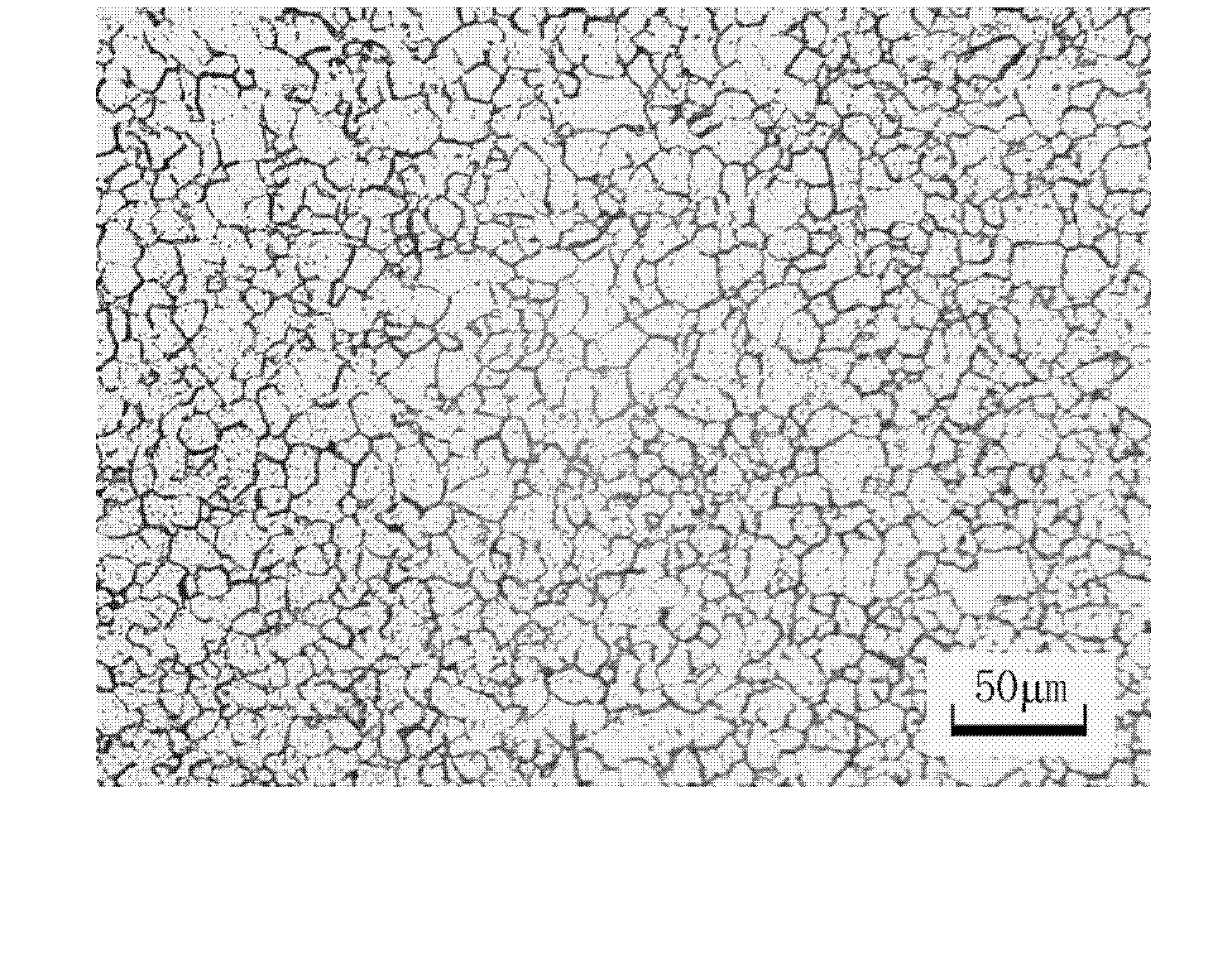

Seawater corrosion resistant structural steel with uniform metallographic structure and production method thereof

