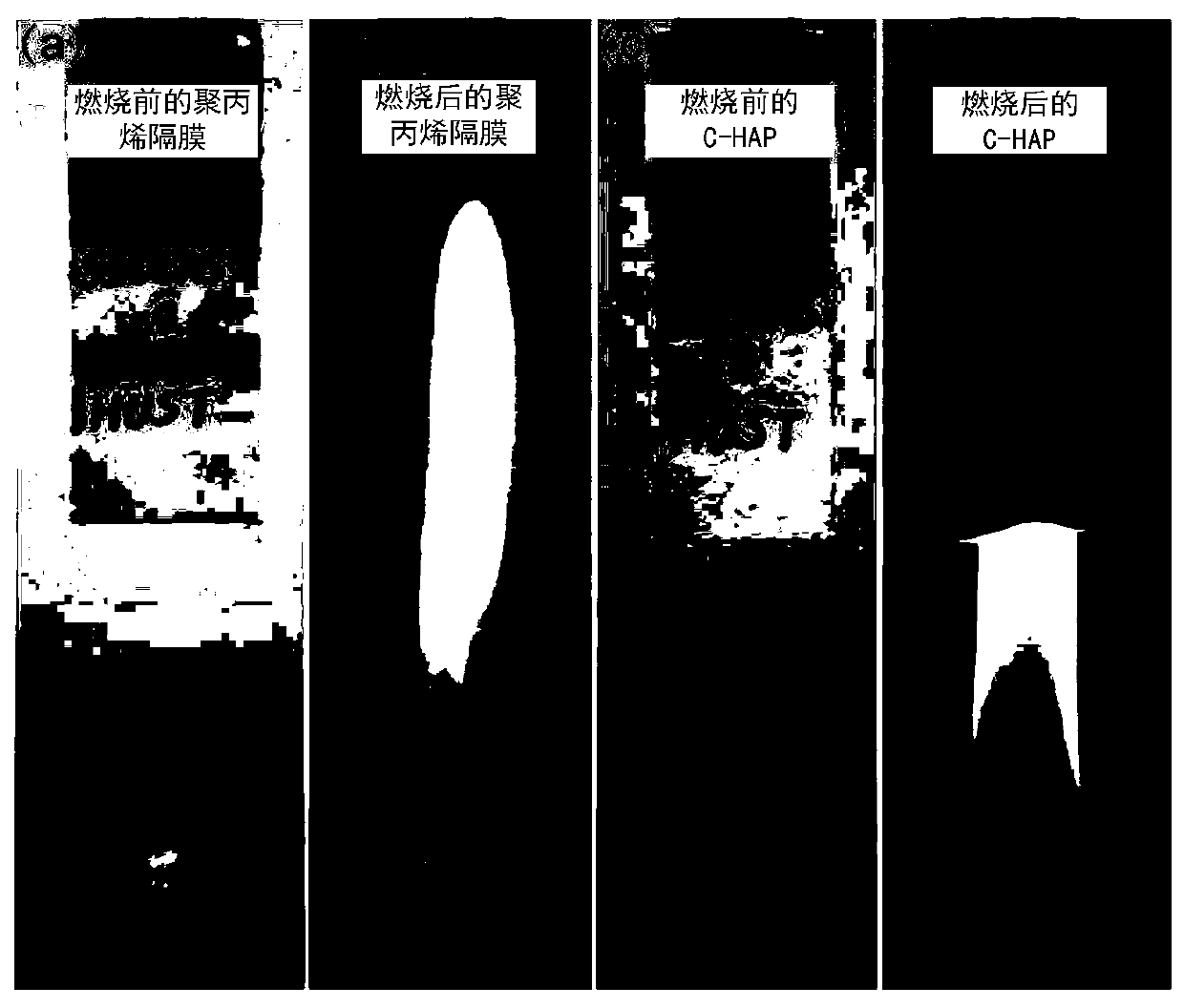

[0038] At room temperature, disperse 200g of 3mg / g hydroxyapatite ultra-long nanowire slurry in 1200mL of deionized water, stir evenly, then add 18g of 5‰ plant fiber aqueous suspension and continue to stir for 30 minutes. It is placed on a 20 cm diameter slide filter and separated, and after drying, a hydroxyapatite ultra-long nanowire-based composite battery separator with a diameter of 20 cm and a thickness of about 60 microns is obtained. figure 1 In (c) and (d) are the digital photos of the hydroxyapatite ultra-long nanowire-based composite battery diaphragm prepared in this example before and after burning on the flame of an alcohol lamp. It can be seen that the hydroxyapatite ultra-long nanowire-based The high temperature battery separator has excellent high temperature resistance and flame retardant properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com