Thermotechnical electrical integrated control system for thermal power plant

An electrical and power plant technology, applied in the field of power system, can solve the problems of impossible to achieve digital remote control, high reliability power plants, etc., to achieve the effect of improving fault self-checking ability, improving work efficiency, and reducing the types of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and through specific embodiments.

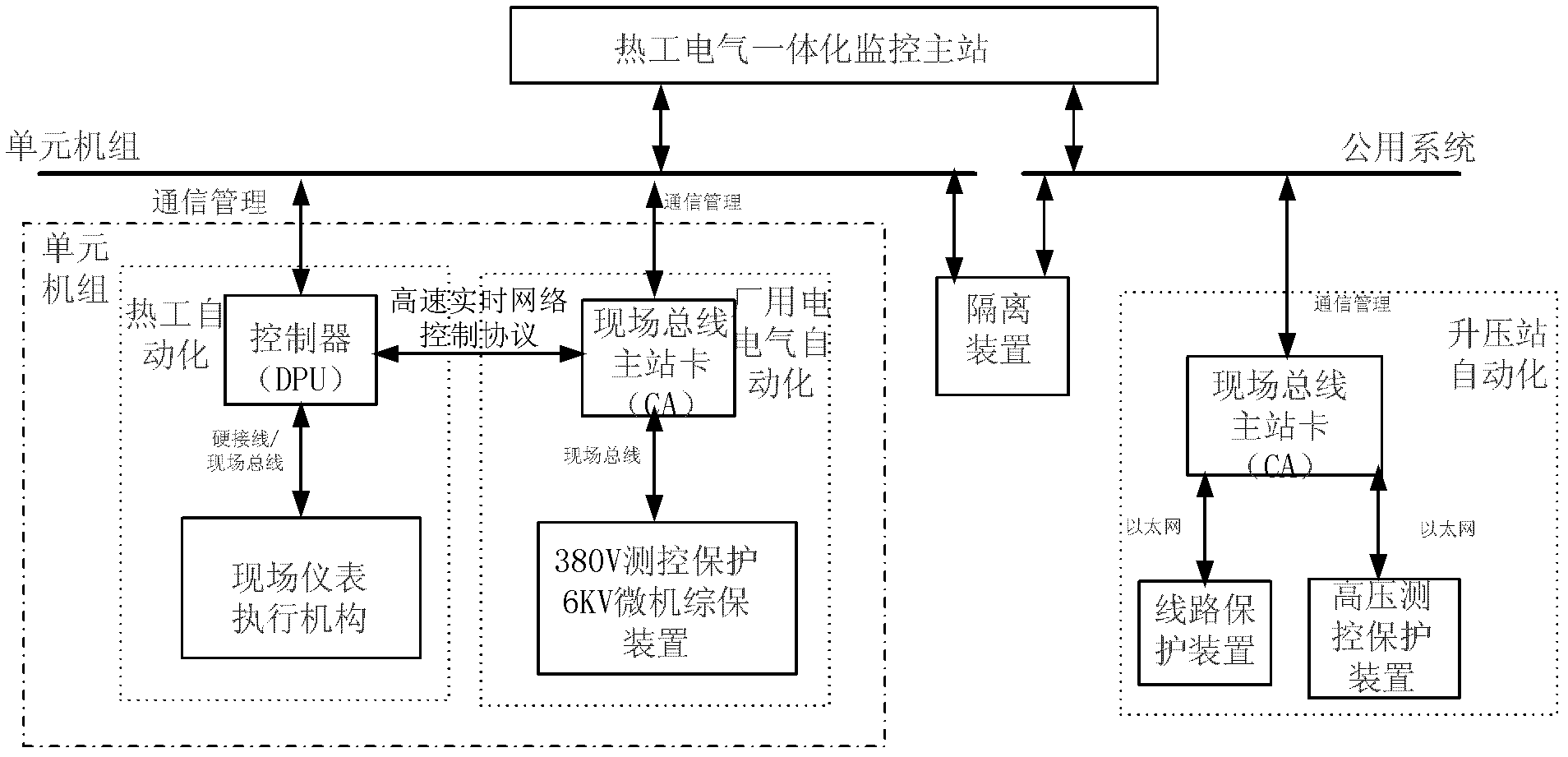

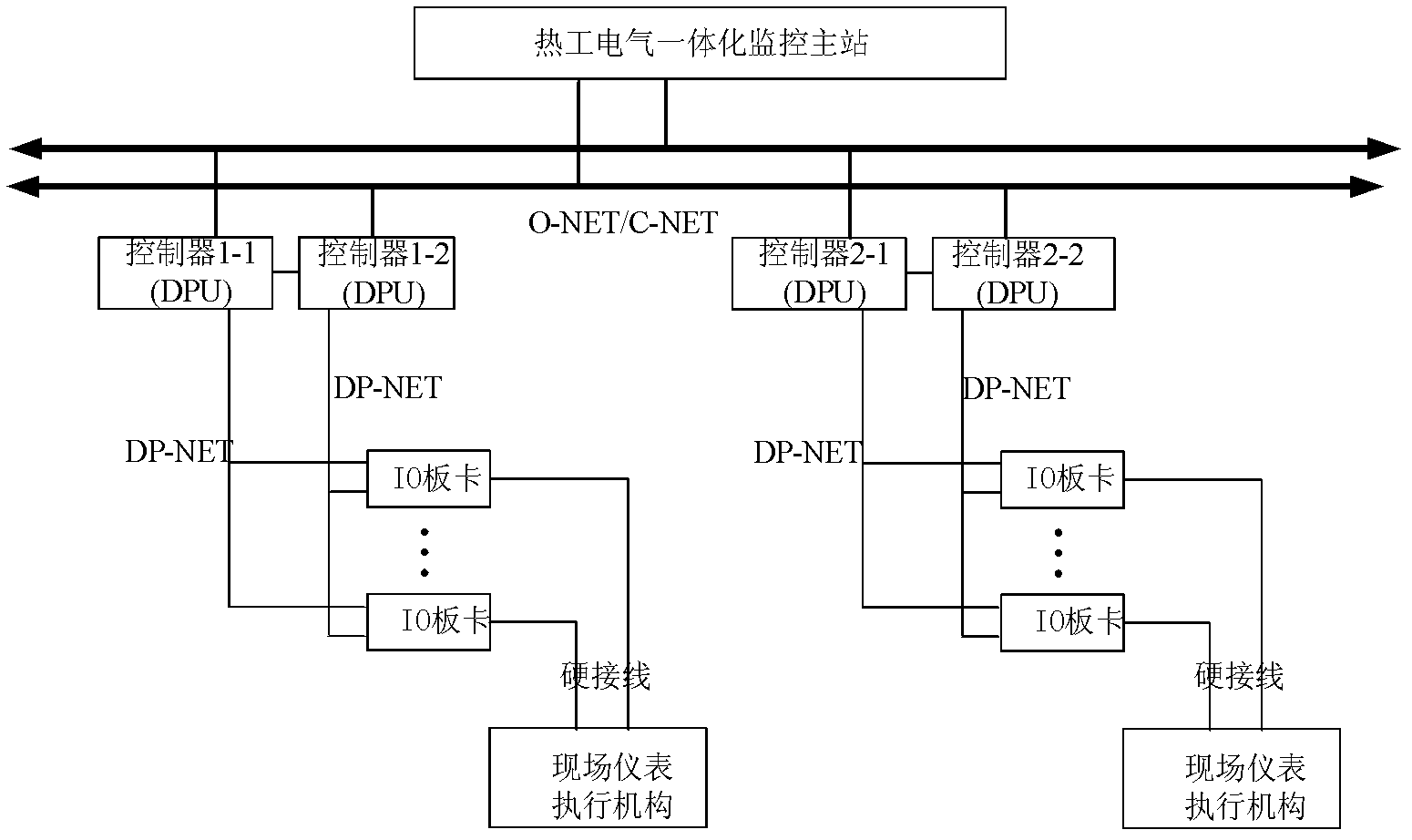

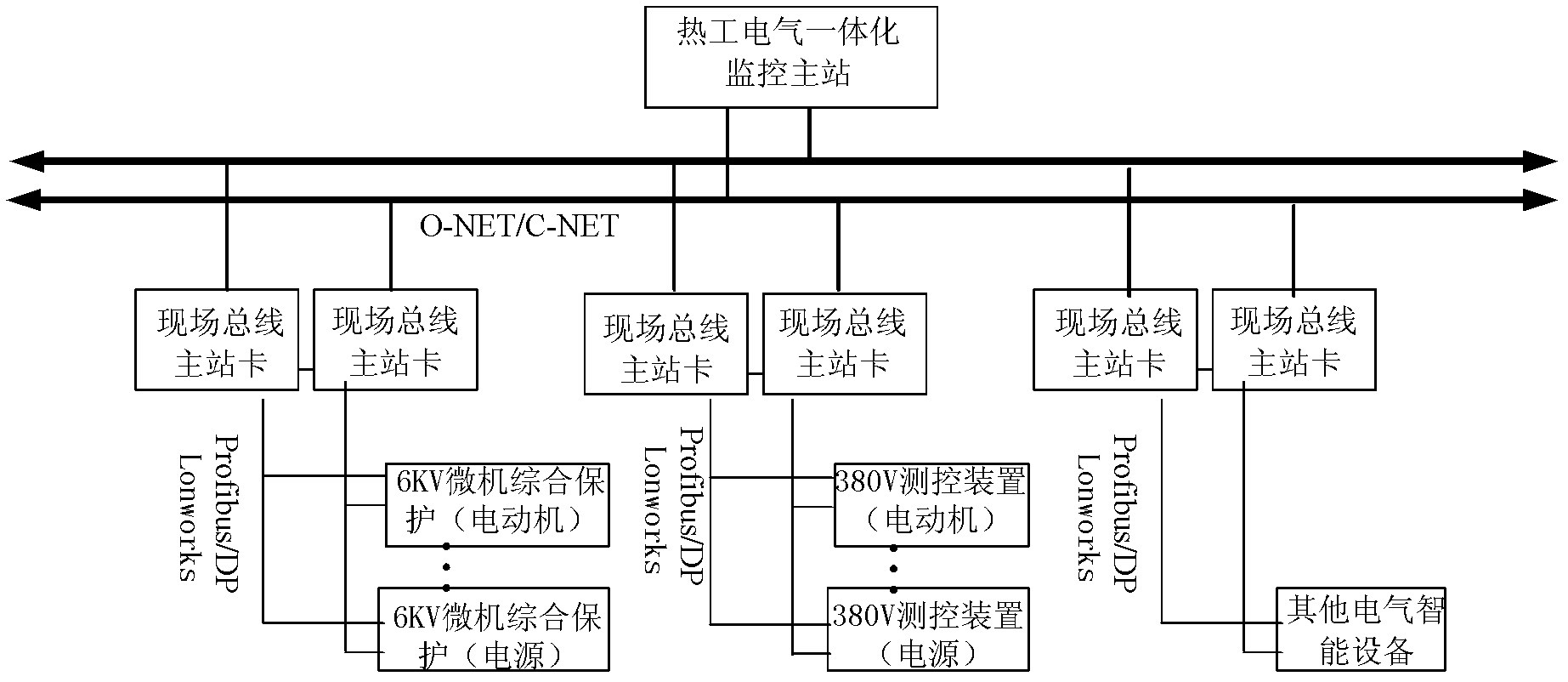

[0024] figure 1 It is a schematic diagram of the structure of the thermal-technical-electrical integration control system in a power plant. It mainly includes monitoring master station, unit unit and public system. The unit unit is composed of a thermal automation system and a plant electrical automation system, and the public system is composed of a booster station automation system. The server of the monitoring master station is connected to both the distributed processing unit (ie controller DPU) and the public system through the monitoring layer network (Ethernet) to form the real-time information backbone network of the system, which is responsible for the data information between the distributed processing units. Collection and management; an isolation device is set between the unit unit and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com