Connecting assembly for combining hydraulic components

A technology for connecting sleeves and hydraulic machinery, which is applied in the hydraulic field and can solve problems such as inability to insert connecting sleeves and small manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

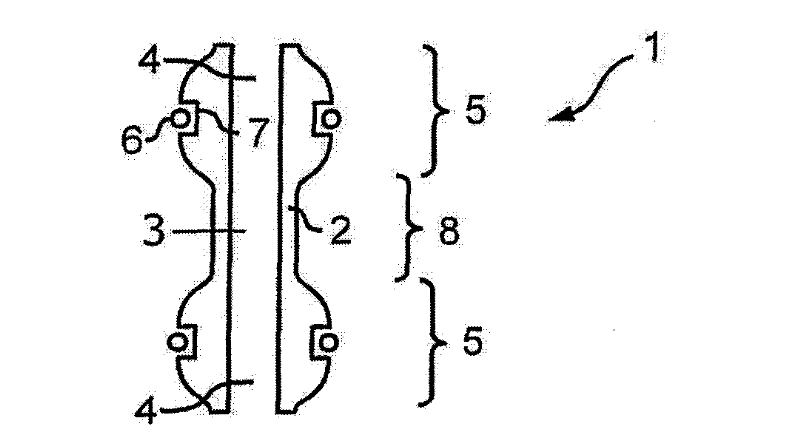

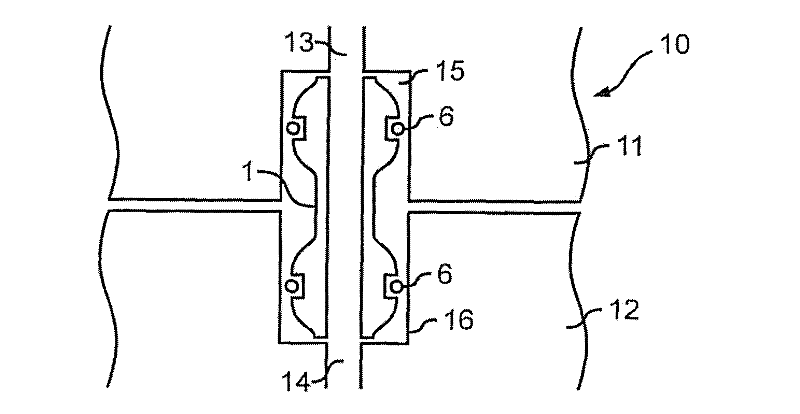

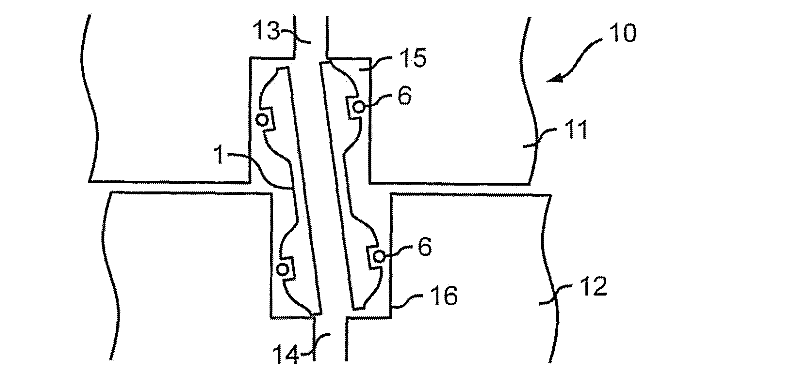

[0035] figure 1 A schematic cross-sectional view of a connecting sleeve 1 according to an embodiment of the present invention is shown in FIG. The connecting sleeve 1 has a cylindrical sleeve body 2 which encloses a cavity 3 . The sleeve body 2 is open on its front end face 4 so as to form a connection channel for conducting hydraulic fluid. The cross-section of the cavity 3 can basically be of any shape, but a connecting sleeve with a circular cross-section is usually used, enabling insertion in all directions of rotation.

[0036] In most cases, a sealing area 5 is provided at one end of the connecting sleeve 1 . In this sealing area 5, the diameter of the sleeve body 2 is thickened, so that the diameter of the sleeve body 2 on the sealing area 5 (transversely with respect to the axial direction) is larger than that of the sleeve remote from the corresponding end section The diameter of the sleeve body 2 in the intermediate region 8 of the tube body 2 . According to actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com