Eddy current inspection of case hardening depth

A hardening depth, eddy current technology, applied in the field of detection systems, can solve problems such as unsuitable surface hardening depth, not local information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present disclosure are described herein with reference to the accompanying drawings. In the ensuing description, well-known functions or constructions are not described in detail in order to obscure the understanding of the present disclosure with unnecessary detail.

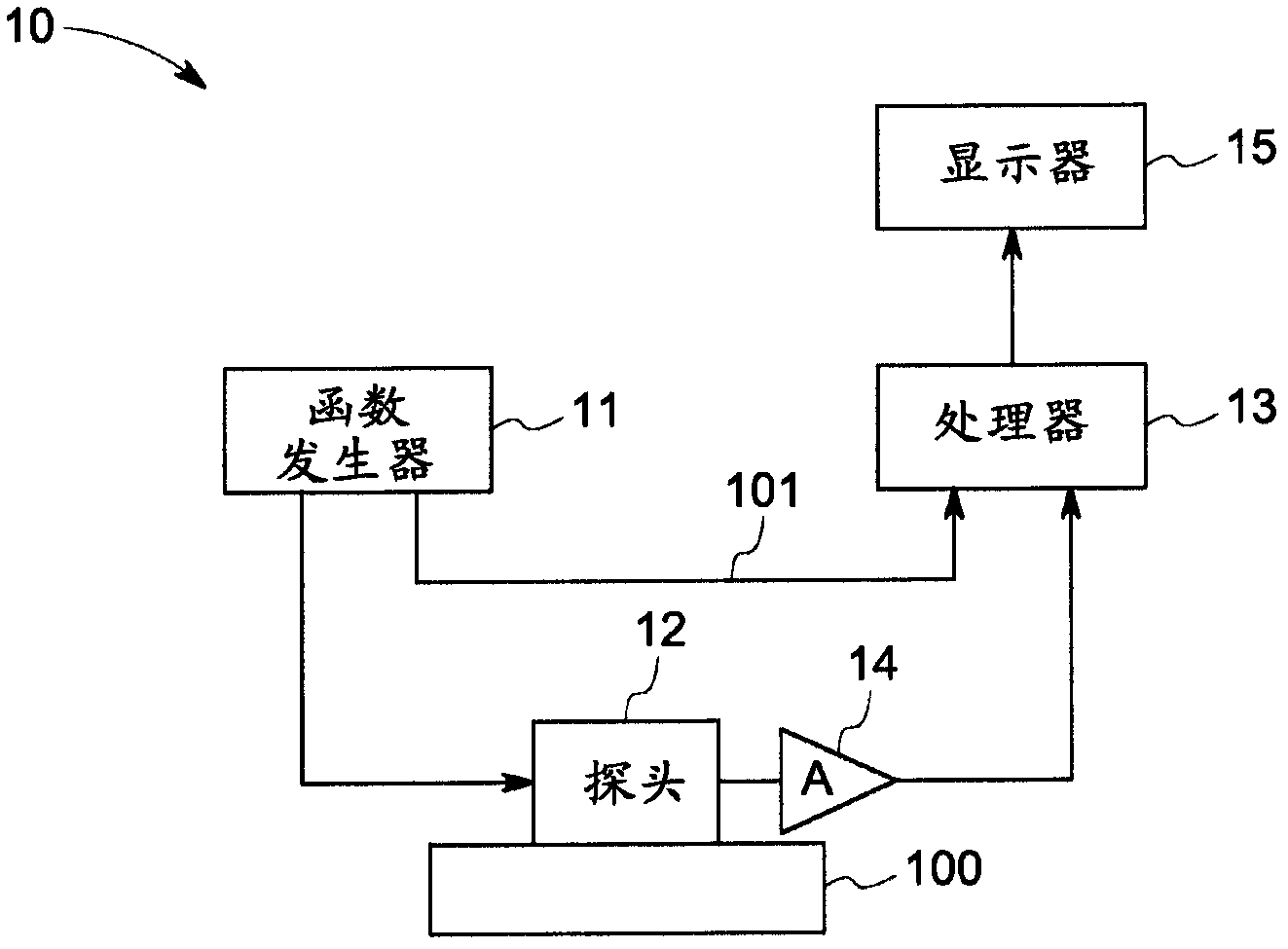

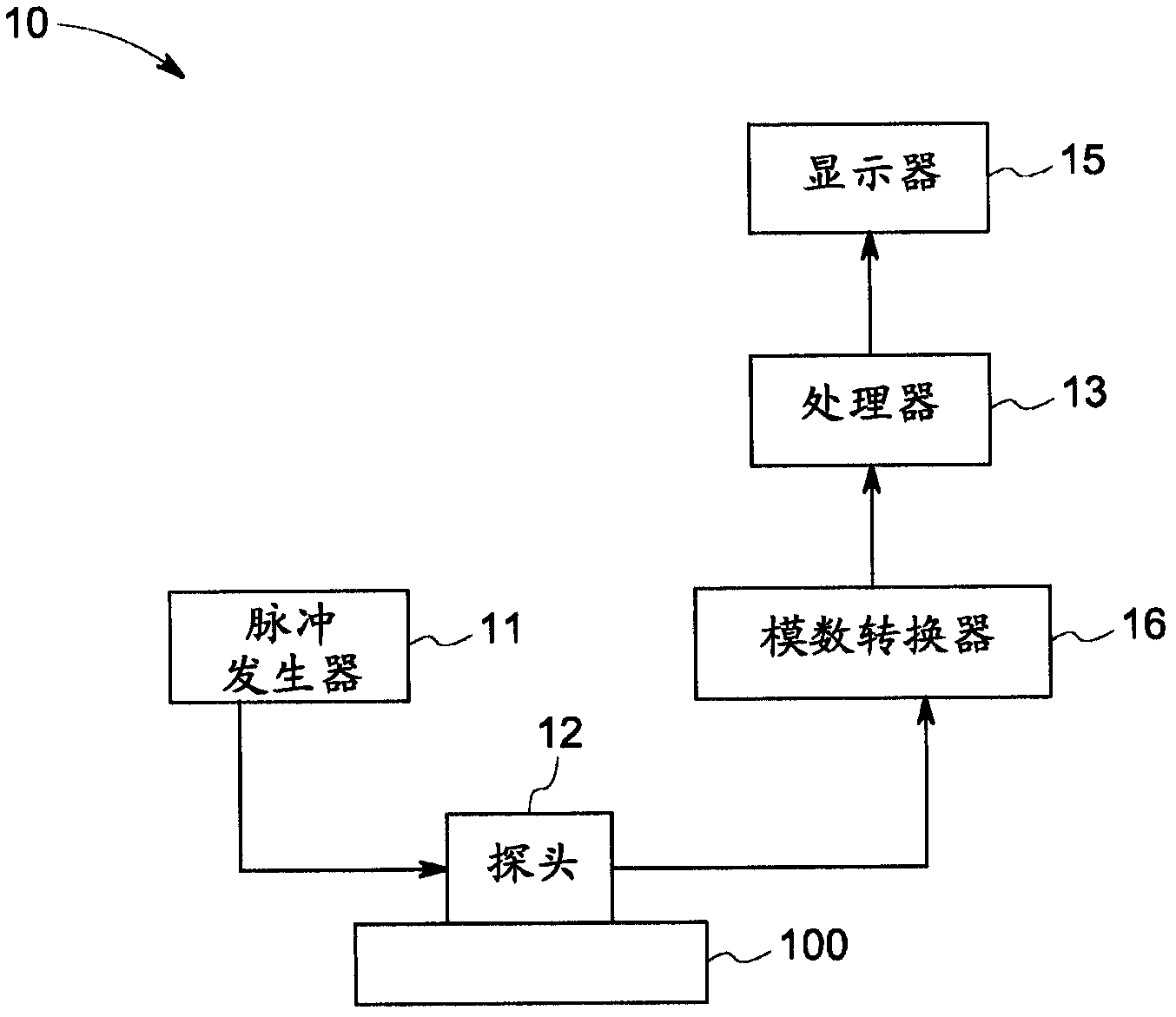

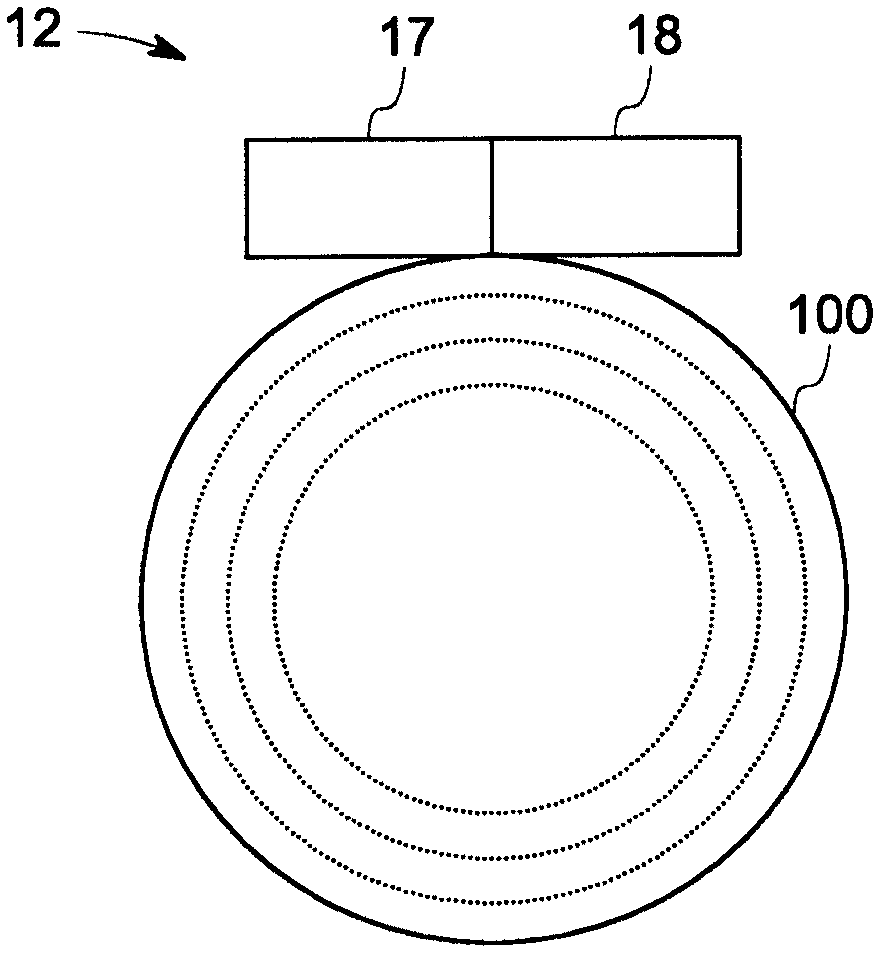

[0017] figure 1 is a schematic diagram of an eddy current inspection system 10 for inspecting a part 100 in accordance with one embodiment of the present invention. As used herein, the term "part" may refer to any object suitable for inspection, including but not limited to products, components, structures, test specimens, and the like. In some applications, the part 100 may be subjected to one or more hardening processes, such as a heat treatment process and a carburizing process, such that one or more hardened layers may form on the surface layer(s) of the part 100, thereby improving its abrasion resistance. For some arrangements, part 100 includes a cylindrical shape. In other ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com