High-frequency anti-water-leakage satellite vibration test clamp for large interface expanding

A test fixture and interface expansion technology, applied in the field of vibration test fixtures, can solve problems such as reducing height and increasing frequency, and achieve the effects of increasing frequency, reducing height, and improving work efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

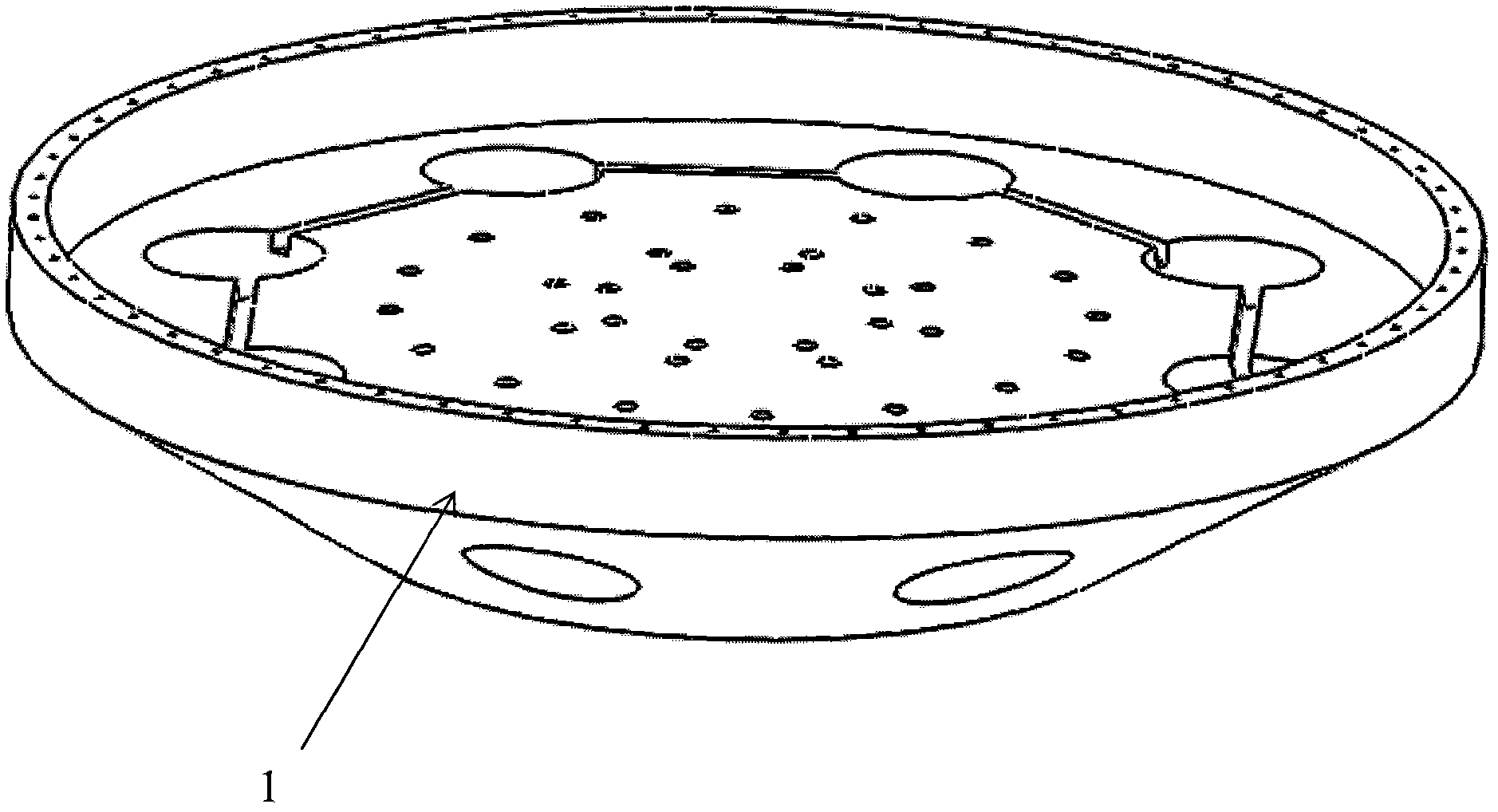

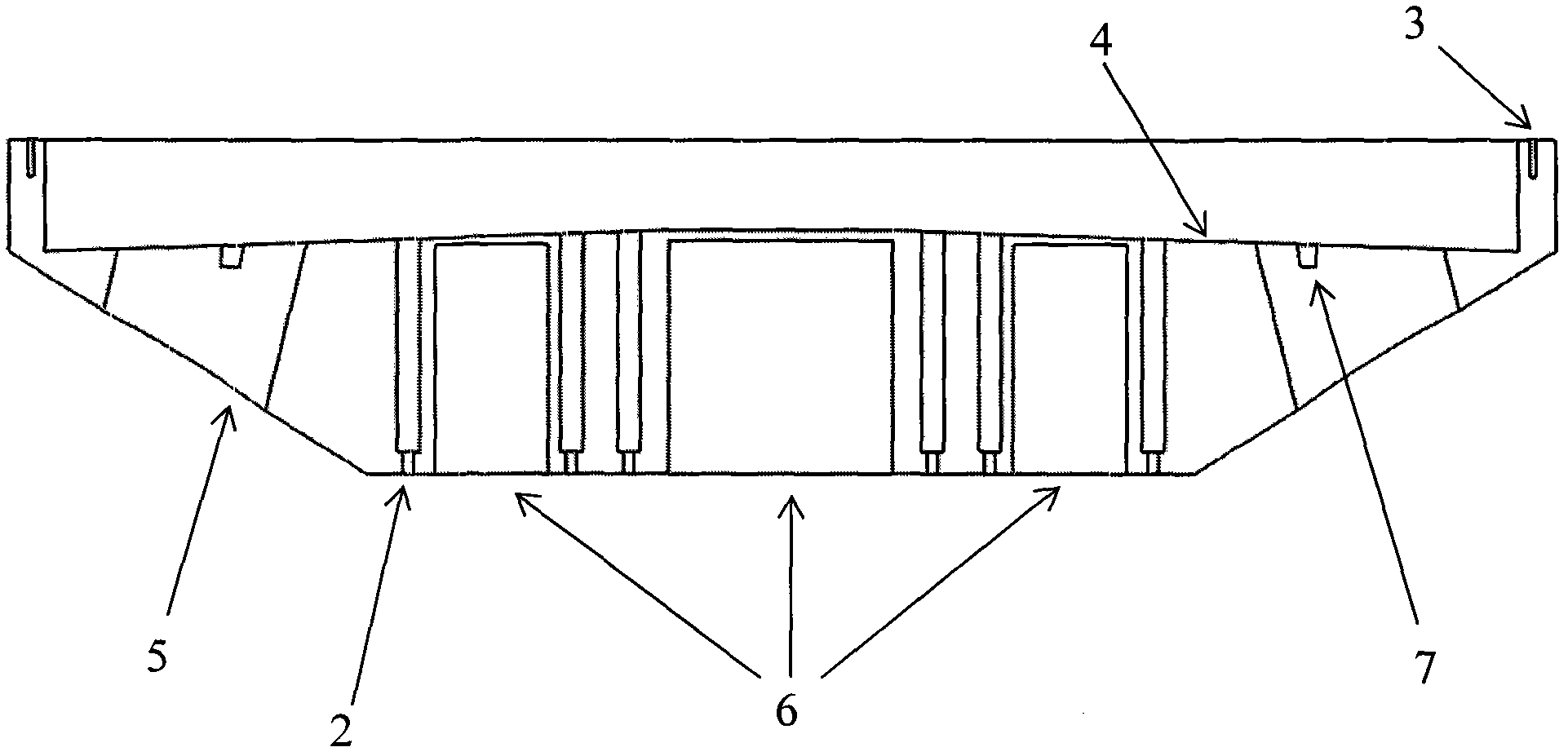

[0014] see figure 1 and figure 2 , the satellite vibration test fixture of the high-frequency water-leakage-proof satellite vibration test fixture that the large interface expands of the present invention is to add the solid circular platform of lightening hole, and the diameter of its upper circular platform is phi 2100mm, and the diameter of the lower circular platform is φ 990mm, at the bottom of the circular platform toward the described circle A circular groove is arranged inside the shape, and the bottom of the circular groove is the top slope 4 of the clamp, and 8 edge slope lightening holes 5 are opened on the slope of the circular table on the top slope, and the multiple edge slopes The lightening holes are evenly distributed along the circumferential direction on the top slope, and the edge lightening holes are oblique through holes of φ250mm, which are inclined to the outside of the fixture. One end opening is located on the top slope 4, and the other end opening i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com