Waterproof flame-retardant honeycomb paper board production process

A technology of honeycomb paperboard and production process, which is applied in papermaking, water repellent addition, textile and papermaking, etc., can solve the problems of water resistance, moisture resistance, fire resistance and flame retardant of honeycomb paperboard which are difficult to solve, achieve reliable thermal insulation performance, reduce Production cost, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

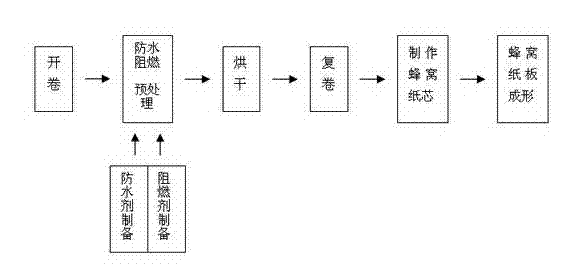

[0031] As shown in the figure, the waterproof and flame-retardant honeycomb paperboard production process of this embodiment includes the following steps:

[0032] (1) Unrolling: roll out the raw material paper roll, lay it up and set it aside for use;

[0033] (2) Waterproof and flame retardant pretreatment: At room temperature, the water repellent, flame retardant and water are mixed according to the weight ratio, water repellent: flame retardant: water = 3:2:4, diluted and mixed evenly to make a pretreatment liquid; Then immerse the unrolled raw paper in the pretreatment solution for soaking treatment, and the soaking time is 4s;

[0034] (3) Drying: Send the raw paper after waterproof and flame-retardant pretreatment into the drying tunnel, and dry and solidify at a temperature of 150°C;

[0035] (4) Rewinding: Rewind the dried raw paper to make a waterproof and flame-retardant raw paper roll for use;

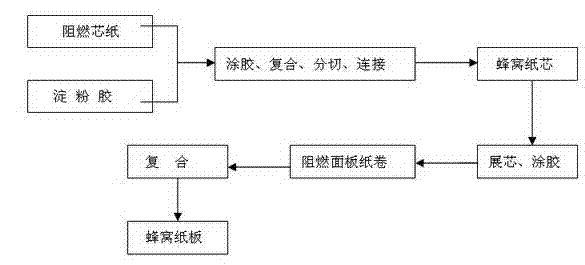

[0036] (5) Production of honeycomb paper core: After the waterproof ...

Embodiment 2

[0051] As shown in the figure, the waterproof and flame-retardant honeycomb paperboard production process of this embodiment includes the following steps:

[0052] (1) Unrolling: roll out the raw material paper roll, lay it up and set it aside for use;

[0053] (2) Waterproof and flame retardant pretreatment: At room temperature, the water repellent, flame retardant and water are mixed according to the weight ratio, water repellent: flame retardant: water = 3:2:4, diluted and mixed evenly to make a pretreatment liquid; Then immerse the unrolled raw paper in the pretreatment solution for immersion treatment, and the immersion time is 5s;

[0054] (3) Drying: Send the raw paper after waterproof and flame-retardant pretreatment into the drying tunnel, and dry and solidify at a temperature of 160°C;

[0055] (4) Rewinding: Rewind the dried raw paper to make a waterproof and flame-retardant raw paper roll for use;

[0056] (5) Production of honeycomb paper core: After the waterpr...

Embodiment 3

[0071] As shown in the figure, the waterproof and flame-retardant honeycomb paperboard production process of this embodiment includes the following steps:

[0072] (1) Unrolling: roll out the raw material paper roll, lay it up and set it aside for use;

[0073] (2) Waterproof and flame retardant pretreatment: At room temperature, the water repellent, flame retardant and water are mixed according to the weight ratio, water repellent: flame retardant: water = 3:2:4, diluted and mixed evenly to make a pretreatment liquid; Then immerse the unrolled raw paper in the pretreatment solution for soaking treatment, and the soaking time is 6s;

[0074] (3) Drying: Send the raw paper after waterproof and flame-retardant pretreatment into the drying tunnel, and dry and solidify at a temperature of 170°C;

[0075] (4) Rewinding: Rewind the dried raw paper to make a waterproof and flame-retardant raw paper roll for use;

[0076] (5) Production of honeycomb paper core: After the waterproof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com