Deign method of light-type controllable lens with double freeform surfaces

A technology of curved surface lens and design method, which is applied in the direction of semiconductor devices, light sources, and point light sources of light-emitting elements, and can solve the problems of losing the freedom of lens design and not being able to adjust the shape of the lens at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

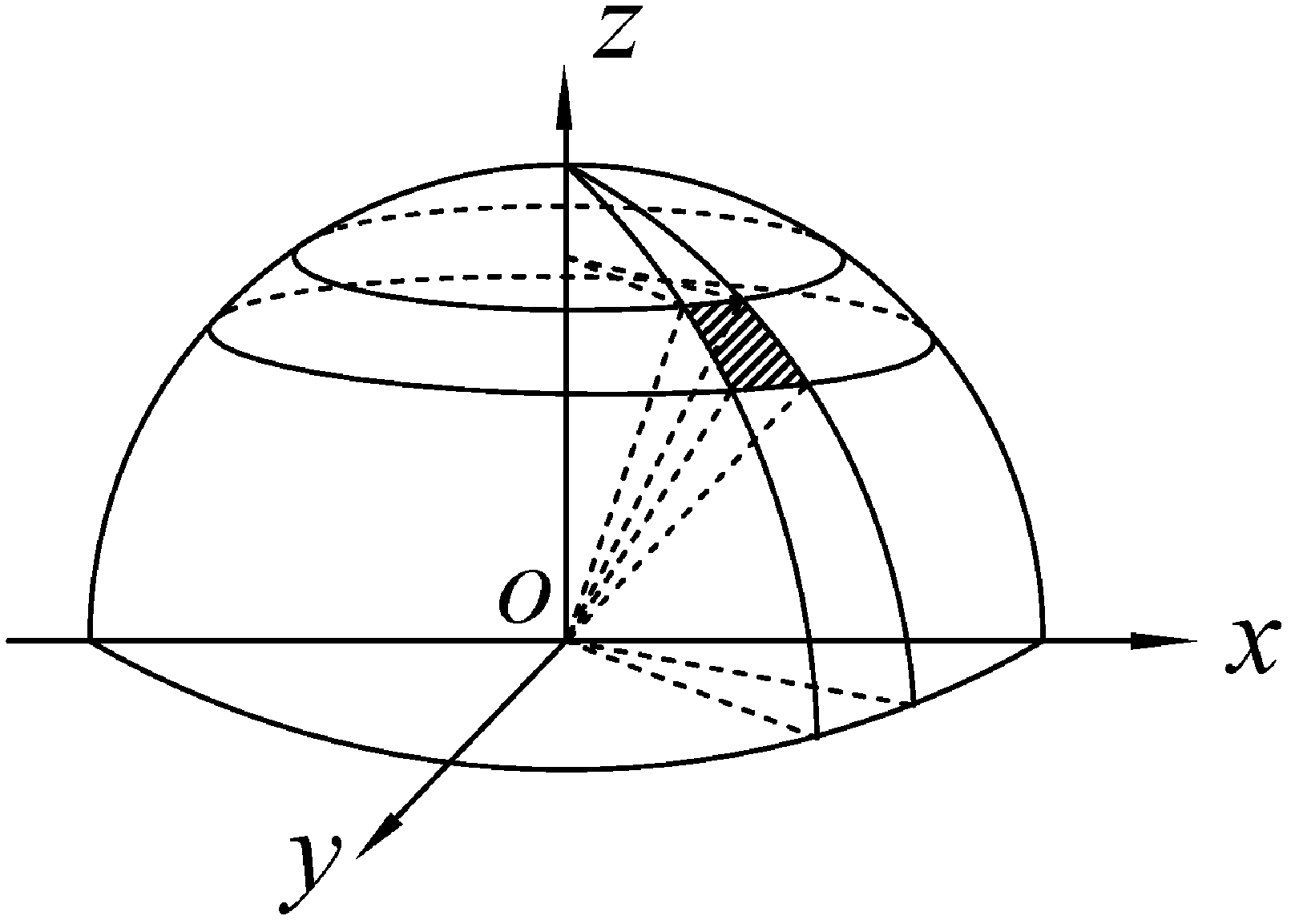

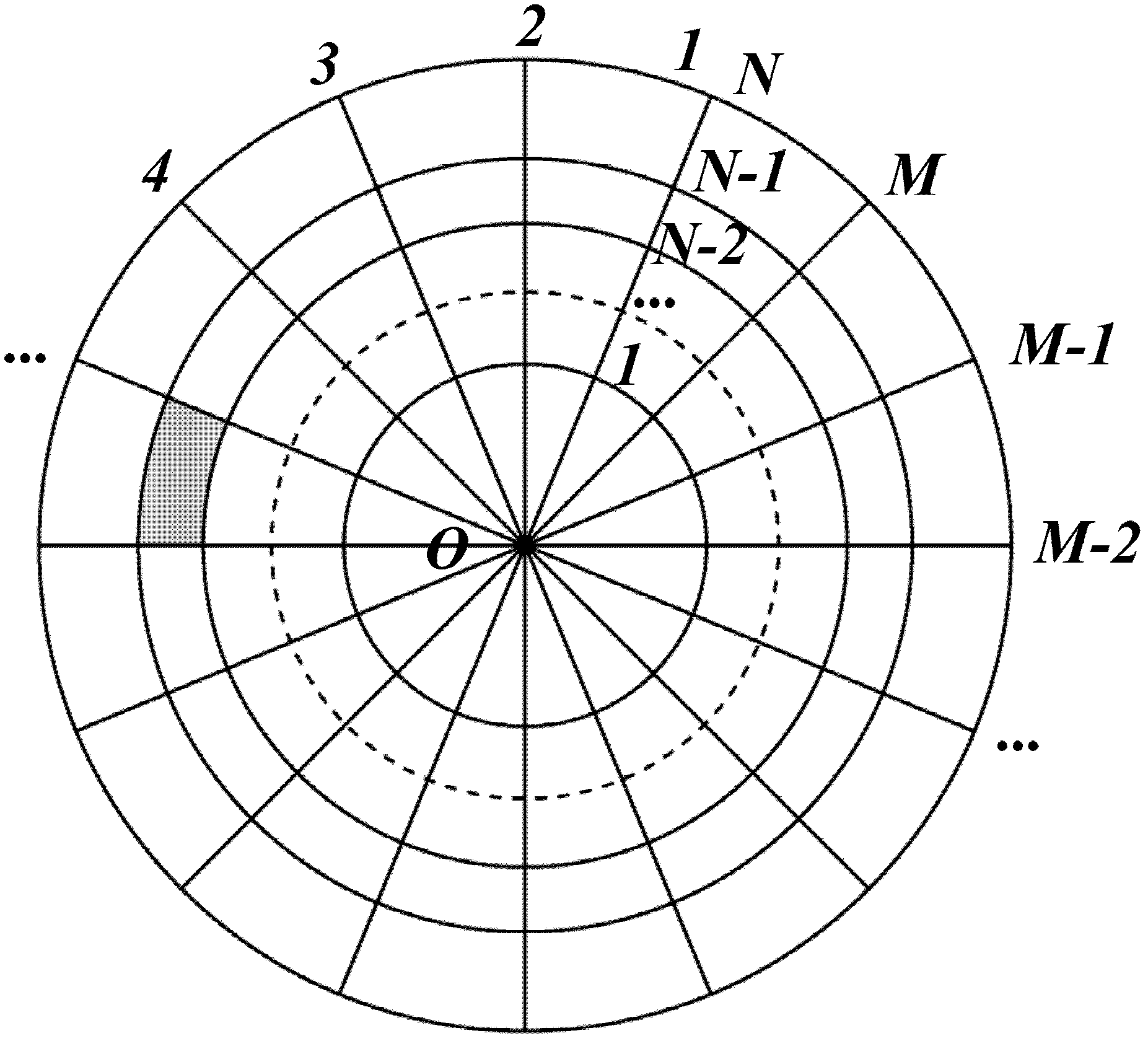

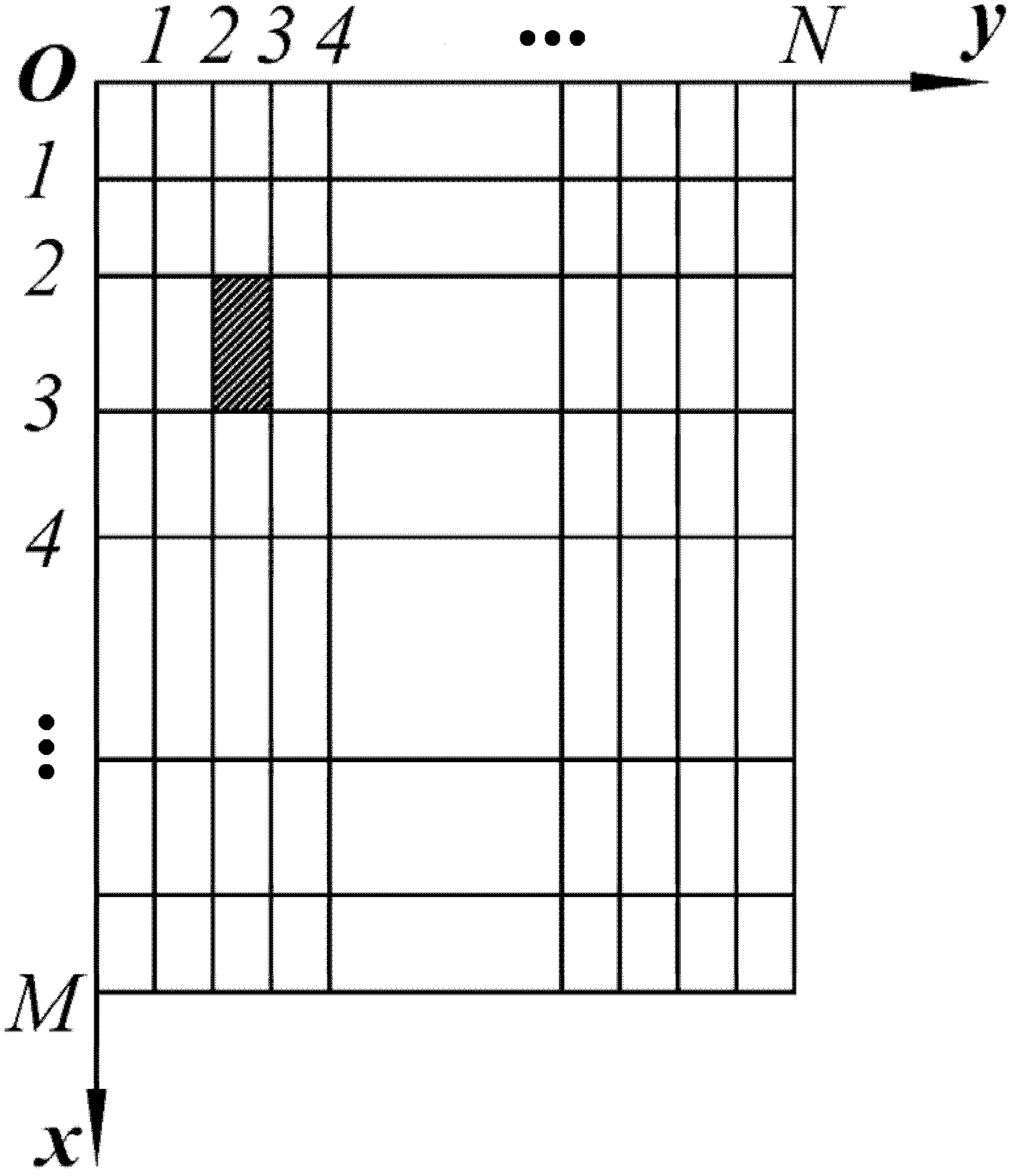

[0046] Referring to FIG. 5(1), this embodiment relates to a rotationally symmetrical double free-form surface lens whose inner surface is cylindrical and outer surface is a free-form surface. The material of double free-form surface lens is PC (polycarbonate) in the present embodiment, and inner surface height is 1 millimeter, and outer surface height is 4 millimeters, and the function relation of given inner surface is 1=x 2 +y 2 (0≤z≤1), that is, a cylinder with a height of 1 mm and a radius of 1 mm, where (x, y, z) represents the coordinates of a point on the inner surface of the double free-form surface lens in the X-Y-Z three-dimensional