Controller, floating type wind driven generation unit and control method thereof

A wind turbine, floating technology, applied in the direction of wind turbine components, wind engine control, wind motor combination, etc., can solve the problems of high installation space, maintenance space, cost increase, large load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, therefore, the present invention is not limited to the specific embodiments disclosed below limit.

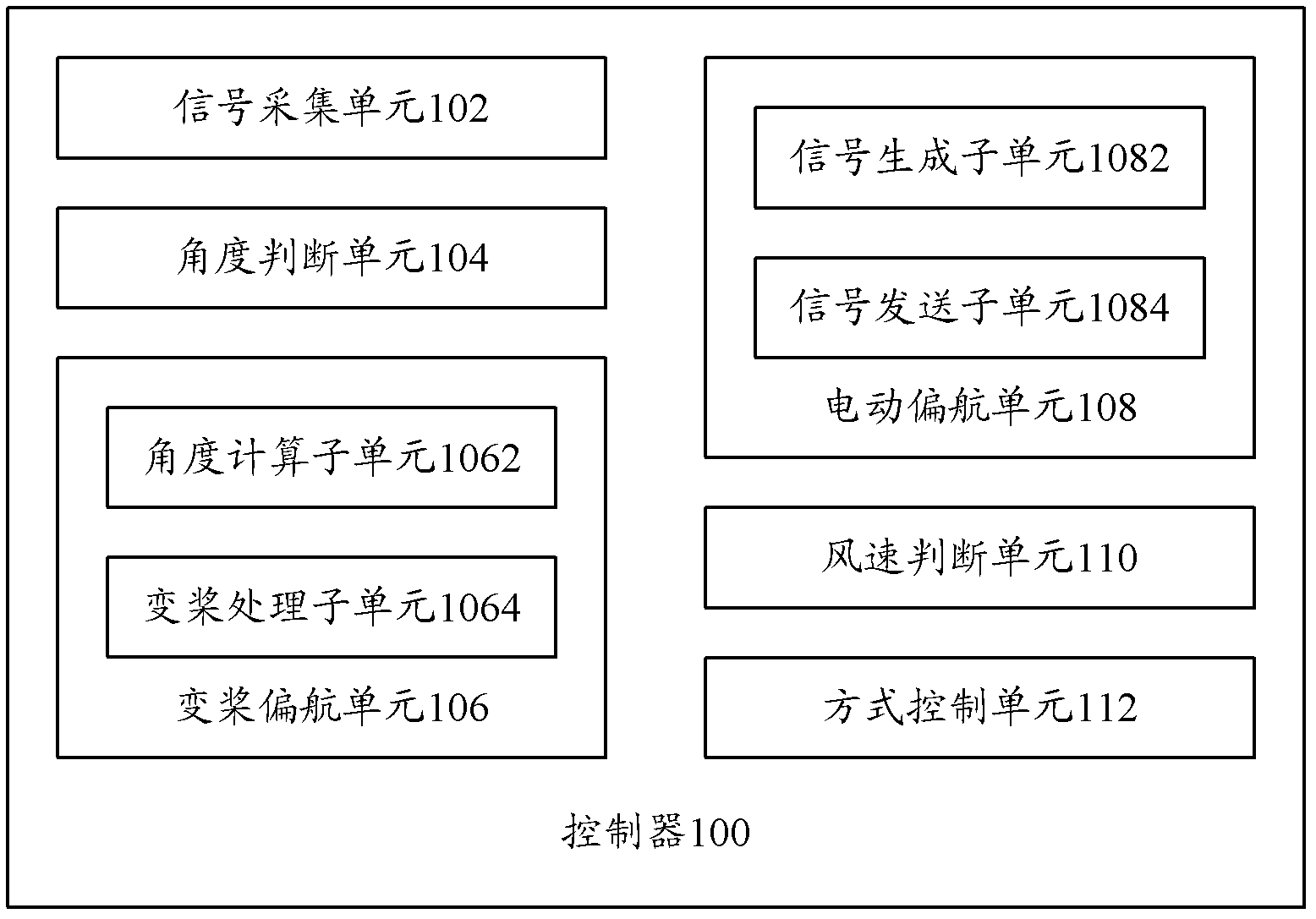

