Method for inspecting corrosion under insulation

A technology of insulating layer and rms value, which is applied in the field of corrosion under the insulating layer in inspection equipment, can solve problems such as poor efficiency and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0092] The insulating layer was removed from the air oxidation reactor (3.8 m in inner diameter) in which the liquid moved, and 4 FOD sensors (ch1 to ch4) were attached at intervals of 90° in the circumferential direction. The coating on the outer surface was removed with sandpaper, the FOD sensor was attached to the outer surface using a heat resistant epoxy based adhesive, and the FOD sensor was secured with aluminum tape attached to the FOD sensor.

[0093] Corrosion with an area of about 320 mm x about 90 mm and a depth of about 0.3 mm to about 0.5 mm was found at about 2.5 m above the FOD sensor ch1. No corrosion was found within 4m from the FOD sensor ch2. Corrosion with an area of about 350 mm x about 65 mm and a depth of about 0.3 mm to about 1.0 mm was found at about 2.5 m above the FOD sensor ch3, and at a position about 2 m from the lower right of the FOD sensor ch3 with an area of Corrosion of about 720mm by about 110mm, with a depth of about 0.3mm to 0.6mm. ...

example 2

[0108] Such as Figure 9 A model piping system was prepared as shown.

[0109] An insulating layer 13 was attached to a carbon steel pipe 10 having a total length of 5 m, and silicon oil heated by a heater 12 was circulated in the pipe 10 . In addition, corrosion is artificially accelerated in order to efficiently produce CUI. Specifically, pure water is continuously dripped from the dripping device 11 to the surface of the pipe 10, and the amount of the dripping liquid is finely adjusted to alternately produce a wet state and a dry state. Besides, common salt is coated on the surface of the pipe 10 . In addition, the silicone oil circulating through the pipe 10 is heated to a temperature in the range of 60°C to 70°C, thereby artificially accelerating corrosion.

[0110] About one month after the start of the artificially accelerated corrosion, the FOD sensor 14 was fixed by using U-bolts.

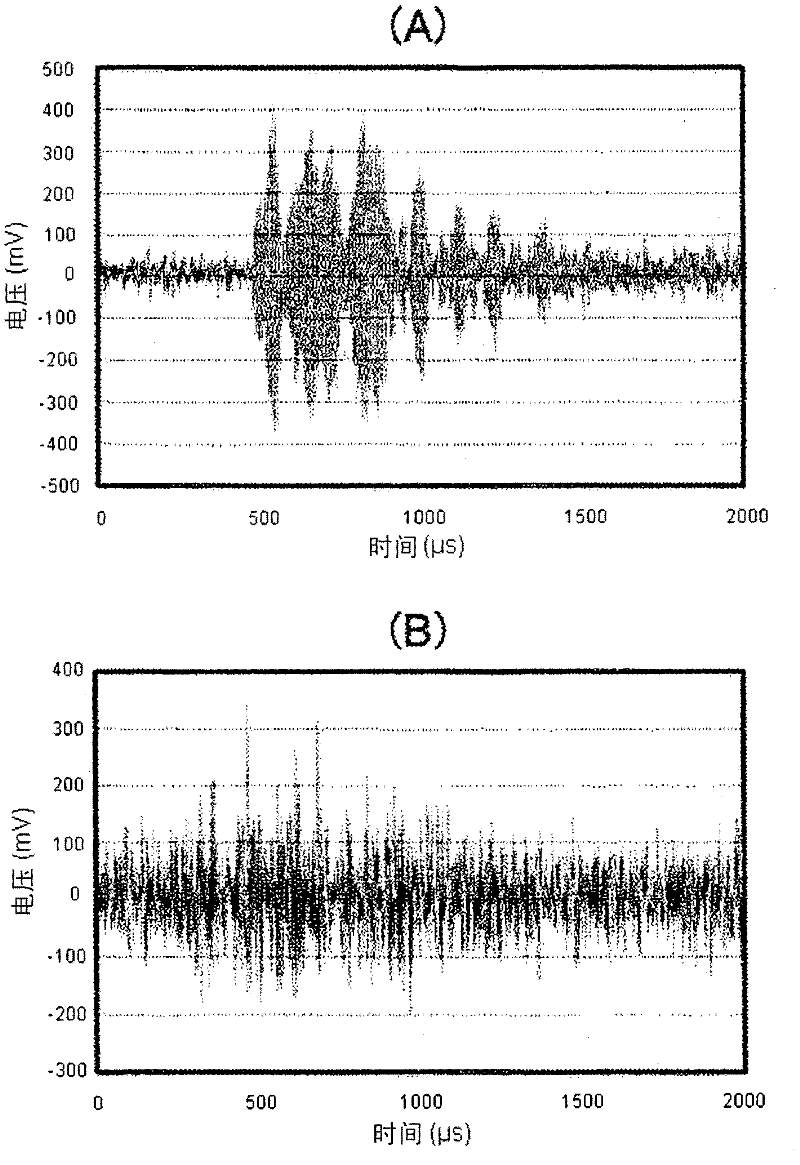

[0111] The silicone oil was heated for 3 hours after starting to determine AE, all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com