Electric vehicle battery temperature control system

An electric vehicle and battery temperature control technology, applied in the field of auto parts related systems, can solve the problems of battery life, capacity and safety reduction, and achieve the effect of ensuring normal use and safety, ensuring capacity and safety, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

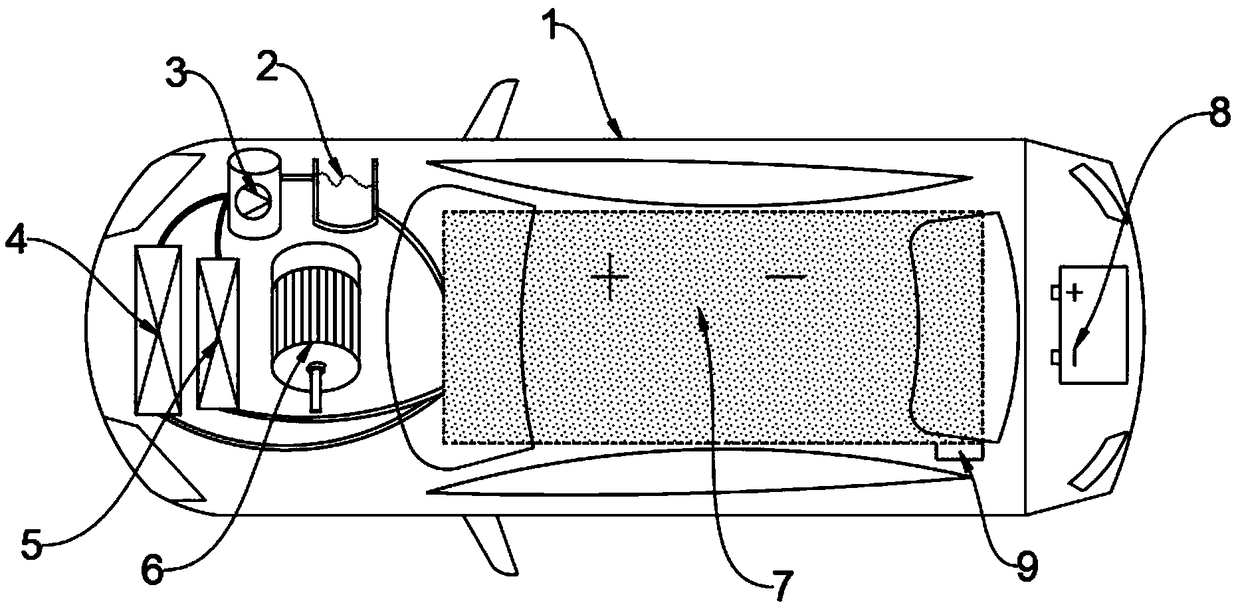

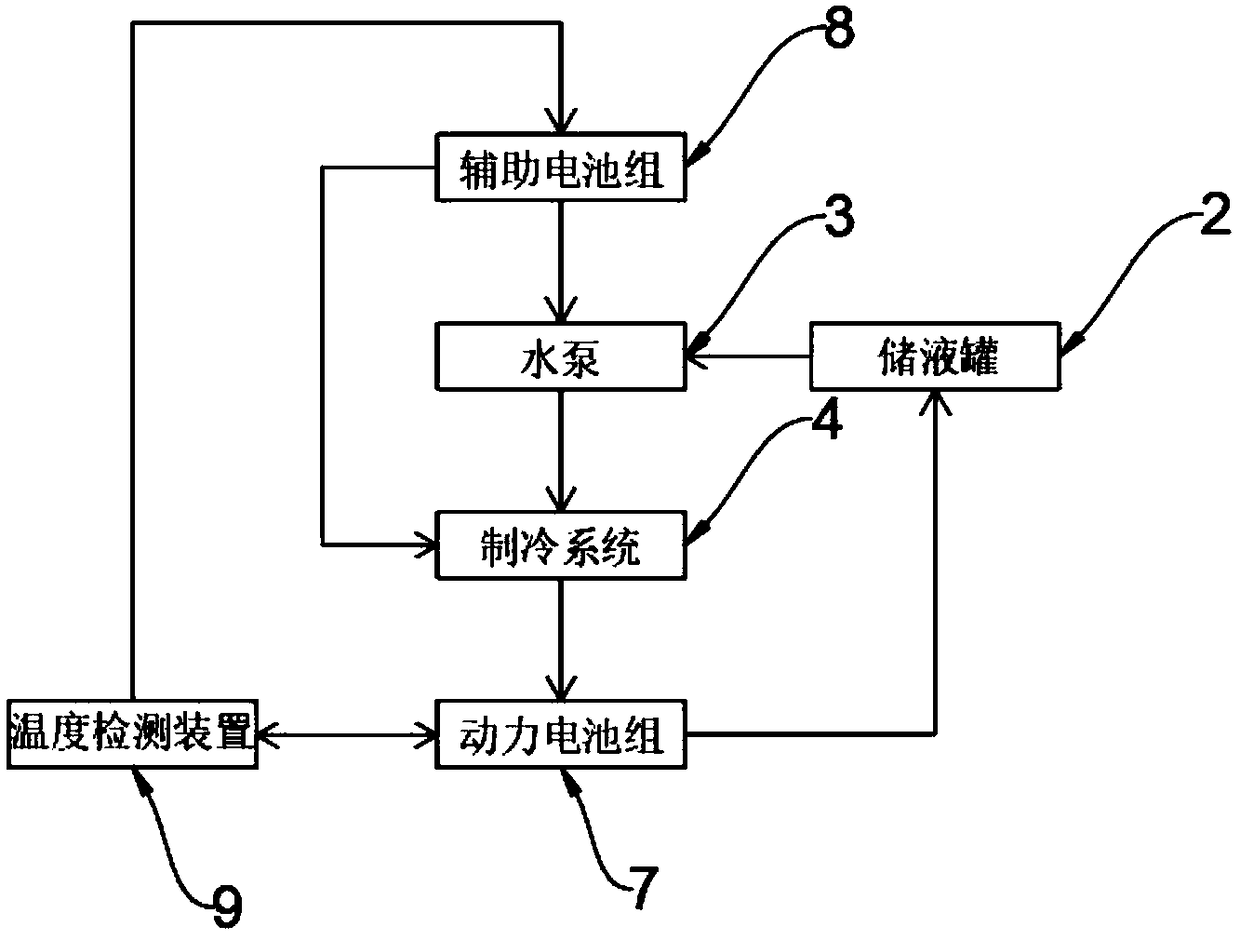

[0033] see figure 1 , figure 2 , an embodiment provided by the present invention: an electric vehicle battery temperature control system, including an electric vehicle 1, an auxiliary battery pack 8 is installed on one side of the electric vehicle 1, and a power battery is installed on the other side of the auxiliary battery pack 8 Group 7, a temperature detection device 9 is installed on one side of the lower end of the power battery pack 7, a motor 6 is installed on the other side of the power battery pack 7, a liquid storage tank 2 is installed on the upper end of the motor 6, and the other side of the liquid storage tank 2 A water pump 3 is installed, and the water pump 3 pumps out the antifreeze coolant from the liquid storage tank 2, and a heating system 5 is installed on the other side of the motor 6, and the heating system 5 is heated in advance to restore the working temperature range of the power battery pack 7 Normal value, the refrigeration system 4 is installed ...

