Processing technology for plate hub of driven plate assembly and mould component adopted in the processing technology

A processing technology and disk hub technology, which is applied in the field of processing technology of automobile clutch driven disc assembly, can solve the problems of high mold manufacturing and management costs, difficult control of verticality requirements, and affecting vehicle shaking, etc., to reduce manufacturing costs. and management costs, cost minimization, and the effect of improving mold change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

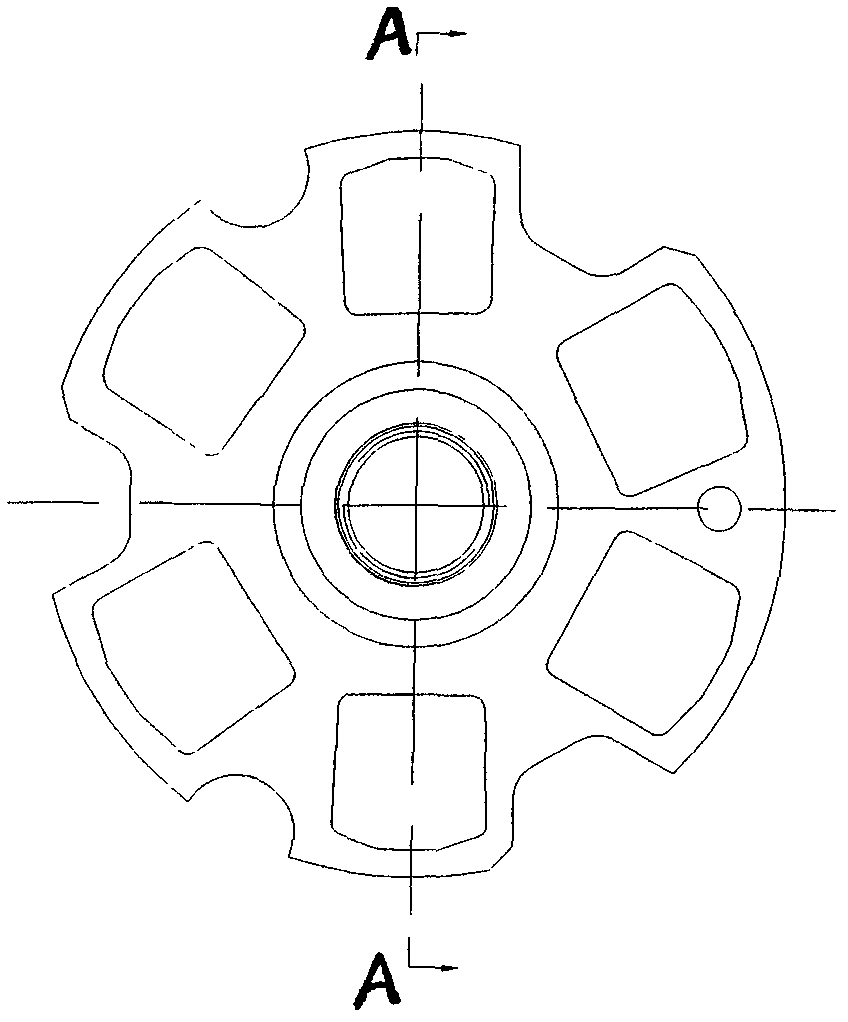

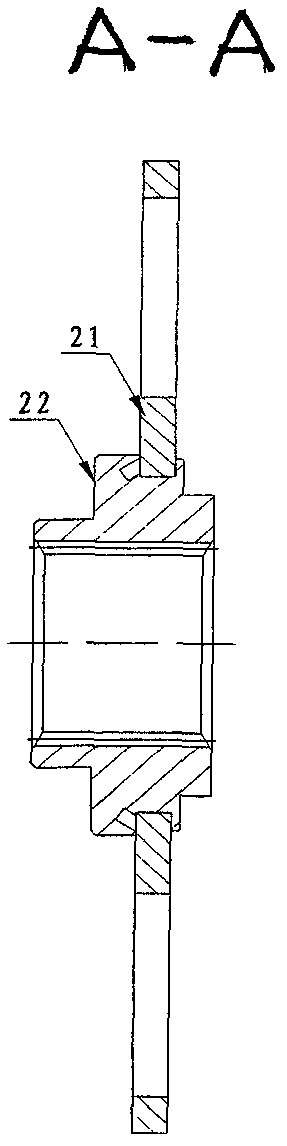

[0022] refer to Figure 1 to Figure 4 As shown, the disk hub processing technology of the driven disk assembly of the present invention is: the disk hub is divided into two parts: a disk hub sheet 21 and a disk hub core 22, and the disk hub sheet 21 is made of a steel plate through shearing, stamping, leveling, Processed by heat treatment, the disc hub core 22 is processed from its blank through lathe processing surface, groove, tooth punching, quenching and tempering treatment; then the disc hub core and sheet are assembled and riveted into one by (hydraulic pressure) , and then finish the inner hole of the car, shot blasting, spline broaching, and anti-rust treatment, so as to complete the entire processing process of the hub and produce the finished hub.

