Slag removal and oil separation tank

A technology of grease traps and partitions, which is applied in the direction of grease/oily substance/floating matter removal devices, filtration separation, separation methods, etc., which can solve the problems of inability to discharge, oil discharge pipelines that cannot achieve a good oil discharge effect, and environmental pollution and other problems to achieve the effect of convenient elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

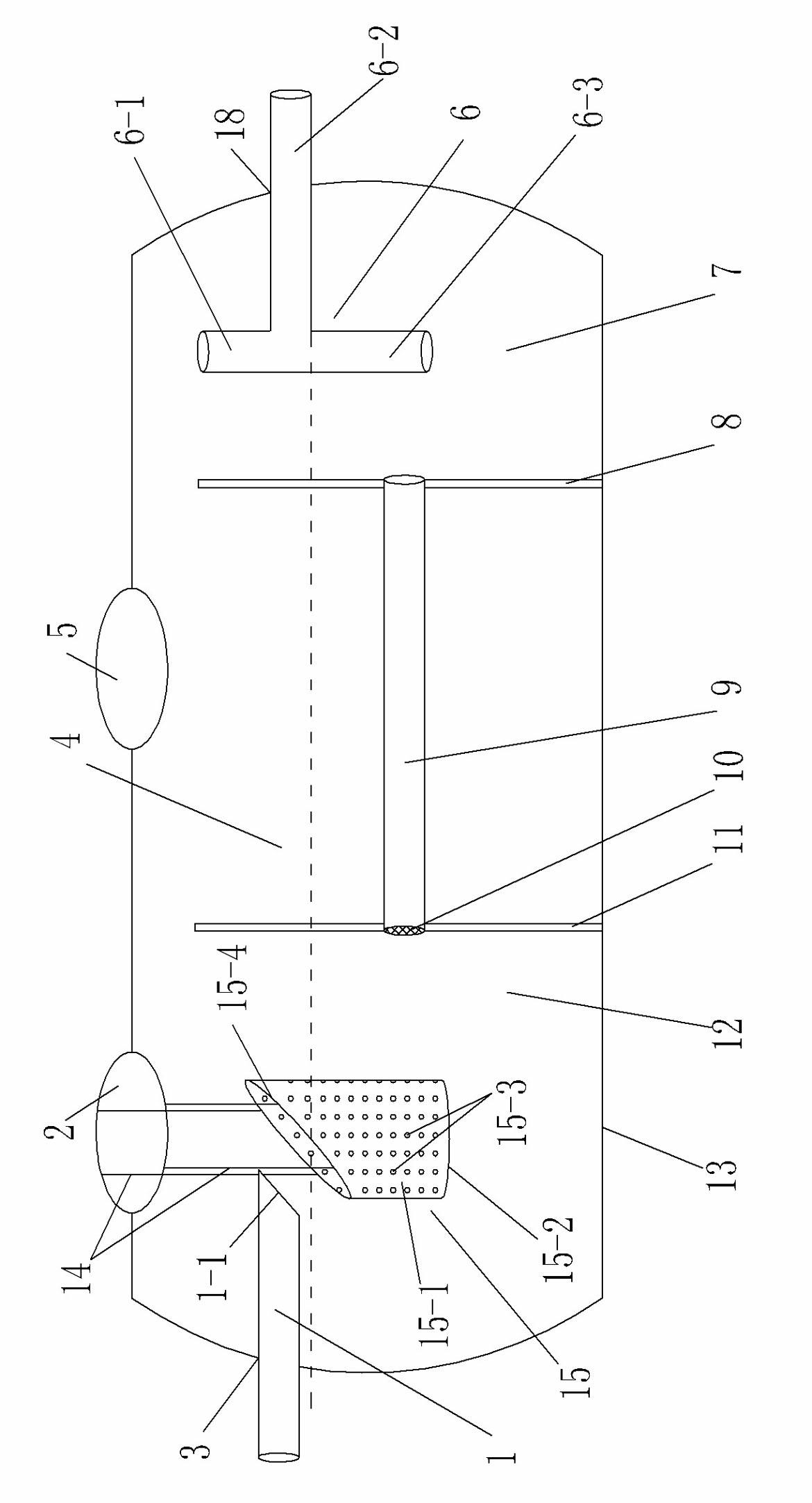

