Planetary gear transmission supercharger

A technology of planetary gear transmission and supercharger, which is applied in the direction of gear transmission, transmission, gear lubrication/cooling, etc., and can solve the problems of low exhaust gas energy, weakened starting and acceleration capabilities, and insufficient air supply demand of the supercharger. , to eliminate hysteresis and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

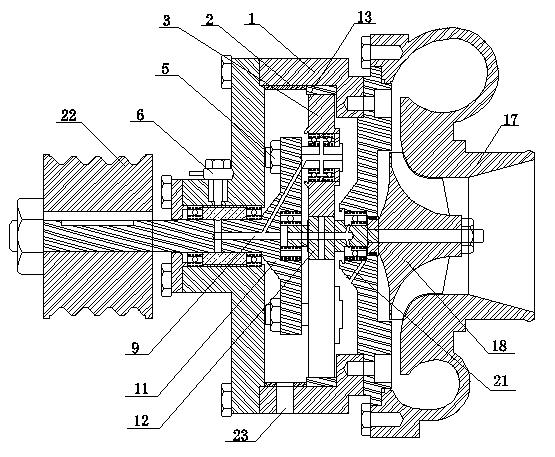

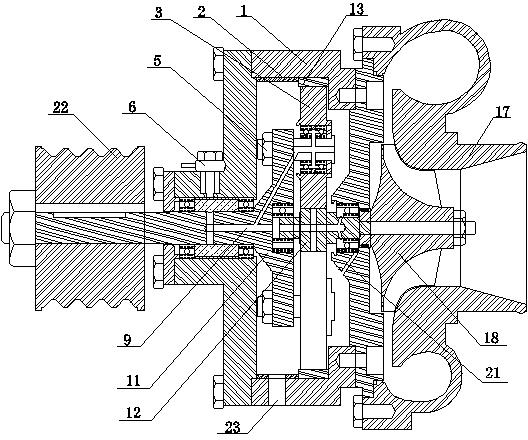

[0014] Such as figure 1 It is a schematic structural diagram of the present invention, a planetary gear transmission supercharger, including a housing 1, a pulley 22, a housing 17 and an impeller 18, the belt pulley 22 is connected to the left side of the housing 1, and the housing 17 is connected to the housing 1 On the right side, the pressure impeller 18 is installed in the cavity of the casing 17, and the planetary gear 3, the sun gear 12, the internal gear 13 and the bracket shaft 11 are arranged in the housing 1, and the internal gear 13 is connected to the housing 1 through the inner ring 2 of the housing. On the circumference of the inner wall, the planetary gear 3 is installed on the bracket shaft 11 through the connecting rod 5, and is meshed with the sun gear 12 and the inner ring gear 13 respectively. The front end of the housing 1 is provided with an oil inlet joint column 6, and the rear end is provided with an oil discharge hole. 21. The bottom is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com