Glass block cladding mounting structure

A technology for installing structures and glass bricks, applied in building construction, covering/lining, construction, etc., can solve the problems of single glass bricks, long construction period, hidden safety hazards, etc., to overcome the disadvantages of construction noise and dust pollution, and ensure quietness and tidy, the effect of eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

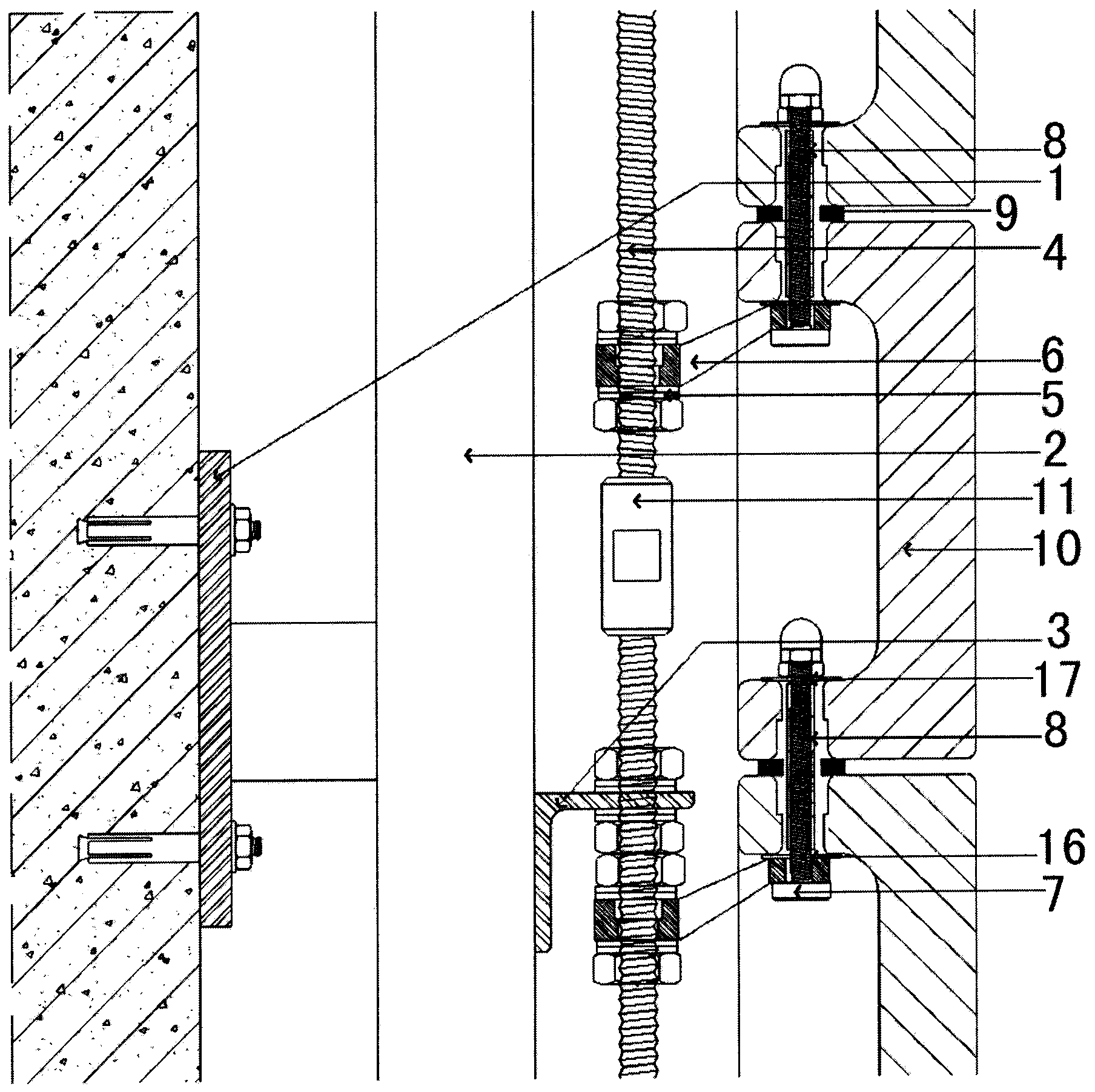

[0025] Example: such as figure 1 As shown, a glass brick dry-hanging installation structure includes a pre-embedded plate 1, a channel steel 2, an angle steel 3, a screw rod 4, a single barge 6, a glass brick 10, and a screw rod adapter 11. The embedded board 1 is fixed to the wall foundation, and the angle steel 3 is provided with a screw hole for the screw rod 4 to pass through, and the screw rod 4 is connected and fixed on the angle steel 3 . The threaded mandrel 4 is connected with the threaded mandrel 4 through a threaded mandrel adapter 11 . The single barge 6 is pierced on the screw mandrel 4, and the single barge 6 is fixed on the upper limit of the screw mandrel 4 by the screw. The glass bricks 10 are provided with holes, and the holes of adjacent glass bricks 10 correspond to each other so that the bolts 7 can pass through and be fixed on the single barge 6 together. A plastic sleeve 8 is arranged between the bolt 7 and the hole of the glass block 10 . A plastic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com