Disc label surface contrast compensation method

A compensation method and contrast technology, applied in the direction of instruments, packaging, record carrier accessories, etc., can solve the problems that the laser power cannot be increased, the label cannot be clearly identified, and the reading head is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to achieve the above object, the present invention adopts the technical means and its effects, the preferred embodiments are given, and are described as follows in conjunction with the drawings.

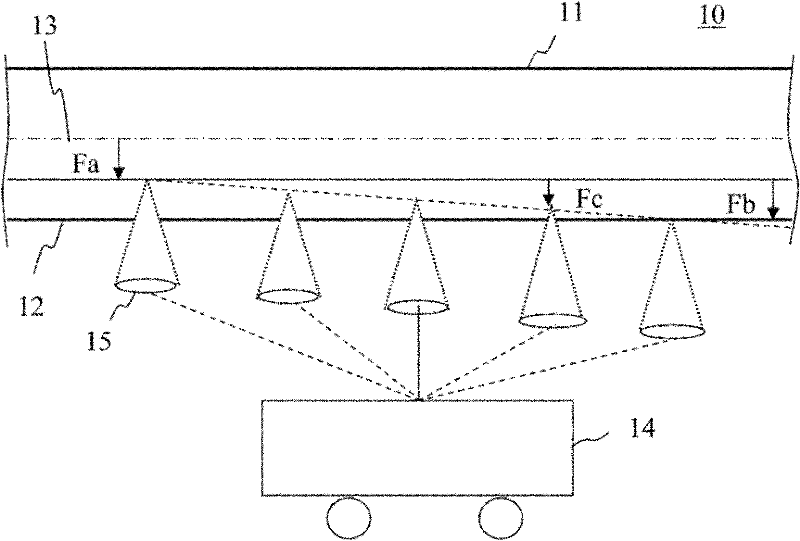

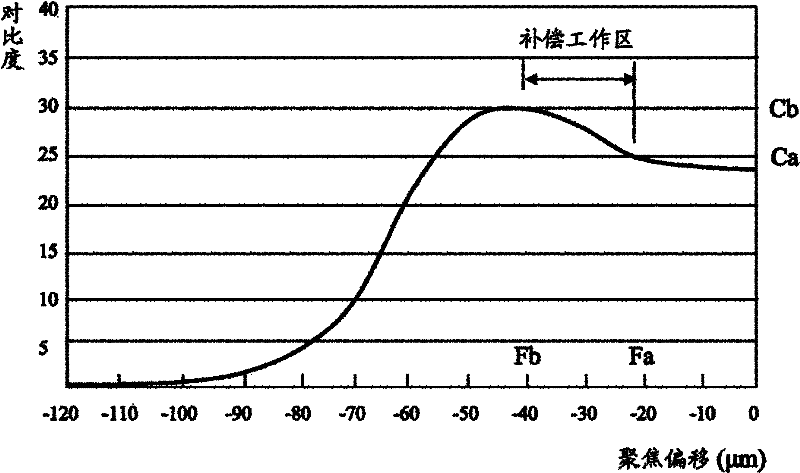

[0026] Please also refer to figure 2 and image 3 , figure 2 It is a schematic diagram of contrast compensation on the disc label surface of the present invention, image 3 It is a coordinate diagram of the contrast curve of the present invention. figure 2 When the optical drive 10 of the present invention burns a label on the label surface 12 of the optical disc 11, although the focus curve 13 is preset, it does not use the focus curve 13 to control the reading head 14 to move the objective lens 15 to focus, but to move the focus curve 13 by one A predetermined distance Fa is used to perform the so-called focus offset burning label, so as to obtain the target contrast and reserve a space for adjusting the focus.

[0027] The aforementioned method of determinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com