Brushless DC motor vector control system and method based on alpha-beta current controller

A current controller, brushed DC motor technology, applied in vector control systems, control systems, control generators, etc., can solve the problem of the bootstrap capacitor being unable to be charged, to solve the difficulty of charging the bootstrap capacitor, reduce the commutation torque Torque ripple, effect of simplified control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

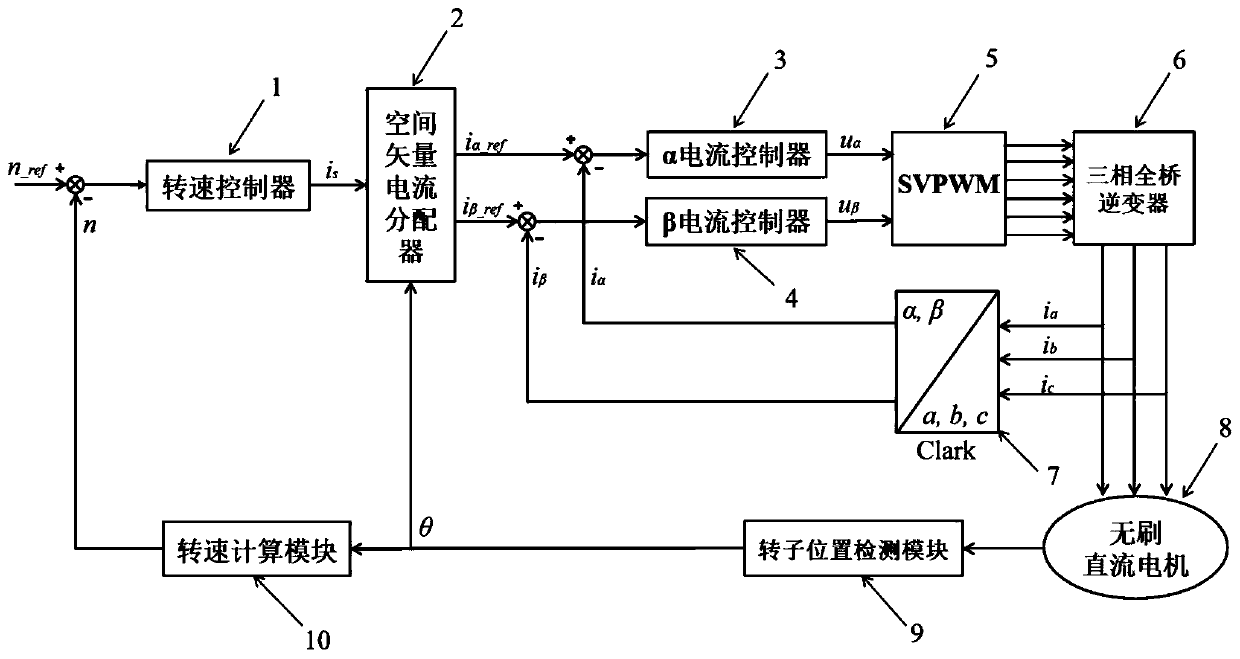

[0032] as attached figure 1 As shown, a brushless DC motor vector control system based on αβ current controller in this embodiment mainly includes the following modules: speed controller 1, space vector current distributor 2, α current controller 3, β current A controller 4 , an SVPWM module 5 , a three-phase full-bridge inverter 6 , a Clark converter 7 , a brushless DC motor 8 , a rotor position detection module 9 , and a rotational speed calculation module 10 . The rotor position detection module 9 uses a Hall position sensor. Speed controller 1, α current controller 3, and β current controller 4 use PID controllers.