space. Referring to Fig. 2(1), the target surface is a circular surface with a radius of 100mm, divided according to Fig. 2(1), N is 200, M is 300, and the distance from the light source to the target surface is 50mm. Referring to FIG. 5(2), it is a diagram of the illuminance distribution of the double free-form surface lens on the targe...

example 2

[0048] Referring to FIG. 6(1), this embodiment relates to a rotationally symmetrical double free-form surface lens whose outer surface is cylindrical and whose inner surface is a free-form surface. The material of double freeform surface lens is PMMA (polymethyl methacrylate) in the present embodiment, and inner surface height is 2 millimeters, and outer surface height is 4 millimeters, and the function relation of given outer surface is 4=x 2 +y2 (0≤z≤4), that is, a cylinder with a height of 4 mm and a radius of 2 mm, where (x, y, z) represents the coordinates of a point on the outer surface of the double free-form surface lens in the X-Y-Z three-dimensional space. Referring to Fig. 2(1), the target surface is a circular surface with a radius of 200mm, divided according to Fig. 2(1), N is 500, M is 800, and the distance from the light source to the target surface is 100mm. Referring to FIG. 6(2), it is a diagram of the illuminance distribution of the double free-form surface ...

example 3

[0050] Referring to FIG. 7(1), this embodiment relates to a rotationally symmetrical double free-form surface lens whose inner surface is hemispherical and outer surface is a free-form surface. The material of double free-form surface lens is PP (polymethyl methacrylate) in the present embodiment, and inner surface height is 1 millimeter, and outer surface height is 3 millimeters, and the function relation of given inner surface is z=(1-x 2 -y 2 ) 0.5 , which is a hemispherical surface with a radius of 1 mm, where (x, y, z) represents the coordinates of a point on the inner surface of the double free-form surface lens in the X-Y-Z three-dimensional space. Referring to Fig. 2(1), the target surface is a circular surface with a radius of 100mm, divided according to Fig. 2(1), N is 500, M is 500, and the distance from the light source to the target surface is 50mm. Referring to FIG. 7(2), it is a diagram of the illuminance distribution of the double free-form surface lens on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com