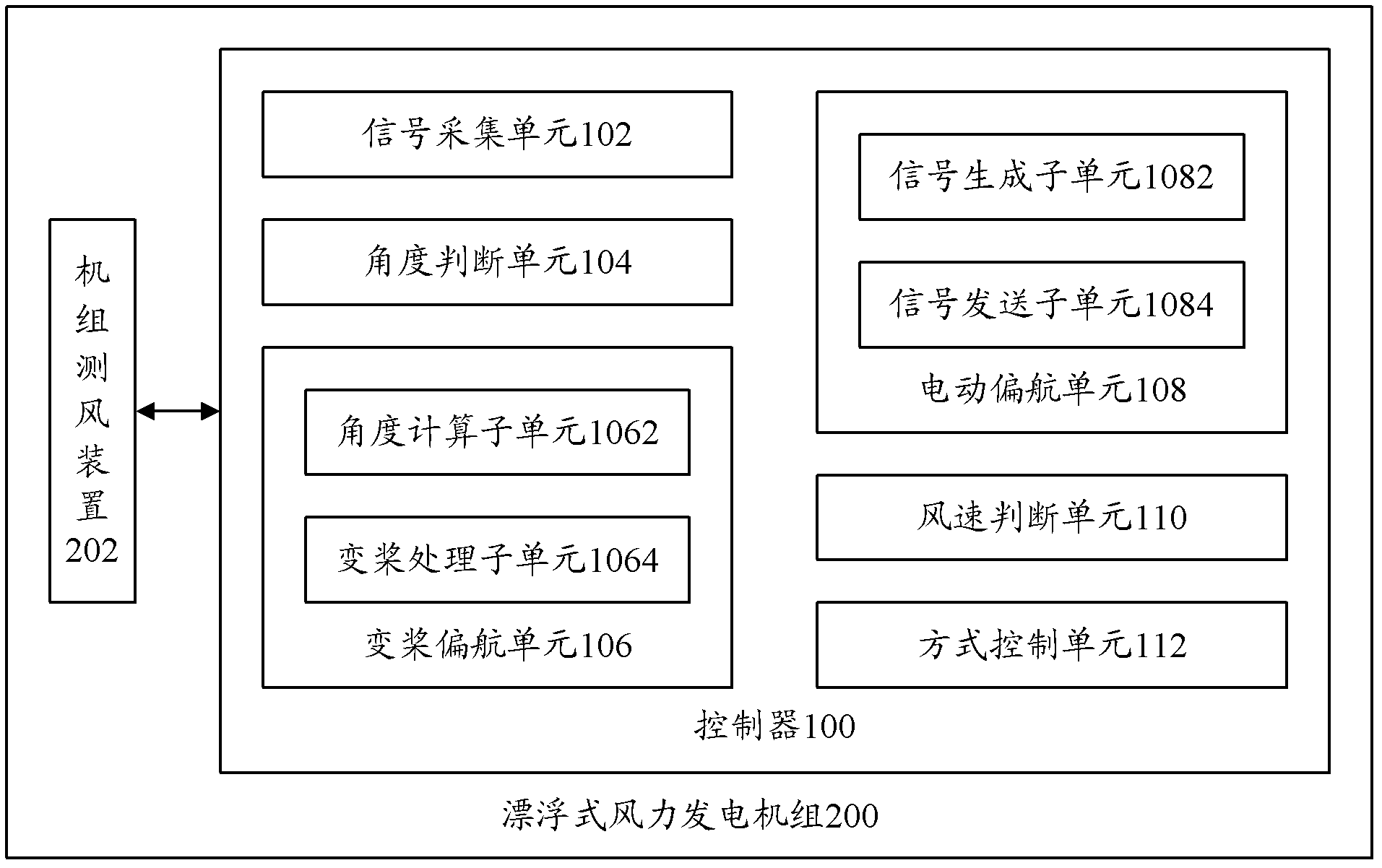

[0042] figure 1 A block diagram of a controller according to the invention is shown.

[0043] Such as figure 1 As shown, the controller 100 according to the present invention is used for a floating wind power generating set. The floating wind power generating set includes two or more wind generating sets, and the wind generating set takes the longitudinal axis of the tower as the axis of symmetry ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap