QFP (Quad Flat Package) grounding welding plate

A grounding pad and matrix technology, applied in the field of QFP packaging, can solve the problems of grounding tin overflow, affecting conductivity, insufficient tin amount of grounding pad, etc., and achieve the effect of meeting grounding requirements and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

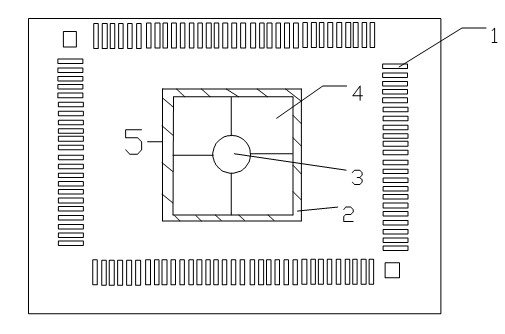

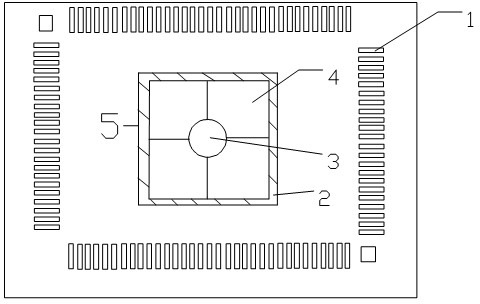

[0011] figure 1 This is a preferred embodiment of the present invention. The present invention will be further described below with reference to the accompanying drawings. Among them, 1 pin, 2 around the ground pad, 3 heat dissipation holes, 4 array holes, and 5 ground pads.

[0012] according to figure 1 , QFP grounding pad, characterized in that it includes a heat dissipation hole 3 located in the center of the grounding pad 5, a matrix arrangement hole 4 located on the grounding pad 5 and bypassing the heat dissipation hole 3; the thickness of the surrounding 2 of the grounding pad It is greater than the thickness of the middle of the ground pad 5; the four holes in the matrix arrangement are filled with solder paste. There are multiple pins 1 on the PCB board.

[0013] The aforementioned middle part of the QFP grounding pad 5 refers to the part of the grounding pad 5 excluding the periphery 2 of the grounding pad, and the thickness of the middle of the grounding pad 5 is 0.15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com