Self-control two-way direct-current low-voltage electric temperature control valve

A dual-channel direct current, temperature-controlled valve technology, applied to valve details, valve devices, engine components, etc., can solve problems such as heat waste, radiators, heating pipes freezing, unsafety, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

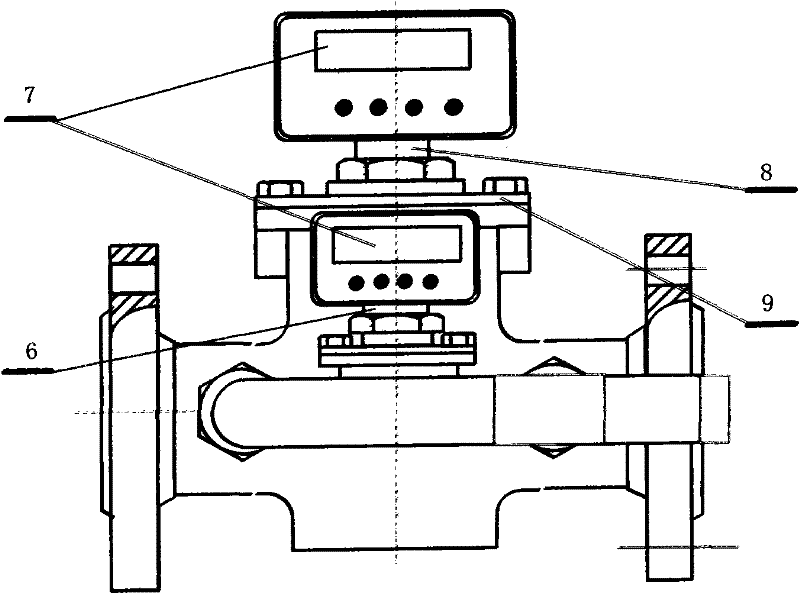

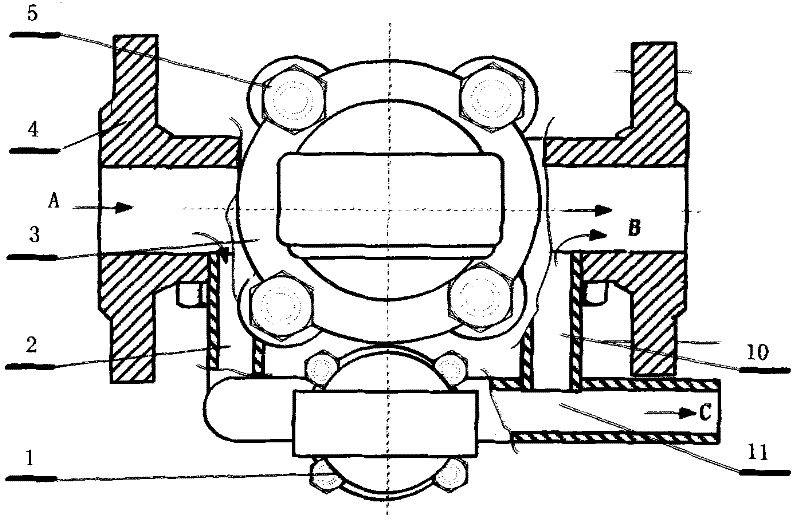

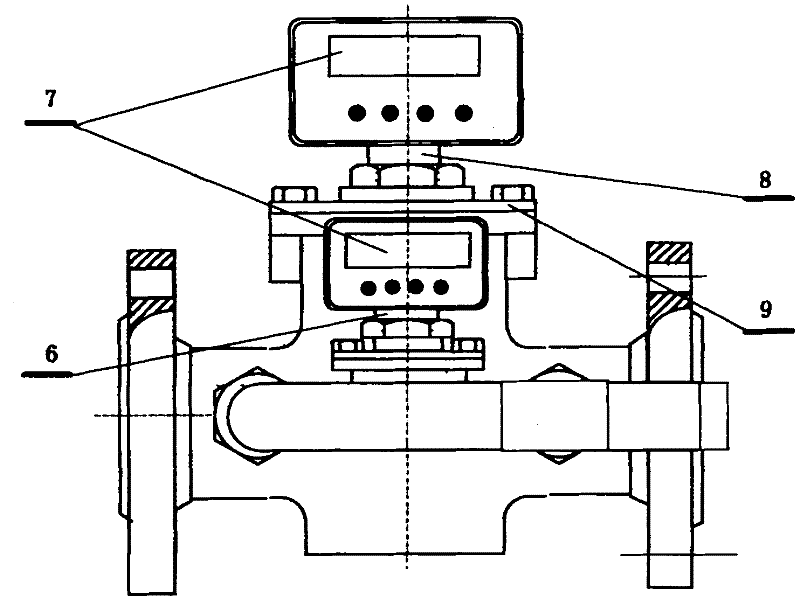

[0008] This embodiment is applied in the heating system, and the structure is shown in the accompanying drawings, mainly including branch valve (1), branch water inlet pipe (2), main valve (3), valve body (4), connecting bolts (5), Linkage set (16), control box (7), linkage set 2 (8), valve cover (9), branch water outlet 1 (10), branch water outlet 2 (11); main valve ( 3). The branch valves (1) are all installed on the valve body (4). The opening or closing of the valve is designed as a pilot type: the piston on the valve core controls the closing of the pressure relief port, and the pressure difference in the valve is used to realize the pressure relief in the valve. The piston of the main outlet of the main water outlet moves to open or close the valve; the two ends of the pressure relief port are respectively connected with the upper water cavity and the outlet pipe of the valve; the water inlet of the branch valve (1) is connected with the water inlet in the valve body, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com