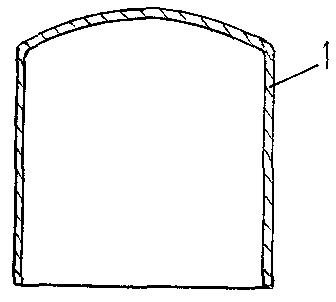

Edible fungus strain preparation method capable of preventing damp cotton plugs in strain bottles or culture bags

A culture bag and cotton plug technology, which is applied in the field of producing edible fungus strains that can prevent the cotton plugs in strain bottles or culture bags from getting wet, can solve the problem of affecting the survival rate and yield of strain production, incomplete moisture-proof effect, and affecting Production efficiency and other issues, to achieve the effect of light processing cost, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

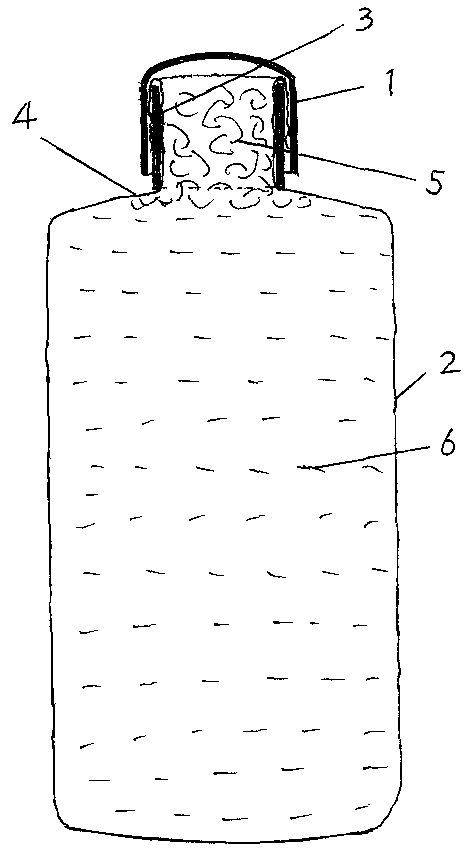

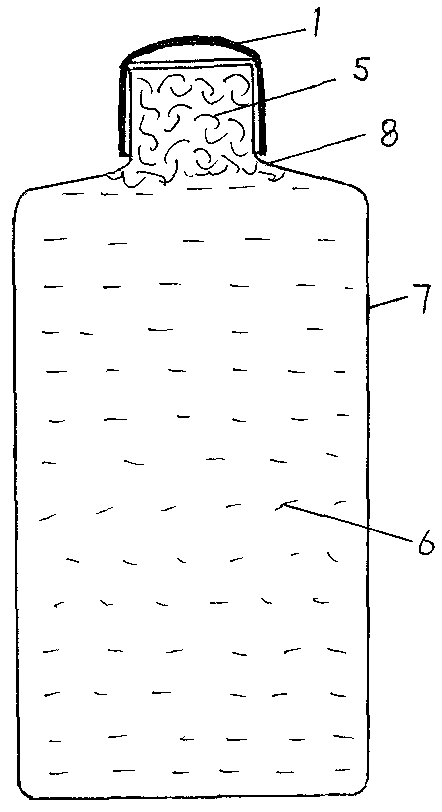

Embodiment Construction

[0014] The following is a specific embodiment utilizing the technical solution of the present invention. This method of the present invention can prevent the edible fungus bacterial classification (referring to the original species or cultivated species) from being wet in the strain bottle or the culture bag, which can be used for To make bacterial strains such as wheat grains (i.e. including making original species such as wheat grains and cultivated species such as wheat grains), the method still includes the following process steps: the one is to produce the mother species (also known as the first-level species), that is, from the fruiting body Purify and rejuvenate to obtain the mother species, the second is to produce (wheat grains, etc.) Utilize original species to produce cultivated species (such as cultivars such as wheat grains, also known as third-level species), as the cultivated species for production (for bacteria that can be directly put into production), it is ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com