Cigarette filter, process for producing the same, and cigarette

一种过滤嘴、香烟的技术,应用在烟油滤芯、烟草、应用等方向,能够解决低过滤嘴硬度、压力降增加、不充分酚除去等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

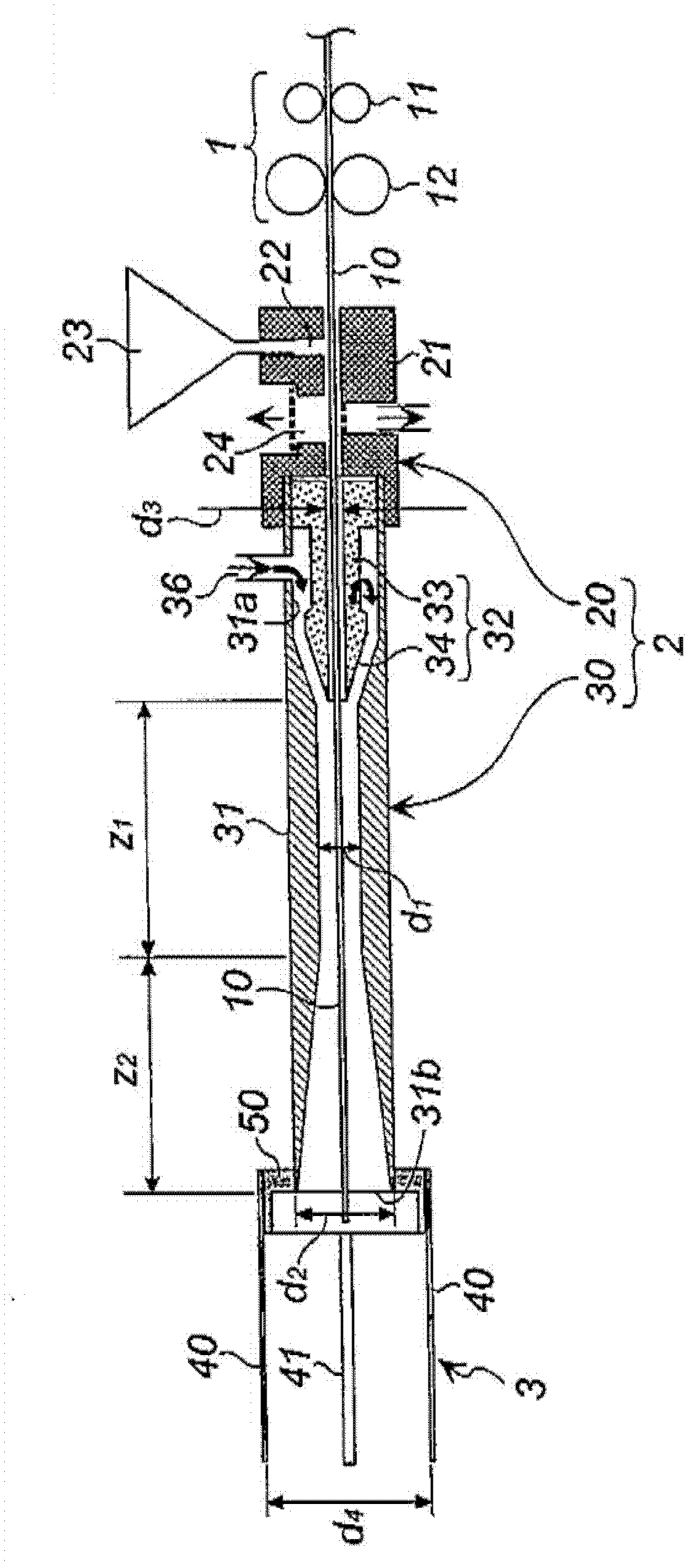

Method used

Image

Examples

Embodiment 1

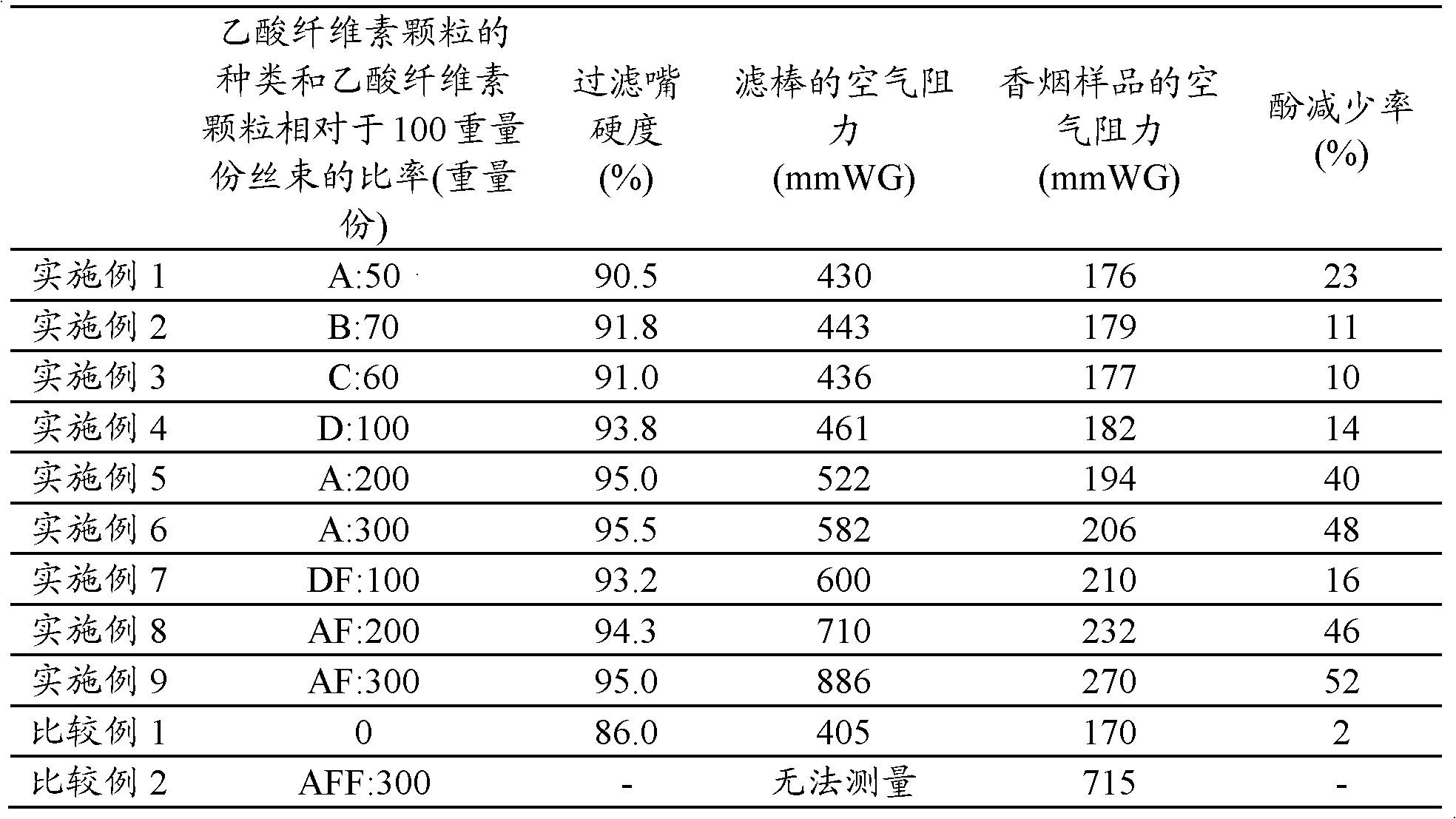

[0090] Cellulose acetate ("L-40", manufactured by Daicel Chemical Industries, Ltd., degree of acetylation: 55.6%) was classified by sieving to obtain cellulose acetate particles A having a particle diameter of "1.0-0.425 mm". The cellulose acetate particles A have a bulk specific gravity of 0.40 and 10.8 m 2 / g of BET specific surface area. Cellulose acetate fiber tow (total Denier: 40,000) was opened to a width of about 20 cm, and triacetin was uniformly sprayed on the opened tow at a ratio of 6 parts by weight to 100 parts by weight of tow triacetin, and then a charcoal adding machine was used to relatively The cellulose acetate particles A were uniformly sprayed at a ratio of 50 parts by weight to 100 parts by weight of the silk fiber particles A. The resulting tow was wrapped with wet paper, and then cut with a cutter to obtain a filter rod having a length of 100 mm. The resulting filter rod was further cut to a length of 20 mm to obtain a filter tip sample. The filter...

Embodiment 2

