An oxide thin film transistor, array substrate and display device

A technology of oxide thin films and transistors, which is applied in the direction of transistors, electric solid-state devices, semiconductor devices, etc., can solve the problems of low mobility and poor stability, and achieve the effect of improving TFT mobility and carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

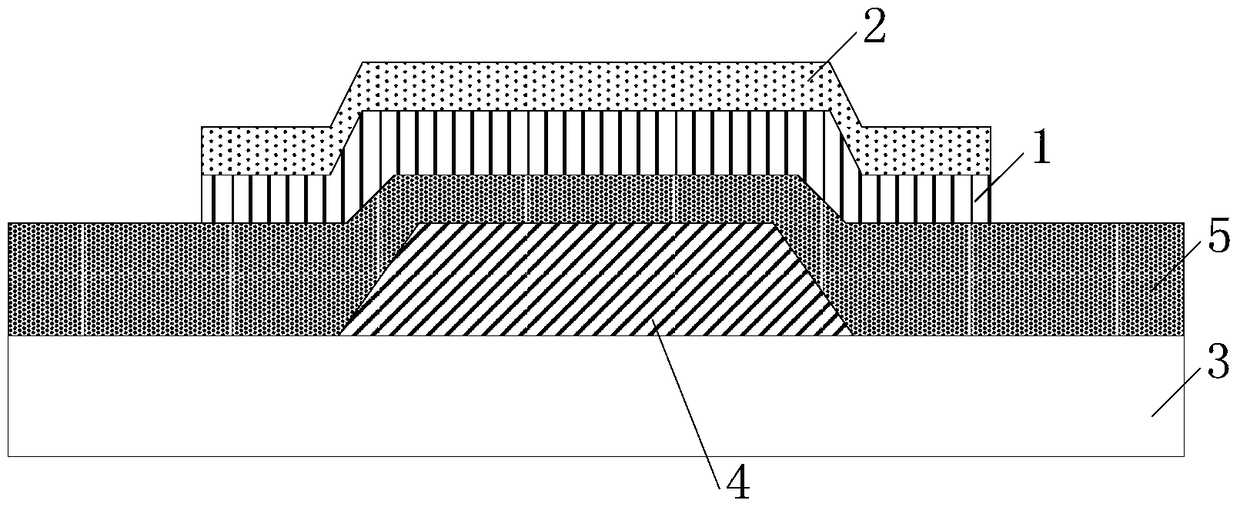

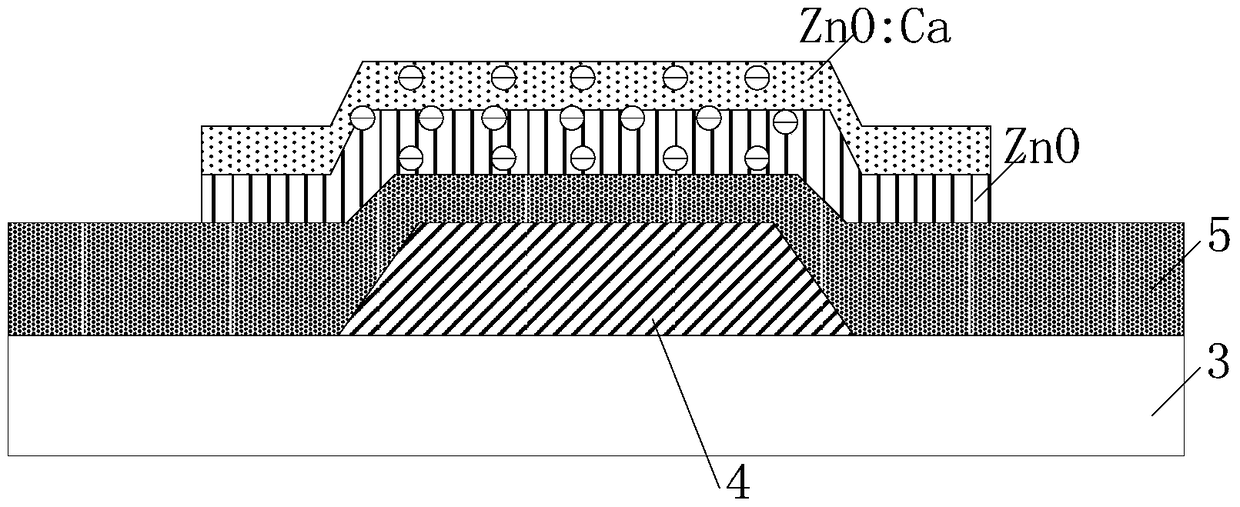

[0042] Embodiment 1 of the present invention provides an oxide thin film transistor, which is a ZnO system TFT with a bottom gate structure. The back channel oxide layer 2 is an ion-doped ZnO system with a large band gap, and the front channel oxide layer 1 is an ion-doped or non-ion-doped ZnO system with a small band gap.

