Method for testing elastic modulus and strength of fiber materials and device thereof

An elastic modulus, fiber material technology, applied in the field of material performance testing, can solve the problems of insufficient load resolution, difficult elongation testing, difficult testing, etc., to achieve the effect of simplifying the testing process and realizing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

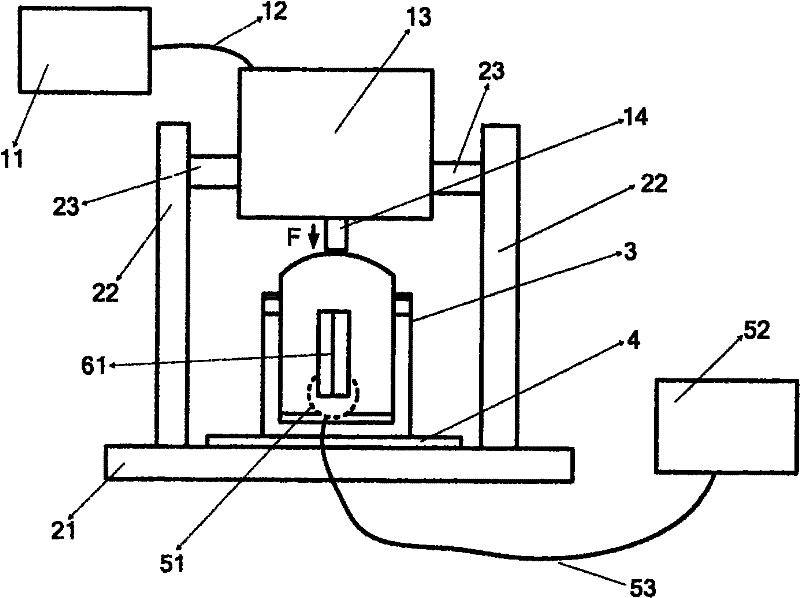

[0104] Embodiment: Measuring the elastic modulus and strength of platinum-silver alloy filaments

[0105] The specific operation process is:

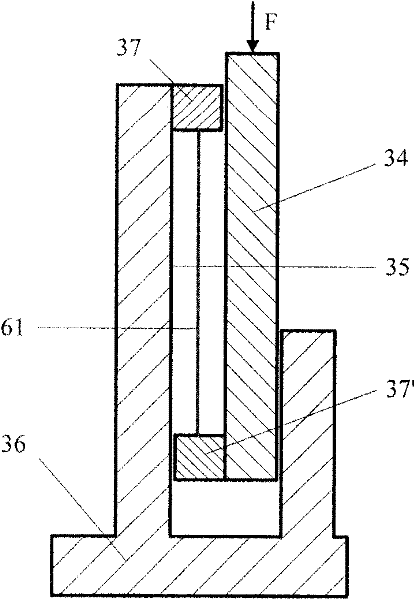

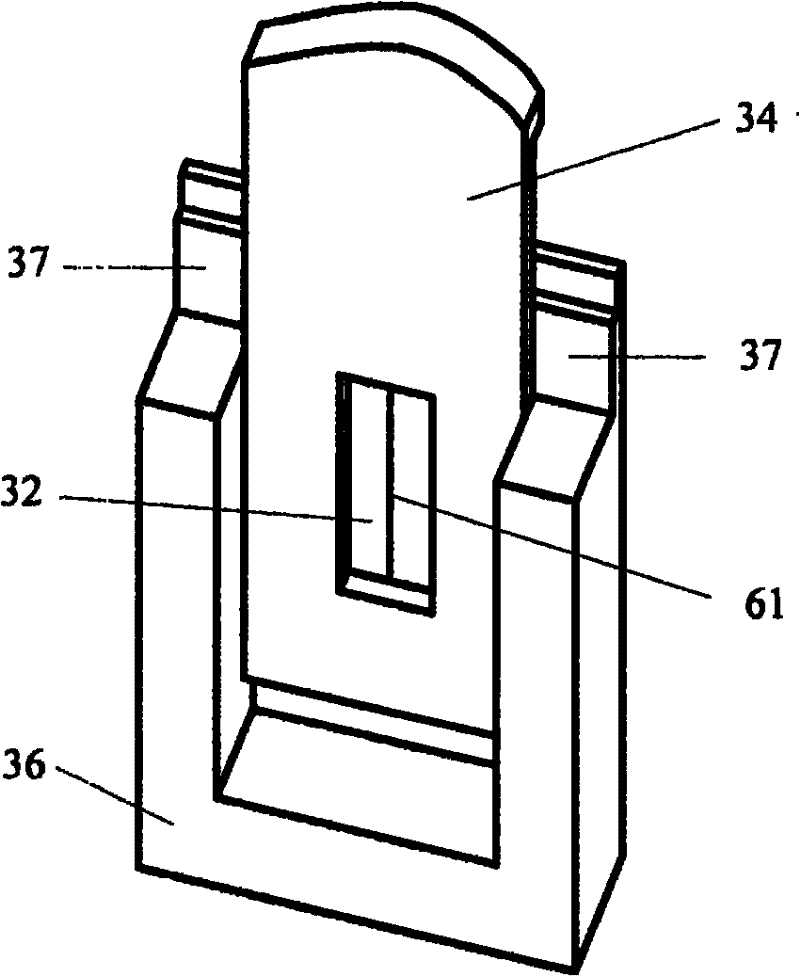

[0106] 1) Platinum-silver alloy filaments were selected as the experimental samples, and the cross-sectional area of the filaments was measured with a VHX-600E precision microscope produced by KEYENCE in Japan S=0.0075mm×0.075mm. Mass of slider with observation hole m 0 =42.8g, stick a grid on the inner wall of the base of the fixture as a reference coordinate (the side length of each square grid is 2.5mm);

[0107]2) Stick two marking strips on the filament with 502 glue, and fix each end of the filament with two triangular plastic blocks with 502 glue; carefully place the bonded filament on the upper and lower sides of the vertical direction of the fixture. place the slider carefully in the base of the fixture, the self-weight of the slider makes the filament stretch under the initial load (42.8 / 1000×9.8=0.42N) between the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com