Electric vehicle battery box temperature control system

A temperature control system, electric vehicle technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of reducing the cruising range of electric vehicles, increasing battery energy consumption, etc., to solve the sharp decline in performance, prolong service life, improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

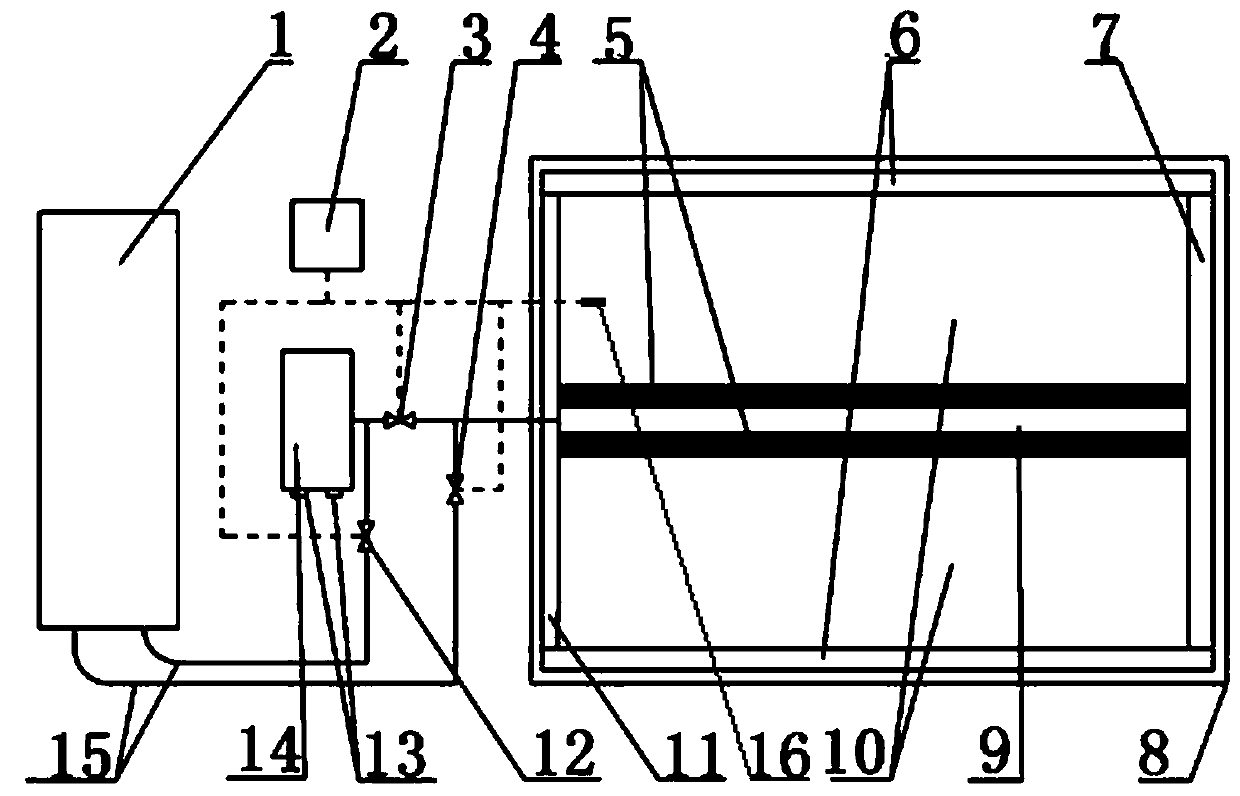

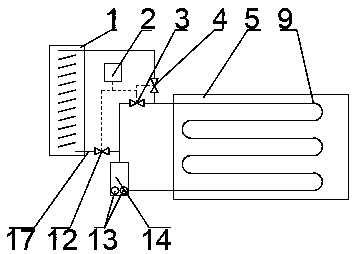

[0013] A temperature control system for a battery box of an electric vehicle, comprising a finned tube heat exchanger 1, an air bubble pump 14, a control module 2, a solenoid valve A3, a solenoid valve B4, a solenoid valve C12, a control module 2, a heater 13, and a temperature sensor 16 and the plate heat exchanger 9, the heat exchange medium circulating in the temperature control system of the battery box is refrigerant, the solenoid valve A3, solenoid valve B4, solenoid valve C12, heater 13 and temperature sensor 16 are electrically connected to the control module 2 through wires. Connection, the heater 13 is connected with the air bubble pump 14 to heat the refrigerant in the air bubble pump 14, and the temperature sensor 16 detects the real-time temperature of the battery pack 10 in the battery box 8, and the temperature sensor 16 is arranged in the battery box, preferably attached to On the surface of the battery pack 10, a plate heat exchanger 9 is provided between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com