Automatic ageing and testing device and method

A test device and automatic technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of limited production capacity, no enterprise, low efficiency, etc., achieve stable product quality, high degree of automation, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

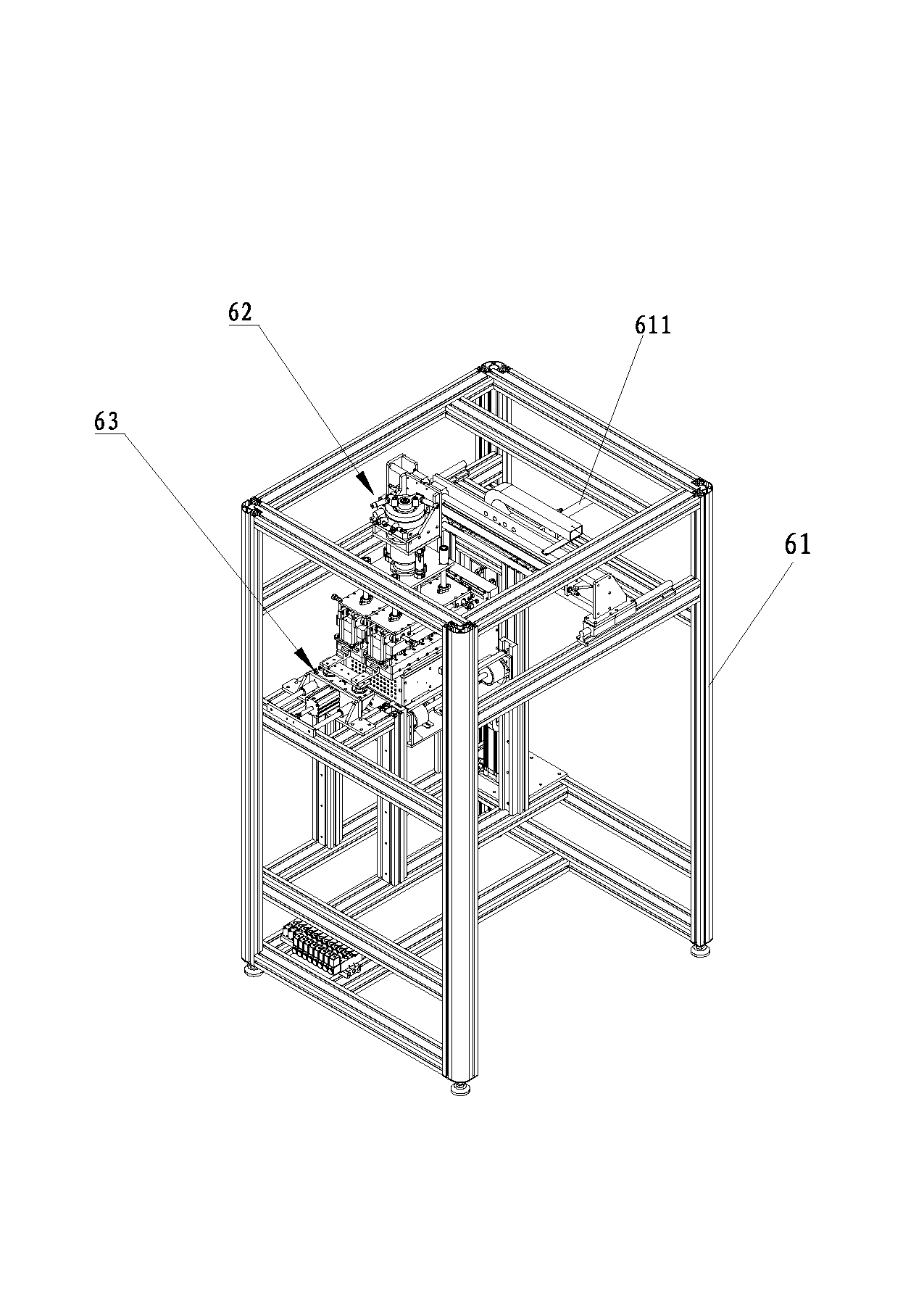

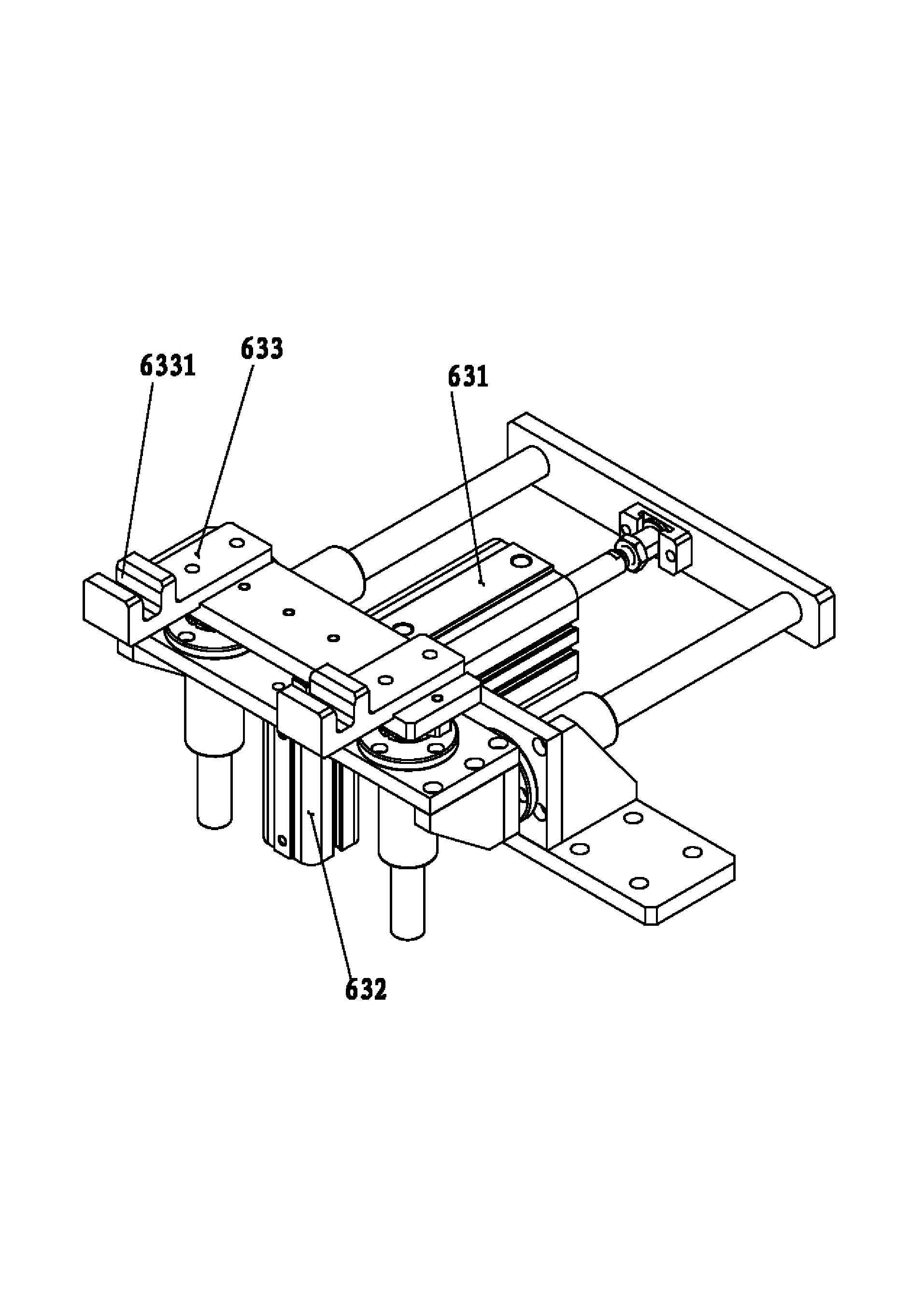

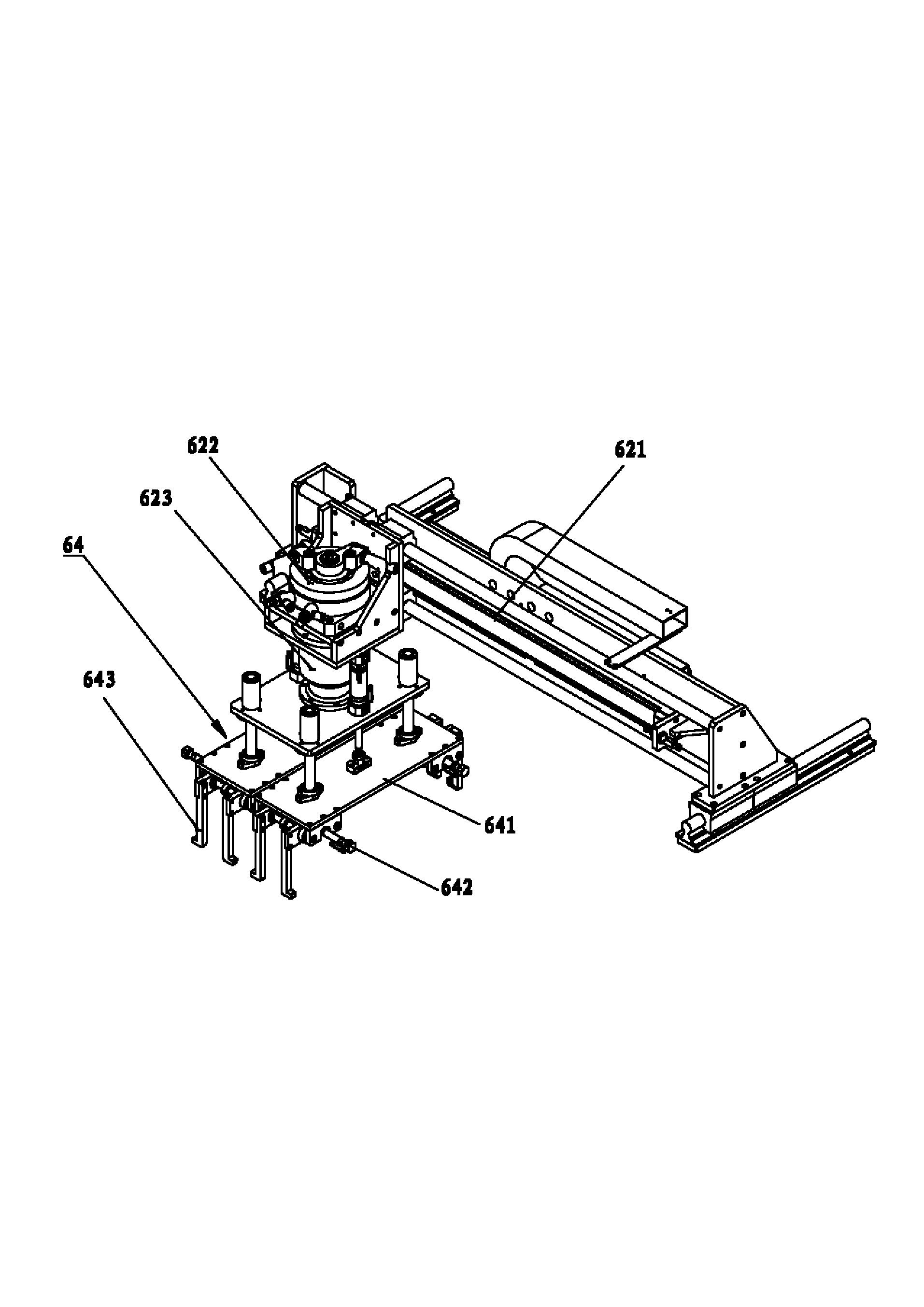

[0069] Embodiment 1 of an automatic aging and testing device of the present invention is as Figure 1 to Figure 12 As shown, it includes a frame 1, a child fixture 2 and a mother fixture 4 that can be used in conjunction with each other, an aging mechanism 3 and a testing mechanism 5 that are respectively arranged on the frame 1, and separate the child fixture 2 and the mother fixture 4. The separating mechanism 6 and the control device capable of controlling the separating mechanism 6 , the aging mechanism 3 and the testing mechanism 5 .