[0092] Cellulose acetate ("LT-55", manufactured by Daicel Chemical Industries, Ltd., degree of acetylation: 60.8%) was classified by sieving to obtain cellulose acetate particles B having a particle diameter of "1.0 to 0.425 mm". The cellulose acetate particles B have a bulk specific gravity of 0.53 and 3.1 m 2 / g of BET specific surface area. A filter sample was manufactured in the same manner as in Example 1, except that cellulose acetate particles B were used instead of cellulose acetate particles A at a ratio of 70 parts by weight relative to 100 parts by weight of tow particles B. The filter sample has a 1.4m 2 / g of BET specific surface area.

Embodiment 3

[0094] Cellulose acetate ("LM-80", manufactured by Daicel Chemical Industries, Ltd., degree of acetylation: 52.0%) was classified by sieving to obtain cellulose acetate particles C having a particle diameter of "1.0 to 0.425 mm". The cellulose acetate particles C have a bulk specific gravity of 0.29 and 2.5 m 2 / g of BET specific surface area. A filter sample was manufactured in the same manner as in Example 1, except that cellulose acetate particles C were used instead of cellulose acetate particles A at a ratio of 60 parts by weight relative to 100 parts by weight of tow particles C. The filter sample has a 0.9m 2 / g of BET specific surface area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com