Embodiment 2

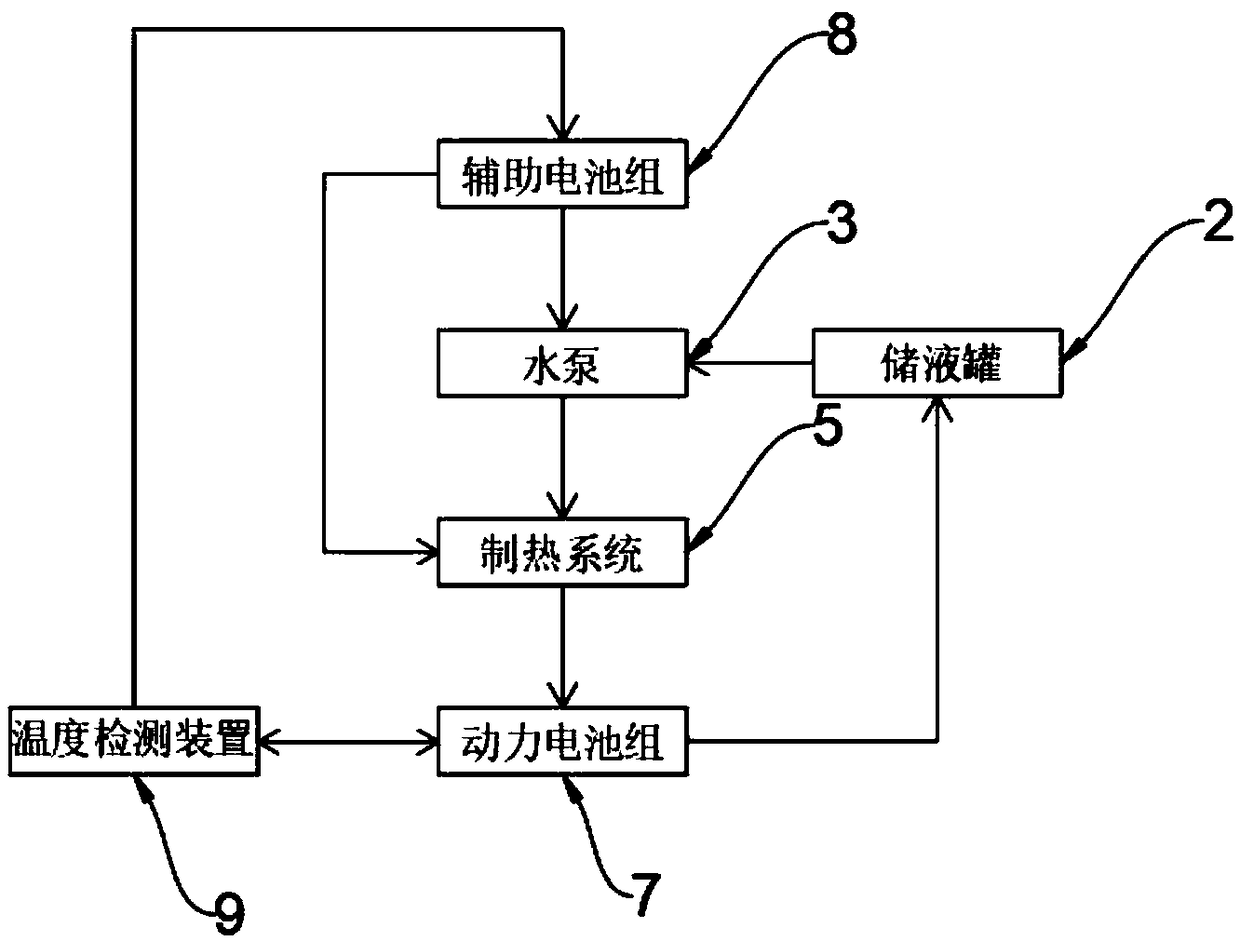

[0048] see figure 1 , image 3 , another embodiment provided by the present invention: an electric vehicle battery temperature control system, including an electric vehicle 1, an auxiliary battery pack 8 is installed on one side of the electric vehicle 1, and a power supply is installed on the other side of the auxiliary battery pack 8. A battery pack 7, a temperature detection device 9 is installed on one side of the lower end of the power battery pack 7, a motor 6 is installed on the other side of the power battery pack 7, a liquid storage tank 2 is installed on the upper end of the motor 6, and the other side of the liquid storage tank 2 A water pump 3 is installed on one side, and the water pump 3 pumps out the antifreeze coolant from the liquid storage tank 2. A heating system 5 is installed on the other side of the motor 6. The heating system 5 is heated in advance to make the working temperature range of the power battery pack 7 To return to the normal value, a refrige...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com