[0070] When working, the electronic product 10 is loaded into the sub-fixture 2 at the upper machine position, and then the sub-fixture 2 and the mother jig 4 are combined at the sub-mother jig assembly station and then transported to the aging mechanism 3 for automatic aging. After the completion, the child fixture 2 and the mother fixture 4 are transported to the separation mechanism 6, and the separation mechanism 6 separates the child f...

Embodiment 2

[0081] A kind of automatic aging and testing device of this embodiment can be found in Figure 5 to Figure 9 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0082] refer to Figure 6 and Figure 7 , the sub-fixture 2 includes a base 21 and an upper cover 22 arranged above the base 21, the base 21 is provided with a base PCB, the base PCB is provided with a sub-fixture DC signal connection device 211, the base 21 is opposite to the upper cover 22 A product placement slot 213 is provided on the inner surface for placing the electronic product 10, and a DC signal interface 212 is provided in the product placement slot 213, and the DC signal interface 212 is electrically connected to the DC signal connection device 211 of the sub-fixture through the base PCB board;

[0083] refer to Figure 8 , the upper cover 22 is ...

Embodiment 3

[0094] A kind of automatic aging and testing device of this embodiment can be found in Figure 10 and Figure 11 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0095] refer to Figure 10 , the automatic aging and testing device also includes a translation mechanism 7 for transporting the child fixture 2 and the mother fixture 4 to the aging mechanism 3 or the testing mechanism 5, the translation mechanism 7 includes a burn-in terminal and a test terminal, and the burn-in terminal and the burn-in mechanism 3 is connected to the input end, and the test end is connected to the input end of the test mechanism 5, so as to realize the transition between the aging process and the test process of the child fixture 2 and the mother fixture 4.

[0096] refer to Figure 11 The translation mechanism 7 includes a translation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com