A kind of double-layer straight core plywood and its manufacturing method

A plywood, core-shunting technology, used in adhesives, manufacturing tools, adhesive types, etc., can solve the problems of the need to improve the bonding strength and the high cost of raw materials with formaldehyde content, to improve the flame retardant performance and the opening time of the board, the preparation process And the effect of simple and feasible preparation equipment, improving performance and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A double-layer straight-core plywood, which is composed of a face plate, a core board and a bottom board from top to bottom, which are formed by hot pressing with an adhesive; Pressed, the wood grain direction of the two middle boards is the same; the adhesive is prepared according to the following process:

[0018] 1) Weigh 1 part of potassium methyl silicate, 2 parts of sodium lauryl sulfate, 2 parts of hydroxyethyl cellulose, 3 parts of zinc stearate, 3 parts of boric acid, 3 parts of montmorillonite, lithium 4 parts of base bentonite, 5 parts of silica gel powder, 5 parts of wheat straw, 7 parts of borax, 20 parts of starch ether, 25 parts of polyvinyl alcohol, 50 parts of methyl acrylate, 70 parts of ethyl acrylate, and 600 parts of distilled water;

[0019] 2) Crush the wheat straw with a pulverizer, and then grind it into a powder with a particle size of 200 mesh;

[0020] 3) Add montmorillonite, lithium-based bentonite and borax to the ball mill in turn, grind ...

Embodiment 2

[0025] A double-layer straight-core plywood, which is composed of a face plate, a core board and a bottom board from top to bottom, which are formed by hot pressing with an adhesive; Pressed, the wood grain direction of the two middle boards is the same; the adhesive is prepared according to the following process:

[0026] 1) Weigh 2 parts of potassium methyl silicate, 3 parts of sodium lauryl sulfate, 3 parts of hydroxyethyl cellulose, 5 parts of zinc stearate, 5 parts of boric acid, 5 parts of montmorillonite, lithium 7 parts of base bentonite, 9 parts of silica gel powder, 9 parts of wheat straw, 12 parts of borax, 30 parts of starch ether, 35 parts of polyvinyl alcohol, 80 parts of methyl acrylate, 110 parts of ethyl acrylate, and 1000 parts of distilled water;

[0027] 2) Crush the wheat straw with a pulverizer, and then grind it into a powder with a particle size of 200 mesh;

[0028] 3) Add montmorillonite, lithium-based bentonite and borax to the ball mill in turn, gr...

Embodiment 3

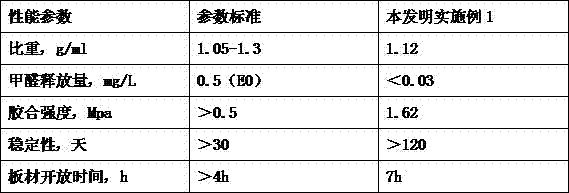

[0033] The performance parameter test of adhesive of the present invention:

[0034] With reference to GB / T9846.3-2004 and GB / T14074-2006 standard testing, taking Example 1 as an example, the specific testing results are shown in Table 1:

[0035] Table 1

[0036]

[0037] Conclusion: The adhesive prepared by the invention is environmentally friendly and pollution-free, has strong bonding strength, good stability, long board opening time, and is suitable for plywood processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com