Zinc oxide lightning arrester and manufacturing method thereof

A lightning arrester and zinc oxide technology, which is applied in the manufacture of resistors, resistors, overvoltage protection resistors, etc., can solve the problems of waste in the electrical sector, damage to power distribution equipment, and short service life of lightning arresters, so as to prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

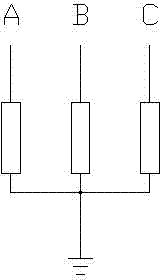

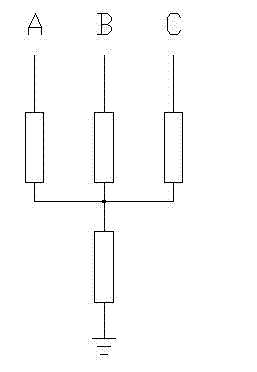

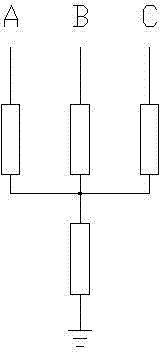

Image

Examples

Embodiment 1

[0021] Embodiment 1: (1), dry the resistor sheet with qualified tissue, the drying temperature is 80°C, and the drying time is 12 hours;

[0022] (2) Wrap the dried resistance sheet with a weft-free tape made of epoxy glass fiber;

[0023] (3) After putting the wound resistance sheet on the shelf to fix the height of the structure, bake it again. The temperature during baking is 120°C, and bake for 12 hours;

[0024] (4) After the resistor is cooled, test the leakage voltage value of the arrester under the condition of a DC current of 1mA;

[0025] (5) After drying the winding and passing the test, heat the arrester to 120°C, apply the coupling agent, and then perform high-temperature compression molding under the conditions of a pressure of 10MP and a temperature of 165°C. The film pressing time is 360″;

[0026] (6) The arrester that has been laminated is tested according to the detection standard of the arrester.

Embodiment 2

[0027] Embodiment 2: (1), dry the resistance sheet with qualified structure, the drying temperature is 100 ℃, and the drying time is 11 hours;

[0028] (2) Wrap the dried resistance sheet with a weft-free tape made of epoxy glass fiber;

[0029] (3) Put the wound resistance sheet on the shelf to fix the height of the structure, then bake again, the temperature during baking is 120°C, and bake for 15 hours;

[0030] (4) After the resistor is cooled, test the leakage voltage value of the arrester under the condition of a DC current of 1mA;

[0031] (5) After drying the winding and passing the test, heat the arrester to 120°C, apply the coupling agent, and then perform high-temperature compression molding at a pressure of 10MP and a temperature of 168°C. The film pressing time is 330″;

[0032] (6) The arrester that has been laminated is tested according to the detection standard of the arrester.

Embodiment 3

[0033] Embodiment 3: (1), dry the resistive sheet with qualified tissue, the drying temperature is 120 ℃, and the drying time is 10 hours;

[0034] (2) Wrap the dried resistance sheet with a weft-free tape made of epoxy glass fiber;

[0035] (3) Put the wound resistance sheet on the shelf to fix the height of the structure, then bake again, the temperature during baking is 120°C, and bake for 18 hours;

[0036] (4) After the resistor is cooled, test the leakage voltage value of the arrester under the condition of a DC current of 1mA;

[0037] (5) After drying the winding and passing the test, heat the arrester to 120°C, apply the coupling agent, and then perform high-temperature compression molding under the conditions of a pressure of 10MP and a temperature of 170°C. The film pressing time is 300″;

[0038] (6) The arrester that has been laminated is tested according to the detection standard of the arrester.

[0039] The testing items include DC reference voltage test, sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com