Alloy solidification synchrotron radiation imaging visualization method

An imaging and alloying technology, which is applied in the use of radiation for material analysis, preparation of test samples, etc., can solve problems such as low heating temperature, limited application range and research field, so as to improve the mechanical and physical properties and improve the microscopic growth of alloys , Optimize the effect of solidification structure control engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

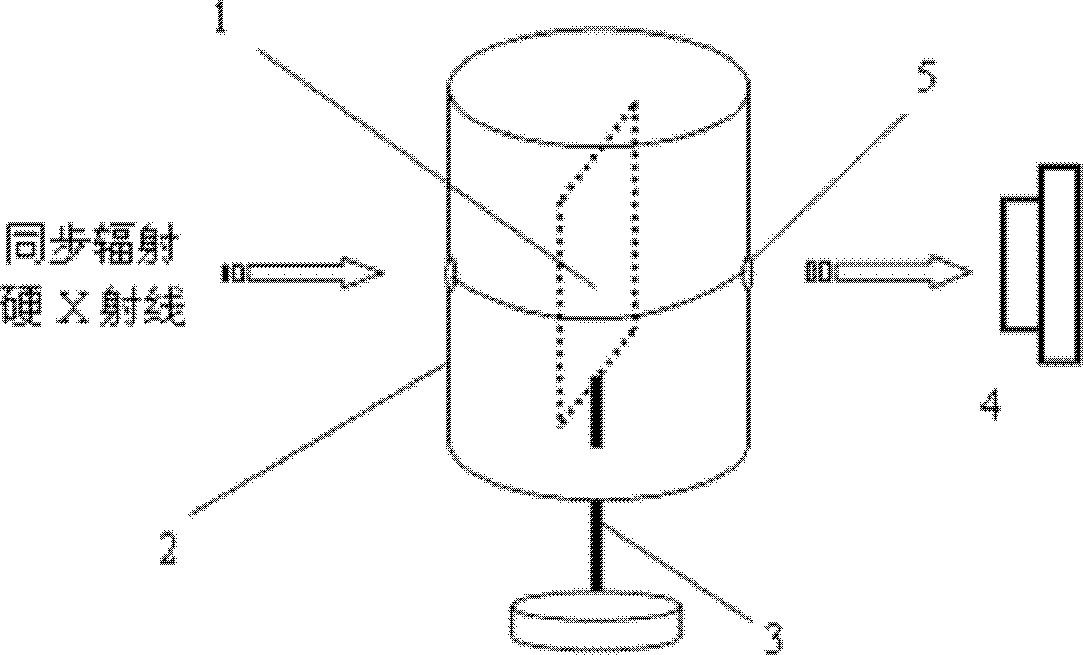

[0043] A method for visualization of alloy solidification synchrotron radiation imaging, comprising the following steps:

[0044] 1. Sample Preparation

[0045] (1) Preliminary sample preparation

[0046] a. Use a vacuum melting furnace to prepare an alloy with a certain composition, and pour it into a water-cooled copper mold to obtain an ingot;

[0047] b. The ingot sample is cut transversely into 1mm slices;

[0048] c. Use 502 glue to stick the thin slice sample on the stainless steel sample holder, and grind the front and back of the sample with 200#, 400#, 600#, 800# sandpaper, and finally make an ultra-thin sample with a thickness of 100-200μm;

[0049] d. Soak the sample with acetone solution to make the ultra-thin sample fall off the sample holder automatically, and perform ultrasonic cleaning in the acetone solution;

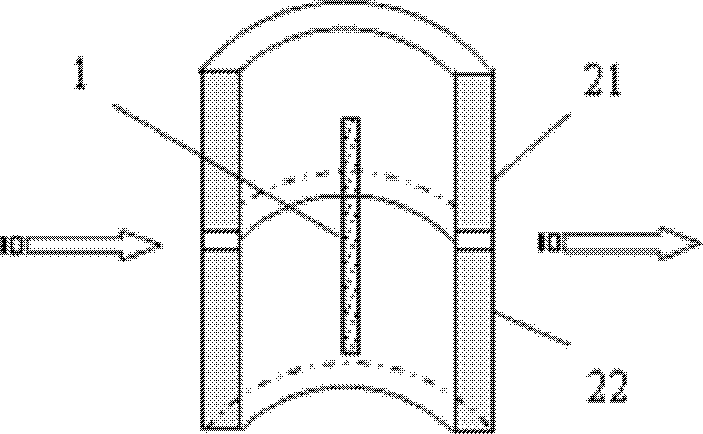

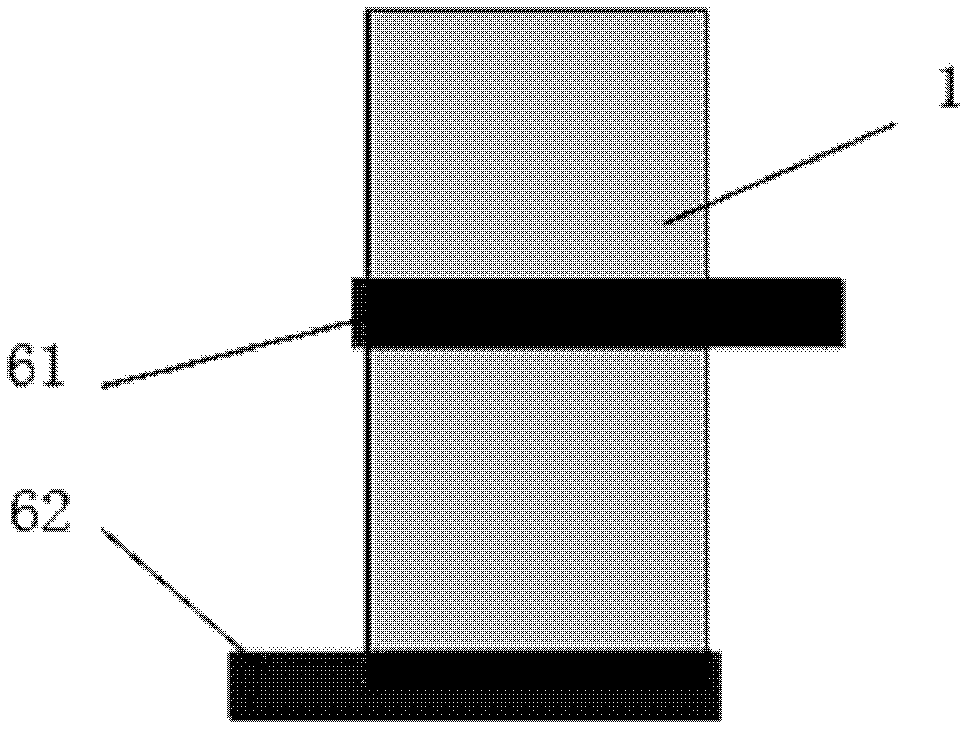

[0050] e. Cut the ultra-thin sample into 20×10mm 2 , and placed in the middle of a hollow mica sheet with a thickness of 100 μm, and then sandwich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com