Mechanical explosive-filling device and method for filling explosive by using same

A charging and explosive technology, which is applied in blasting and other directions, can solve the problem that horizontal holes cannot quickly compact the charging, and achieve the effects of simple and convenient production, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

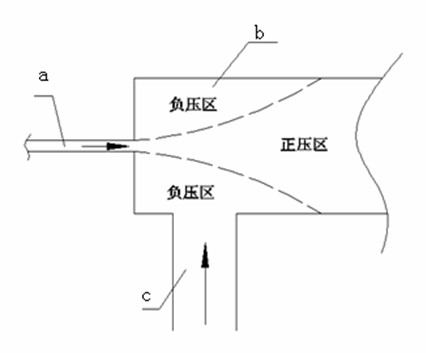

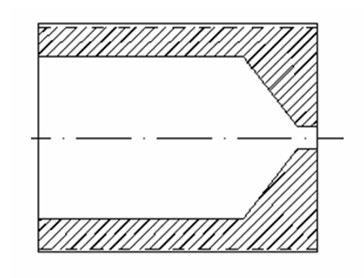

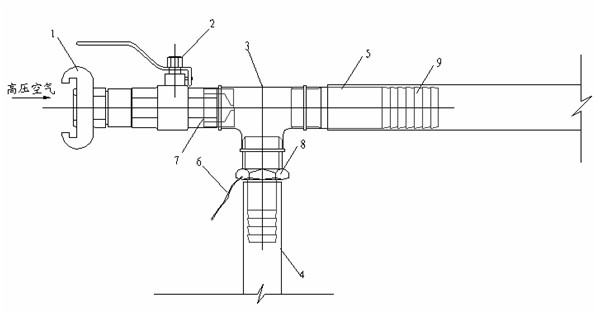

[0034] Such as figure 1 As shown, a kind of mechanized charging device proposed by the present invention includes a pressure air input port 1, a pressure air valve 2, and a three-way pipe 3 connected in sequence, and the pressure air valve 2 is connected with the first three-way pipe 3 in the horizontal direction. One end is connected, the end of the three-way pipe 3 perpendicular to the horizontal direction is connected to the first pagoda joint 8, the explosive input pipe 4 is connected to the first pagoda joint 8, the second end in the horizontal direction is connected to the second pagoda joint, and the explosive output pipe 5 is connected to The second pagoda connector; also includes an aperture element 7, such as figure 2 As shown, the small hole element 7 is in the shape of a cylinder, and one end has a large aperture, and the other end has a small aperture. Inside the compressed air valve, the end with a smaller aperture is matched and connected to the first end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com