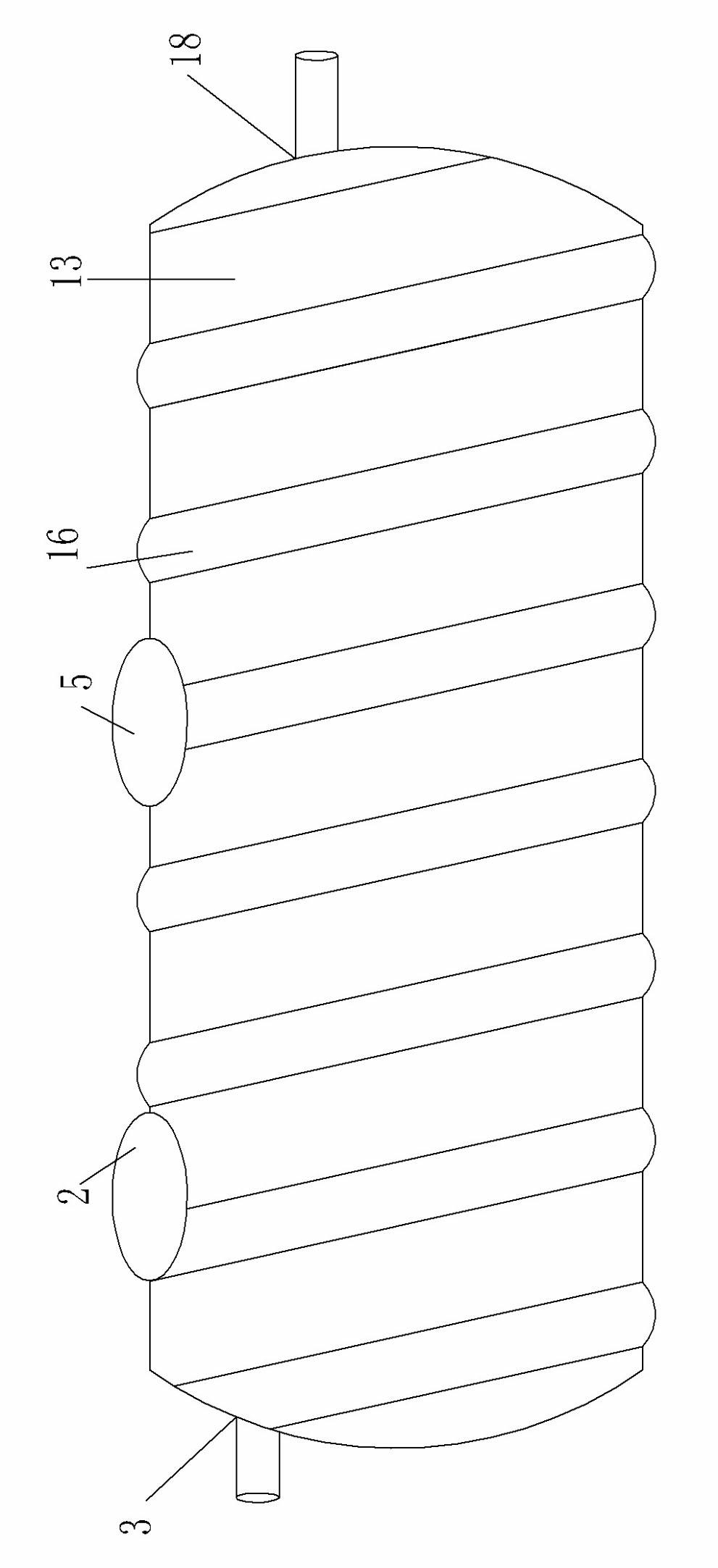

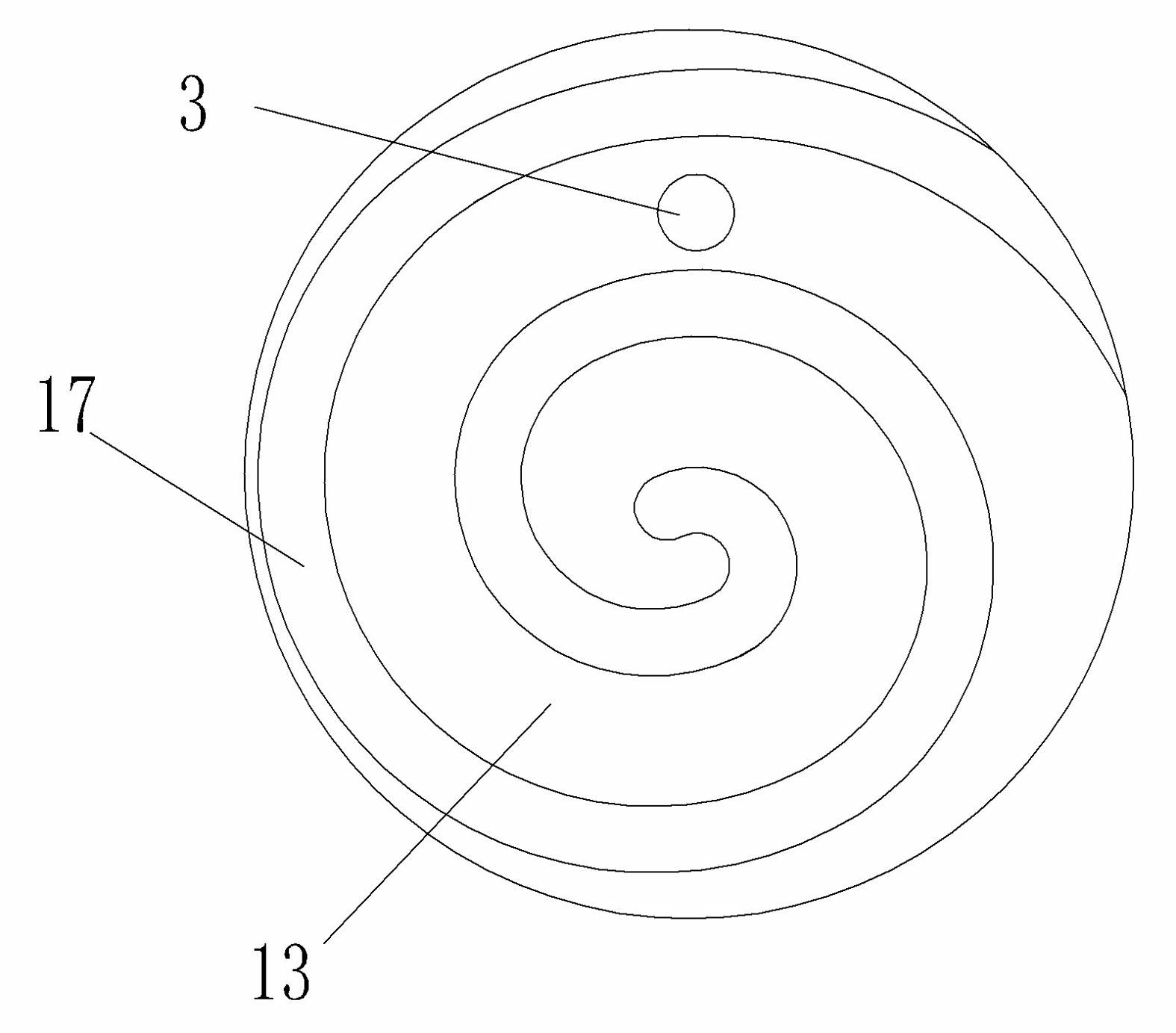

[0022] An embodiment of a slag removal grease trap is for example Figure 1~3 Shown: includes a sealed tank body 13, the tank body 13 is made of integral glass fiber reinforced plastic material, the two ends of the tank body 13 are provided with a vortex-shaped reinforcement structure 17, and the outer periphery of the tank body 13 is provided with a threaded reinforcement structure 16, and the vortex-type reinforcement structure 16 is provided. The tail end of the reinforcing structure 17 is connected with the head end of the threaded reinforcing structure 16 . Inside the tank body 13, a first partition 11 and a second partition 8 are arranged side by side along the corresponding sewage flow direction, and the first partition board 11 and the second partition 8 divide the tank body 13 into a first-stage oil-water separation chamber connected to the upper part. 12. The oil storage bin 4 and the secondary oil-water separation bin 7. The tank body 13 is provided with a slag outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com