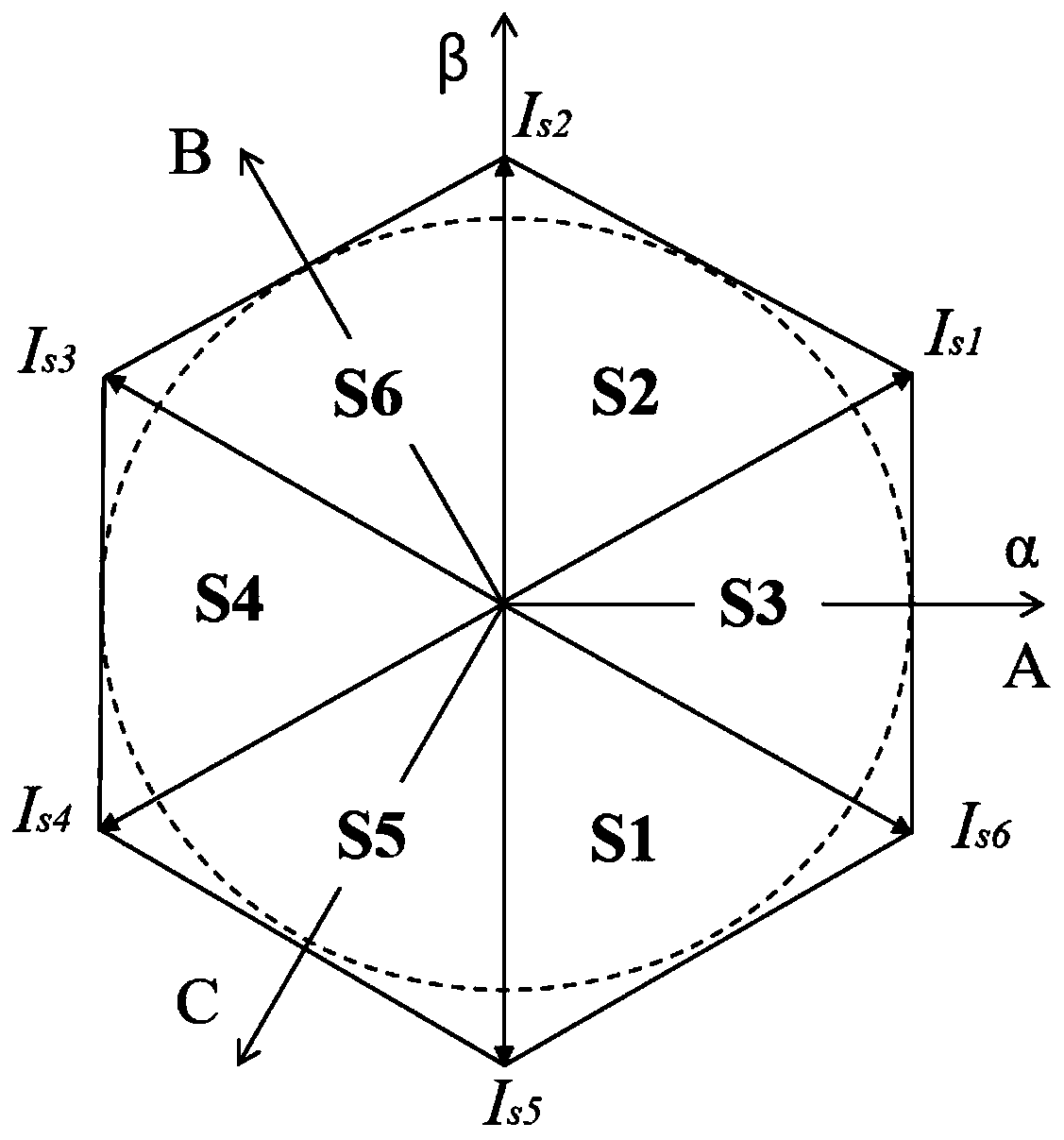

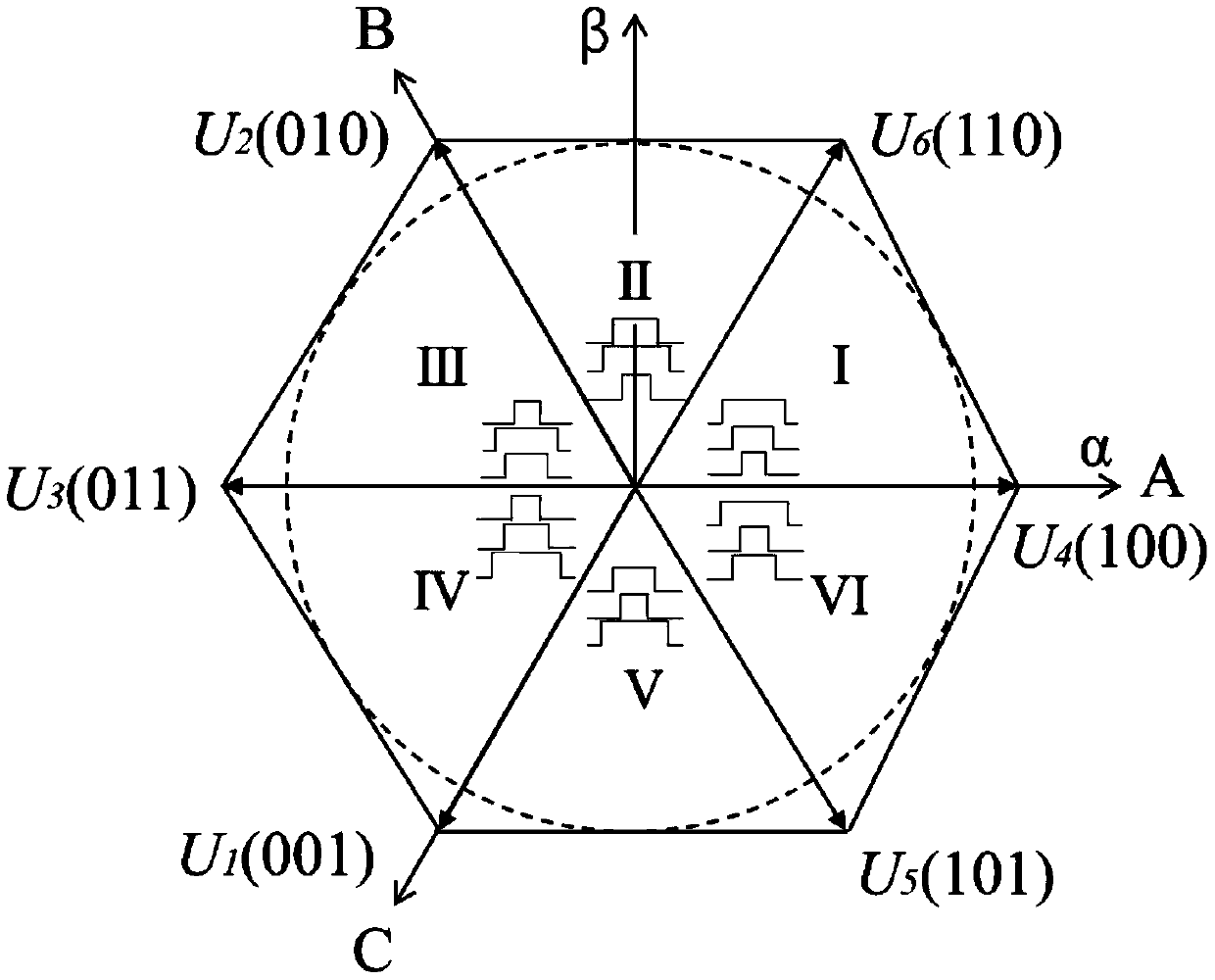

[0033] The principle of field-oriented space vector control in this embodiment is as follows:

[0034] When the back electromotive force of the motor is a sine wave, it is driven by a sine wave current, and the electromagnetic torque fluctuation of the motor is the smallest. The space vector current driven by a sine wave has a continuous rotation angle, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com