Self-changing gearbox protective agent and preparation method thereof

An automatic transmission and protective agent technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of unreasonable selection and ratio of additives, increased wear of couplings and other components, and inability to protect automatic transmissions, so as to reduce sludge and the production of paint film, product safety and stability, and the effect of improving shift smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

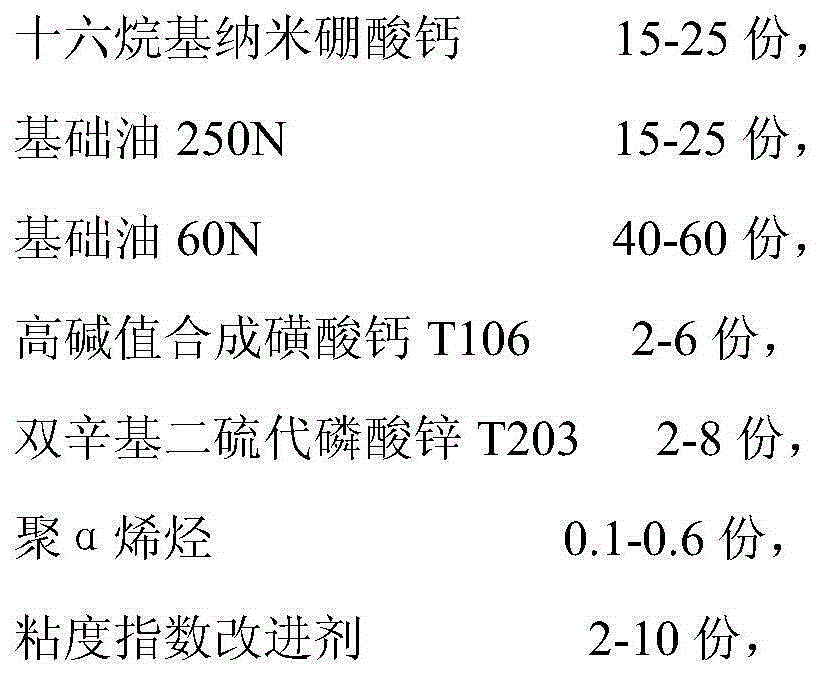

[0025] A protective agent for automatic transmission, comprising the following components by weight:

[0026]

[0027]

[0028] The preparation method of above-mentioned automatic transmission protective agent is characterized in that, comprises the following steps:

[0029] (1) Add base oil 250N, base oil 60N and cetyl nano-calcium borate into the mixing kettle respectively, stir evenly, the stirring speed is 500 rpm, and the stirring time is 20 min;

[0030] (2) Add high base value synthetic calcium sulfonate T106, bis-octyl zinc dithiophosphate T203, polyalphaolefin T803B, viscosity index improver SV-261 and lubricating oil antifoaming agent T901 into the mixing kettle in sequence, and stir Uniform, that is, the stirring speed is 500 rpm, and the stirring time is 50min.

Embodiment 2

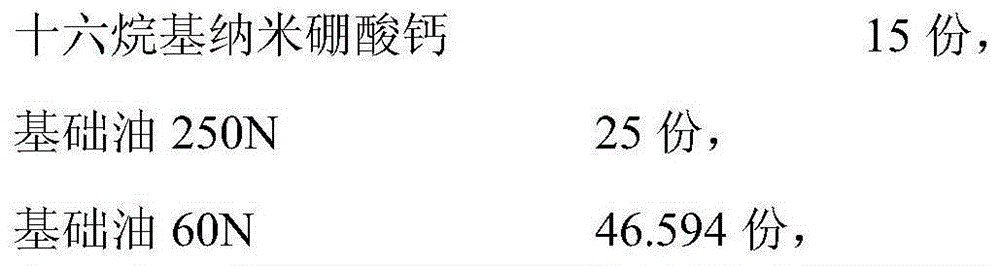

[0032] A protective agent for automatic transmission, comprising the following components by weight:

[0033]

[0034] The preparation method of above-mentioned automatic transmission protective agent is characterized in that, comprises the following steps:

[0035] (1) Add base oil 250N, base oil 60N and cetyl nano-calcium borate into the mixing kettle respectively, stir evenly, the stirring speed is 600 rpm, and the stirring time is 20 min;

[0036] (2) Add high base value synthetic calcium sulfonate T106, bis-octyl zinc dithiophosphate T203, polyalphaolefin T803B, viscosity index improver SV-261 and lubricating oil antifoaming agent T901 into the mixing kettle in sequence, and stir Uniform, that is, the stirring speed is 600 rpm, and the stirring time is 40min.

Embodiment 3

[0038] A protective agent for automatic transmission, comprising the following components by weight:

[0039]

[0040]

[0041] The preparation method of above-mentioned automatic transmission protective agent is characterized in that, comprises the following steps:

[0042] (1) Add base oil 250N, base oil 60N and cetyl nano-calcium borate into the mixing kettle respectively, stir evenly, the stirring speed is 700 rpm, and the stirring time is 15 min;

[0043] (2) Add high base value synthetic calcium sulfonate T106, bis-octyl zinc dithiophosphate T203, polyalphaolefin T803B, viscosity index improver SV-261 and lubricating oil antifoaming agent T901 into the mixing kettle in sequence, and stir Uniform, that is, the stirring speed is 700 rpm, and the stirring time is 40min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com