A metallographic structure and seawater-resistant technology, applied in the field of steel materials, can solve the problems of short service life, poor uniformity, low marine corrosion resistance, etc., achieve good strength, meet market demand, thermal deformation and excellent welding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below:

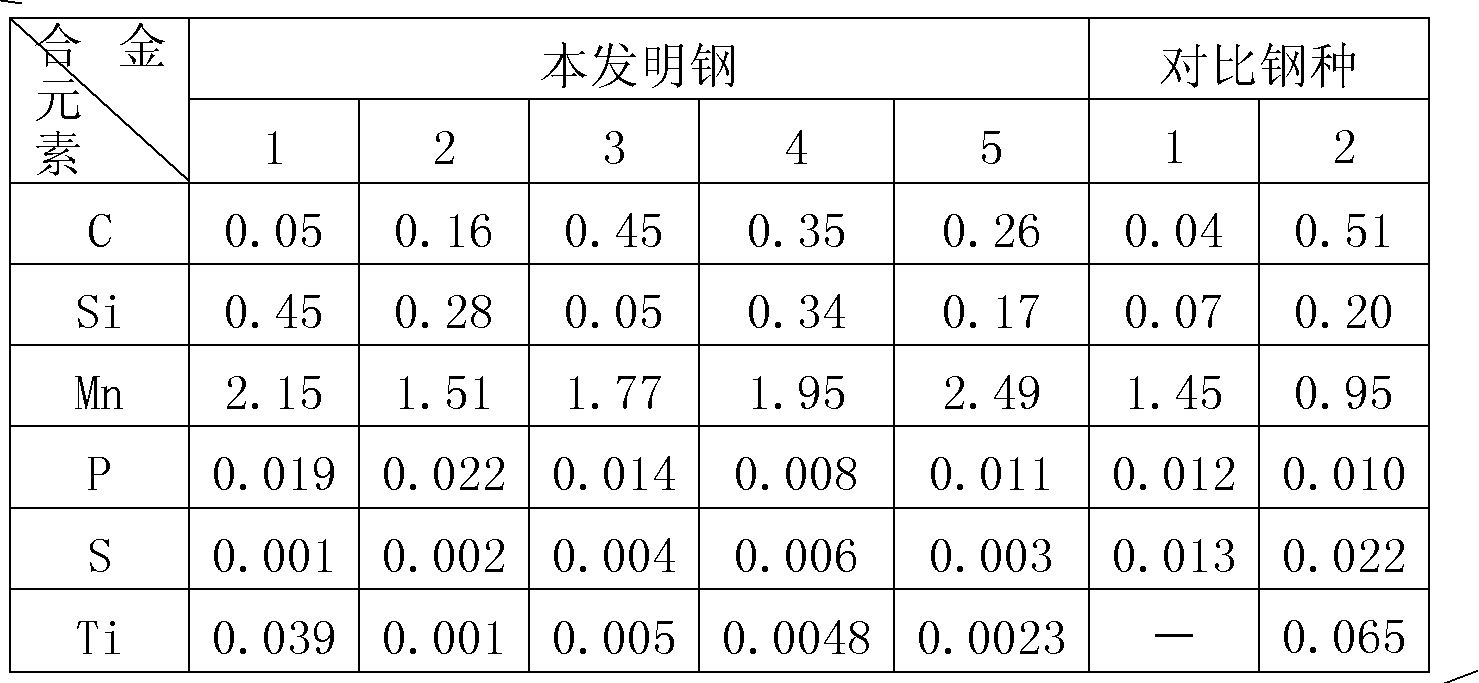

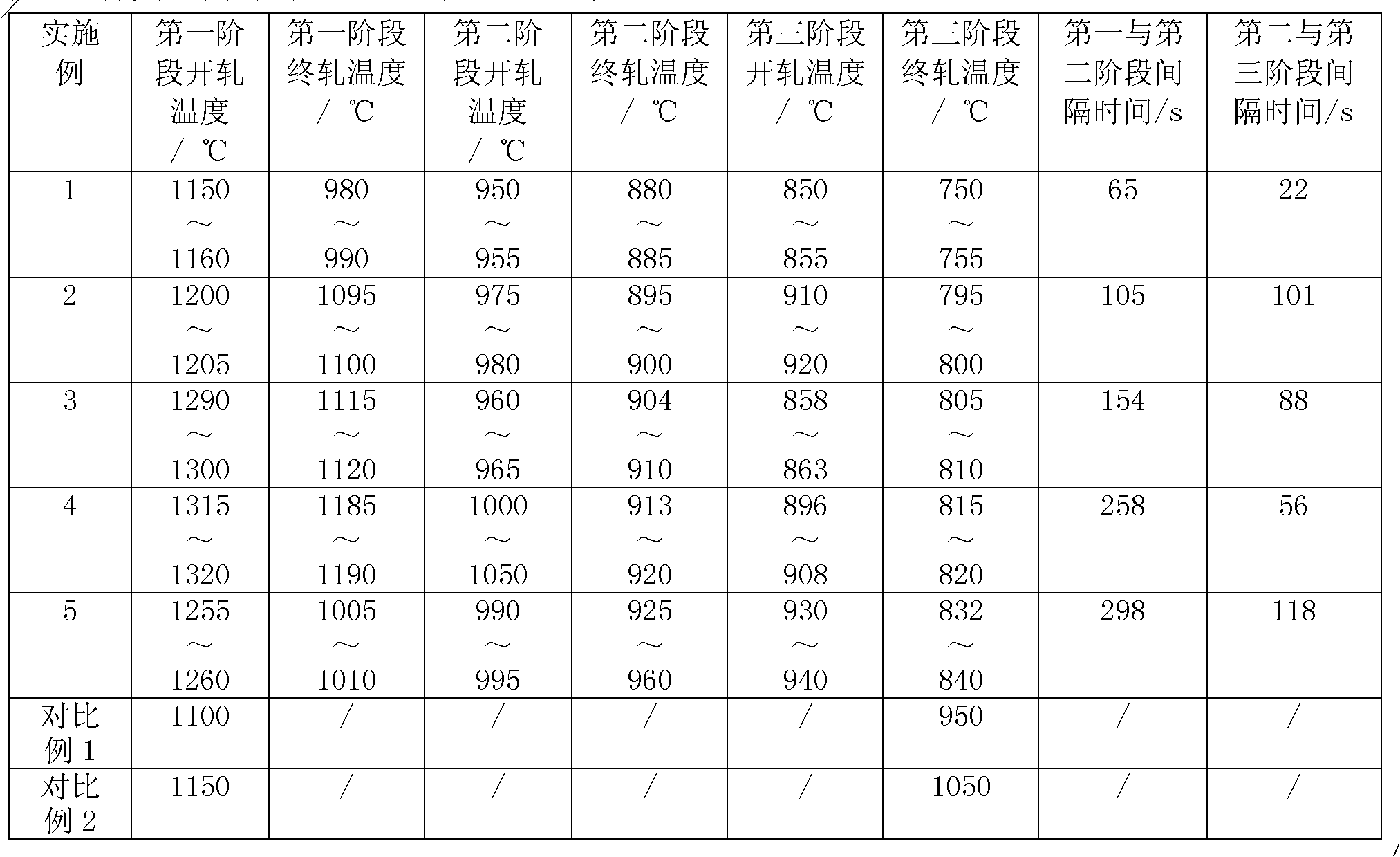

[0024] Carry out five batches of tests and two comparative examples research, its each embodiment and the composition of comparative example and weight percent value are shown in Table 1, and the production technology main parameter of each embodiment and comparative example is shown in Table 2, each embodiment and comparative example The performance test results of the comparative examples are shown in Table 3.

[0025] The production process is carried out according to the following steps:

[0026] 1) Smelting and vacuum treatment, continuous casting into billets;

[0027] 2) Conventional heating and soaking of the billet;

[0028] 3) Rolling in sections: Carry out the first stage, that is, the rolling of the as-cast structure, and control the starting rolling temperature at 1150°C to 1320°C, and control the final rolling temperature at 980°C to 1120°C; after the first stage rolling Within 60 seconds to 300 seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com