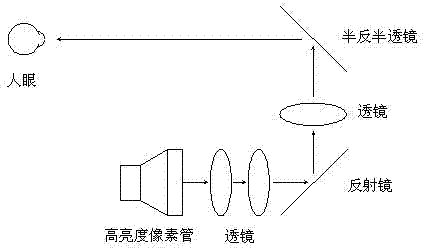

Low-power extremely-high-brightness LED (light emitting diode) backlight source used for liquid crystal projection display system

A technology of display system and liquid crystal projection, applied in the field of lighting light source and optics, can solve the problems of low power and brightness, complex configuration, high power, etc., and achieve the effects of improving uniformity, short design cycle and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

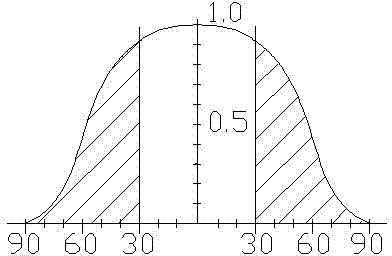

[0025] control figure 2 , the light energy (shaded part) outside the range of spherical angle ±30° accounts for about 70% of the total luminous flux. It can be calculated by formula (1), in Φ In the case of constant luminous flux, if the LED light with approximate Lambertian distribution (equivalent to θ is 120°) is focused to within ±30° (equivalent to θ is 60°), the light intensity at the frontal angle of 0° I theoretically can be increased to 3.73 times the original brightness. Therefore, adding a reflective bowl can greatly increase the brightness of the backlight; or to achieve the same brightness of the backlight, the power can be reduced to less than 30% of the original;

[0026]

[0027] In formula (1), Φ is the luminous flux (unit Lm), and I is the light intensity at 0 degree angle (unit cd). θ is 2θ1 / 2 angle, which is commonly referred to as LED half-brightness angle.

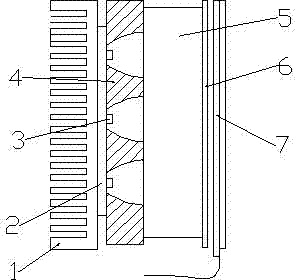

[0028] control image 3 , Figure 4 , LED power (power = current × voltage) is not propo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com