Intelligent automatic speed change control system for loading machine and control method for intelligent automatic speed change control system

An automatic transmission and control system technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of increased shifting process, shifting lag, and gears that cannot be kept up. problems, to achieve efficient automatic transmission control, avoid shift lag, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

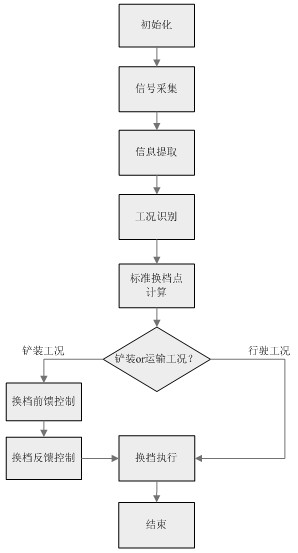

[0056] The following describes this embodiment in detail with reference to the drawings:

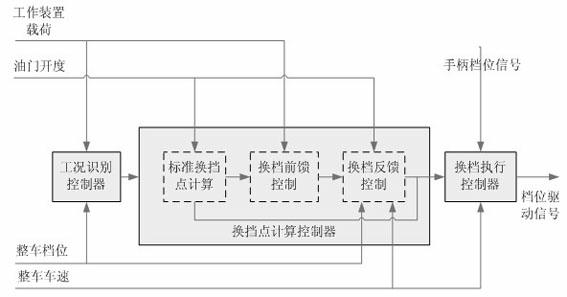

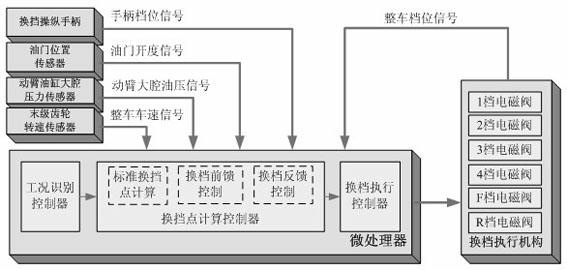

[0057] Attached figure 2 It is a structural block diagram of this embodiment using the front 4 rear 3 automatic transmission embodiment.

[0058] The working condition recognition controller, the shift point calculation controller (including standard shift point calculation, shift feedforward control, and shift feedback control), and the shift execution controller are programmed in the microprocessor. Throttle position sensor, transmission final gear speed sensor, boom oil cylinder large cavity oil pressure sensor respectively output the throttle opening signal, vehicle speed signal and boom oil cylinder large cavity oil pressure signal to the microprocessor, and the shift joystick output The gear position signal of the handle is sent to the microprocessor, and the solenoid valve of each gear of the shift actuator feedbacks the gear position of the whole vehicle to the microprocessor. The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com