Composite prestressed bar finished guy cable and manufacturing method thereof

A technology for finished rib and prestress, applied in the field of composite prestressed rib finished cable and its preparation, can solve the problems of high quality control requirements in the construction process, difficult anti-corrosion work, complicated construction steps, etc. Homogeneous stress cracking, improving the ability to resist wind and rain vibration, and avoiding the effects of simultaneous corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

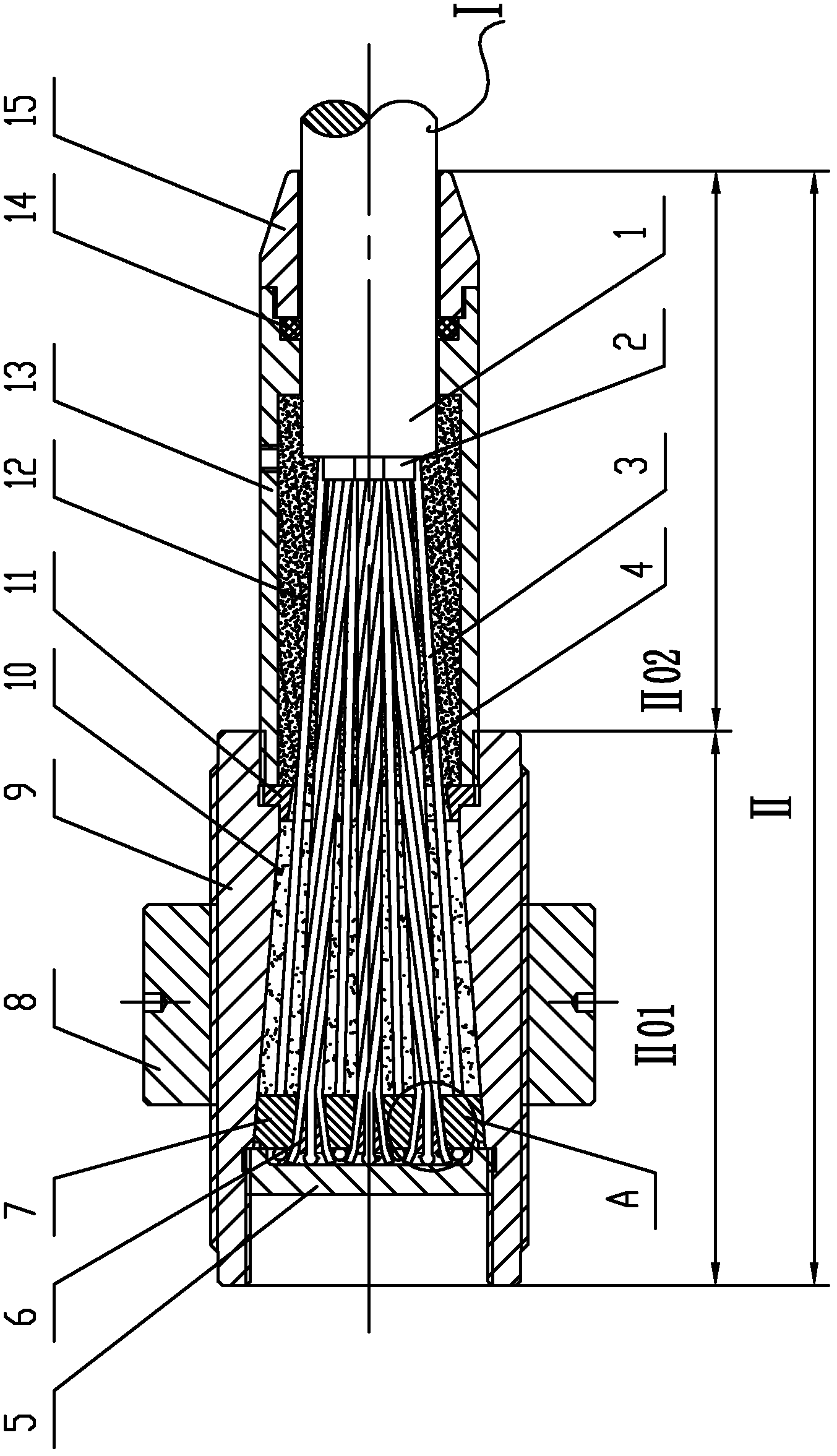

[0052] A composite prestressed tendon finished cable composed of isolated anti-corrosion steel strands, including a cable body I and two anchor pieces II located at both ends of the cable body I. The cable body I includes 7 single-strand steel strands 4 and 6 steel wires 3 for the composite prestressed steel finished cable body; each anchor includes anchoring unit Ⅱ01 and sealing unit Ⅱ02 (see figure 1 );

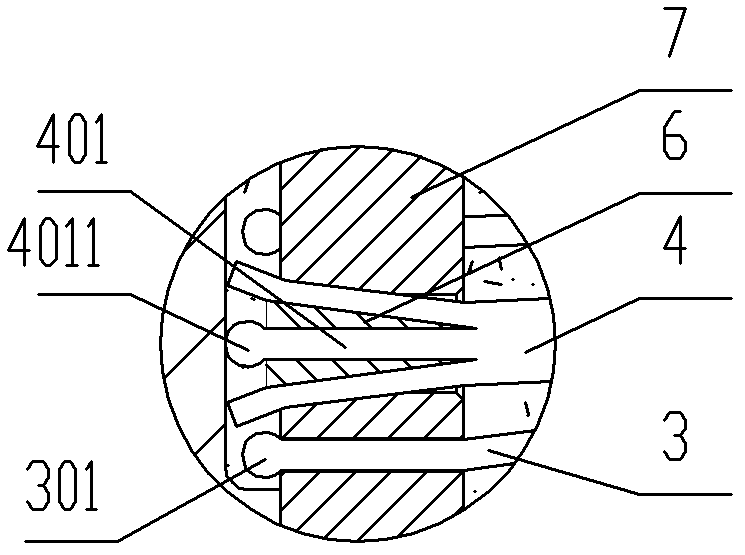

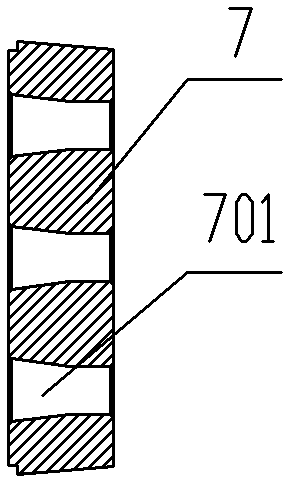

[0053] The anchor unit II01 includes an end cap 5, a taper sleeve 6, an anchor plate 7, a nut 8, an anchor cup 9 and a restraint ring 11; the anchor plate 7 has a plurality of tapered anchor holes 701 for anchoring a single-strand steel strand And the through hole for anchoring the cable steel wire 3, after the 7 single-strand steel strands 4 and 6 cable steel wires 3 that constitute the composite prestressed tendon finished cable body I pass through the anchor cup 9, each single-strand steel strand The wires respectively penetrate into the corresponding tapered anchor ho...

Embodiment 2

[0060] A manufacturing method of a composite prestressed tendon finished cable described in Embodiment 1. Its production process includes the following steps:

[0061] A. Remove a length of the sheath from one end of the composite prestressed tendon finished cable body I consisting of n single-strand steel strands 4 and p cable steel wires 3, and clean the surface of each single-strand steel strand 4;

[0062] B. Pass the cleaned n single-strand steel strands 4 and p stay cable steel wires 3 through the anchor cup 9, each single-strand steel strand 4 respectively penetrates into the tapered anchor hole 701 of the anchor plate 7, and The center wire 401 of each single-strand steel strand 4 is covered with a taper sleeve 6, and the center wire is subjected to heading processing to form an upsetting head 4011, and the remaining m-1 side wires are located outside the taper sleeve 6 and are tapered Scattered and distributed with the tapered anchor hole of the anchor plate 7 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com