Novel solid-liquid separation leaching device

A technology of suction filtration device and vacuum device, which is applied in the direction of separation method, filtration separation, filtration circuit, etc., which can solve the problems of hindering the passage of filter holes, reducing the filtration speed, difficult filtration, etc., so as to reduce the loss of solid matter and avoid leakage of filtration , The effect of saving time in the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In a conventional manner, in a container with a volume of 3 L, lanthanum chloride and sodium bicarbonate were reacted to form a precipitate of lanthanum carbonate.

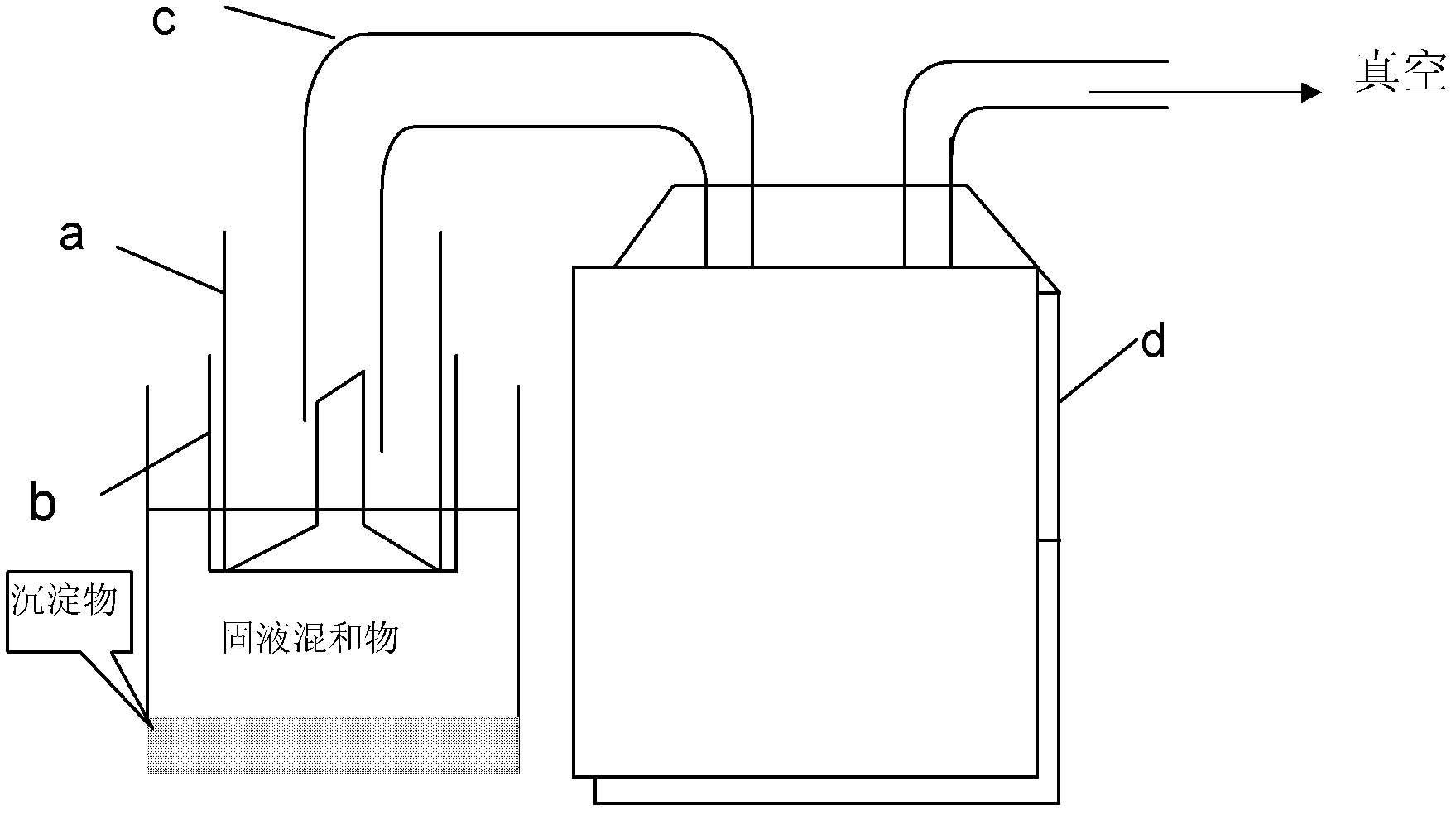

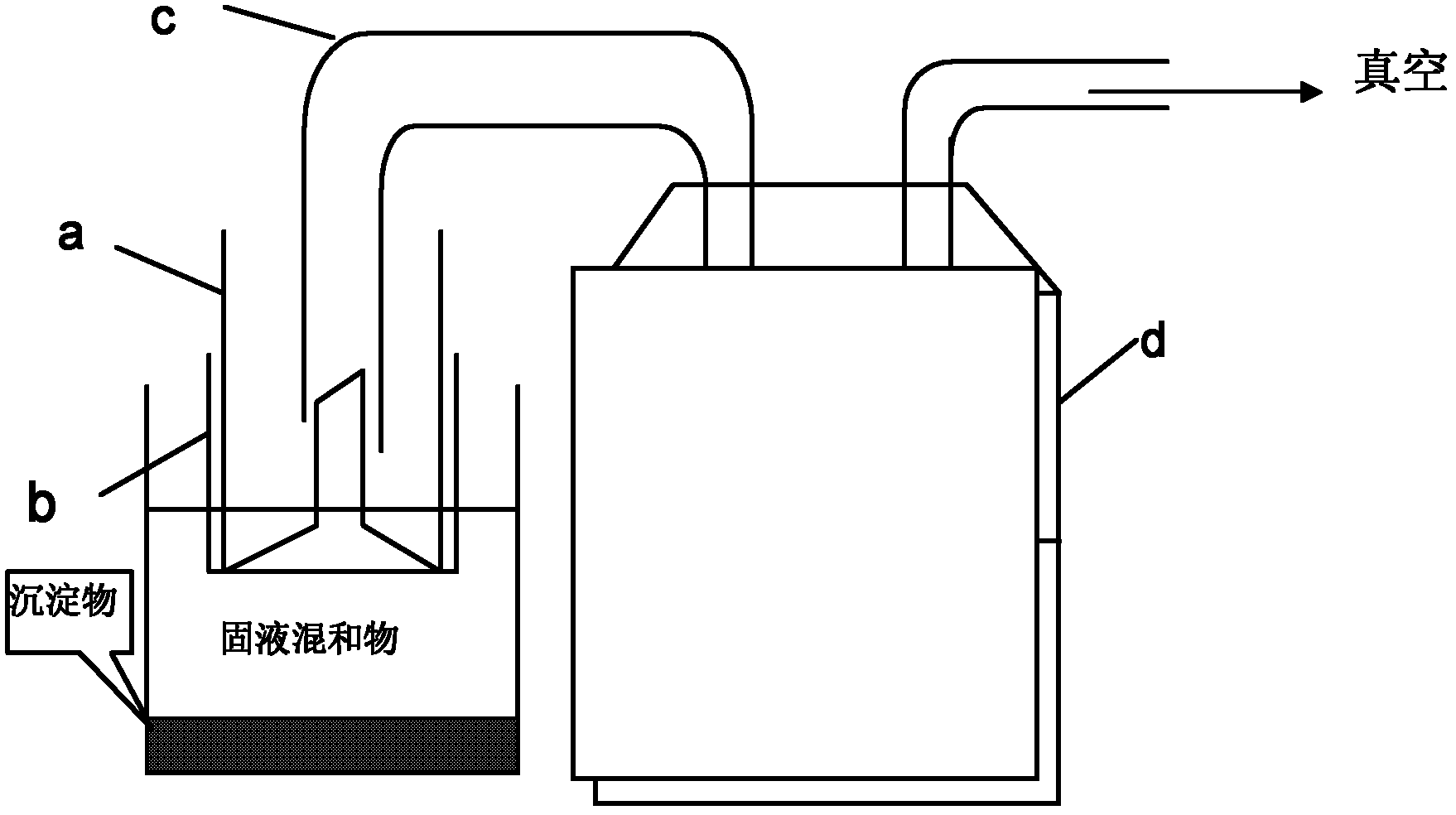

[0058] Install the suction filter device so that the suction filter device includes a suction filter with an upward outlet and a vacuum device. The suction filter includes a cup-shaped funnel a with an upward outlet and a filter cloth b. The filter cloth b is fixed on the funnel a by binding, and the vacuum device It mainly includes rubber conduit c, liquid storage tank d and vacuum system.

[0059] The suction filter is placed in the solid-liquid mixed solution where the lanthanum carbonate precipitates, and in order to make the suction filter float on the liquid surface, a float is set for the suction filter. Turn on the air pump switch, run the vacuum system, adjust the vacuum degree to 0.09-0.1MPa, and perform suction filtration until solid-liquid separation is achieved.

Embodiment 2

[0061] In a container with a volume of 2L, silver nitrate reacts with potassium iodide to form a silver iodide precipitate.

[0062] The suction filtration device is installed as in Example 1, the difference is that the filter element made of sintered glass is fixed on the bottom of the cup-shaped funnel with the outlet upward by bonding.

[0063] Place the suction filter in the solid-liquid mixed solution where the silver iodide precipitates, and set the float for the suction filter to float on the liquid surface. In order to make the solid-liquid separation more effective, before running the vacuum system for separation, let the solid-liquid mixture stand still enough to allow the solid matter to settle at the bottom. Then turn on the pump switch, run the vacuum system, adjust the vacuum degree to about 0.1MPa, and perform suction filtration until solid-liquid separation is achieved.

Embodiment 3

[0065] In a container with a capacity of 3L, lanthanum chloride and sodium fluoride react to form a lanthanum fluoride precipitate.

[0066] Install the suction filtration device as in Example 1, the difference is that after running for a period of time, the funnel is taken out, and the sediment on the surface of the filter medium is cleaned; After fully standing, continue suction filtration until solid-liquid separation is achieved.

[0067] After suction filtration, sprinkle a small amount of water on the solid, let it stand for a while, then drain it, and then further dry it or use a desiccant to absorb moisture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com