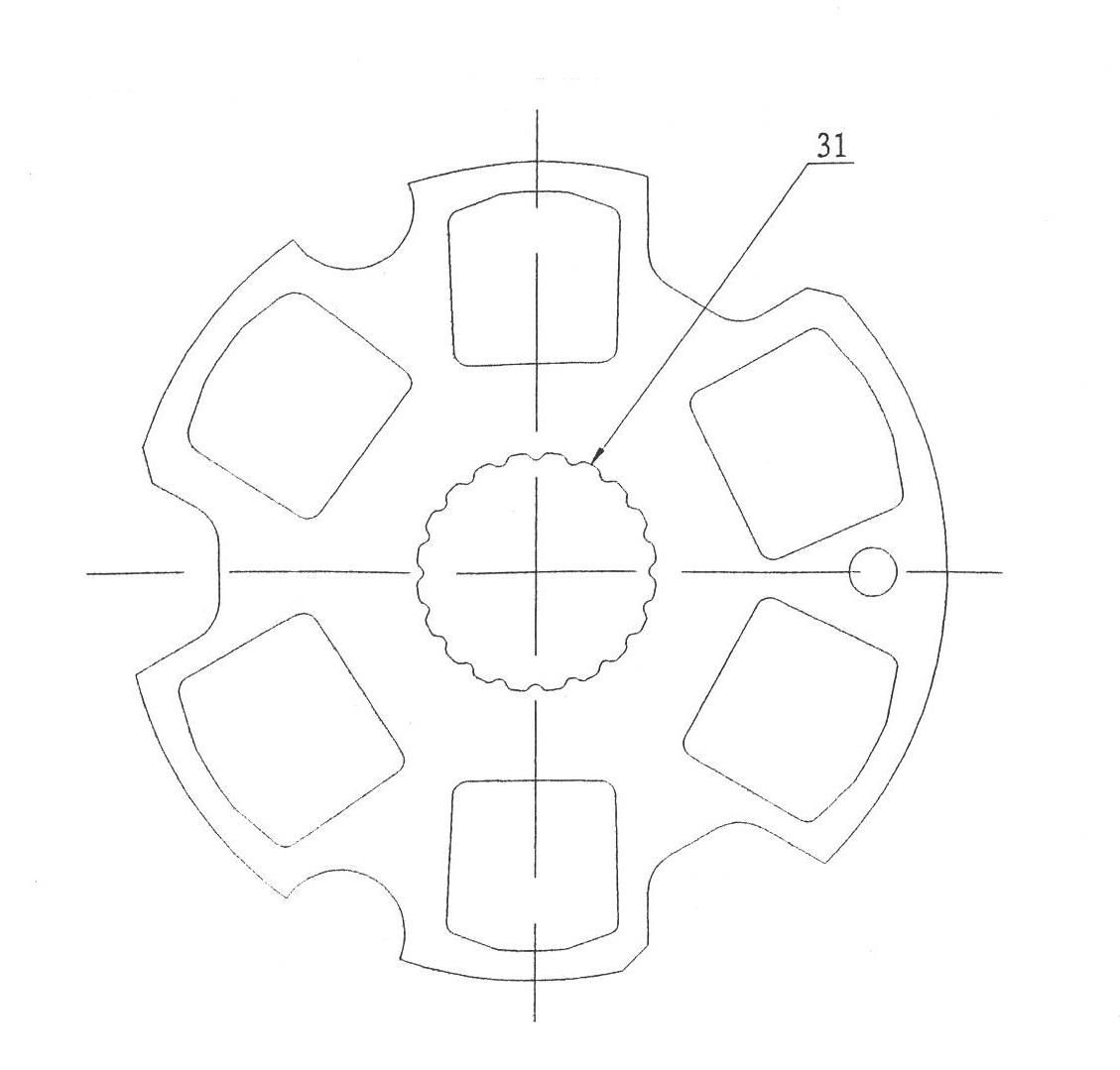

[0023] Such as Figure 5 , Image 6 As shown, the described disc hub core groove processing refers to that after the disc hub core passes through the surface of the finish car, it is placed on the disc hub core and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com