[0043] Among them, a front channel oxide layer 1 is deposited on the gate insulating layer 5, which is a ZnO system material, and then a back channel oxide layer 2 formed by a low work function ion-doped ZnO system material is deposited, marked as ZnO: M, where M represents doped metal ions, which can be Ca with low work function 2+ or Mg 2+ and other metal ions. In this embodiment 1, metal Ca is exemplified 2+ , recorded as ZnO: Ca.

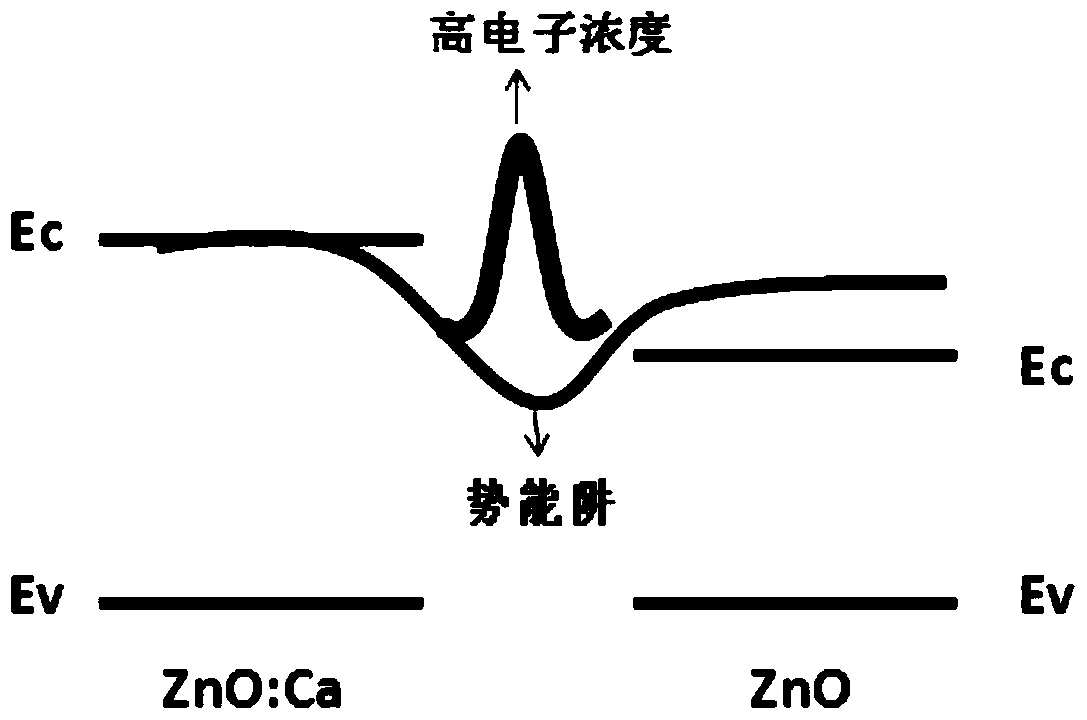

[0044] The ZnO system material in this embodiment 1 can be ZnO or ion-doped zinc oxide system material, such as: IGZO, ITZO and other materials. Among them, since the bandgap (Eg) of calcium oxide CaO is 7.1eV, and the ...

Embodiment 2

[0049] Embodiment 2 of the present invention provides an oxide thin film transistor, and the materials of the back channel oxide layer 2 and the front channel oxide layer 1 are different.

[0050] Among them, the front channel oxide layer 1 is deposited on the gate insulating layer 5, and a ZnO system material with a small forbidden band width and a low conduction band energy level is deposited on this layer, and the forbidden band width of the ZnO system is ~ 3eV; then ZrO is deposited. 3 System material, ZrO 3 The bandgap width of ~5.5eV, due to ZnO and ZrO 3 The conduction band energy level difference and the forbidden band width difference, electrons are composed of ZrO 3 transfer to ZnO, and in ZrO 3 / ZnO interface forms a potential energy well, see Figure 4 , the electron concentration accumulated in the potential energy well is the highest, and the interface potential energy well with the highest electron concentration becomes the main channel for electron transport...

Embodiment 3

[0053] Embodiment 3 of the present invention provides an array substrate, including the oxide thin film transistor described in any one of the above items.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com