Automatic scar removing machine for timbers

A wood and automatic technology, applied in fixed drilling machines and other directions, can solve the problems of low processing efficiency, high labor intensity, different shrinkage and expansion, etc., and achieve the effect of improving work efficiency, simplifying processing technology, and being convenient to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

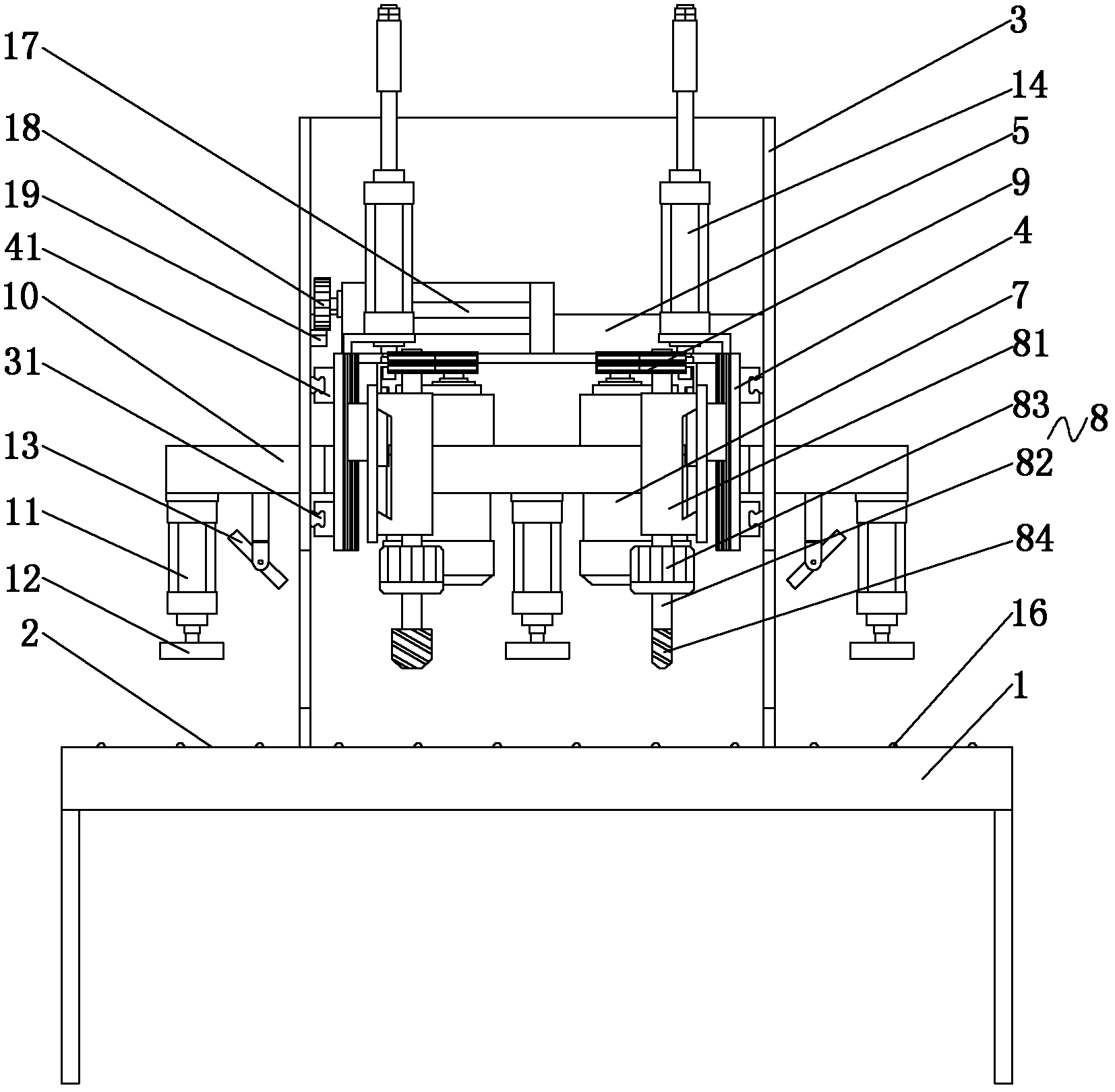

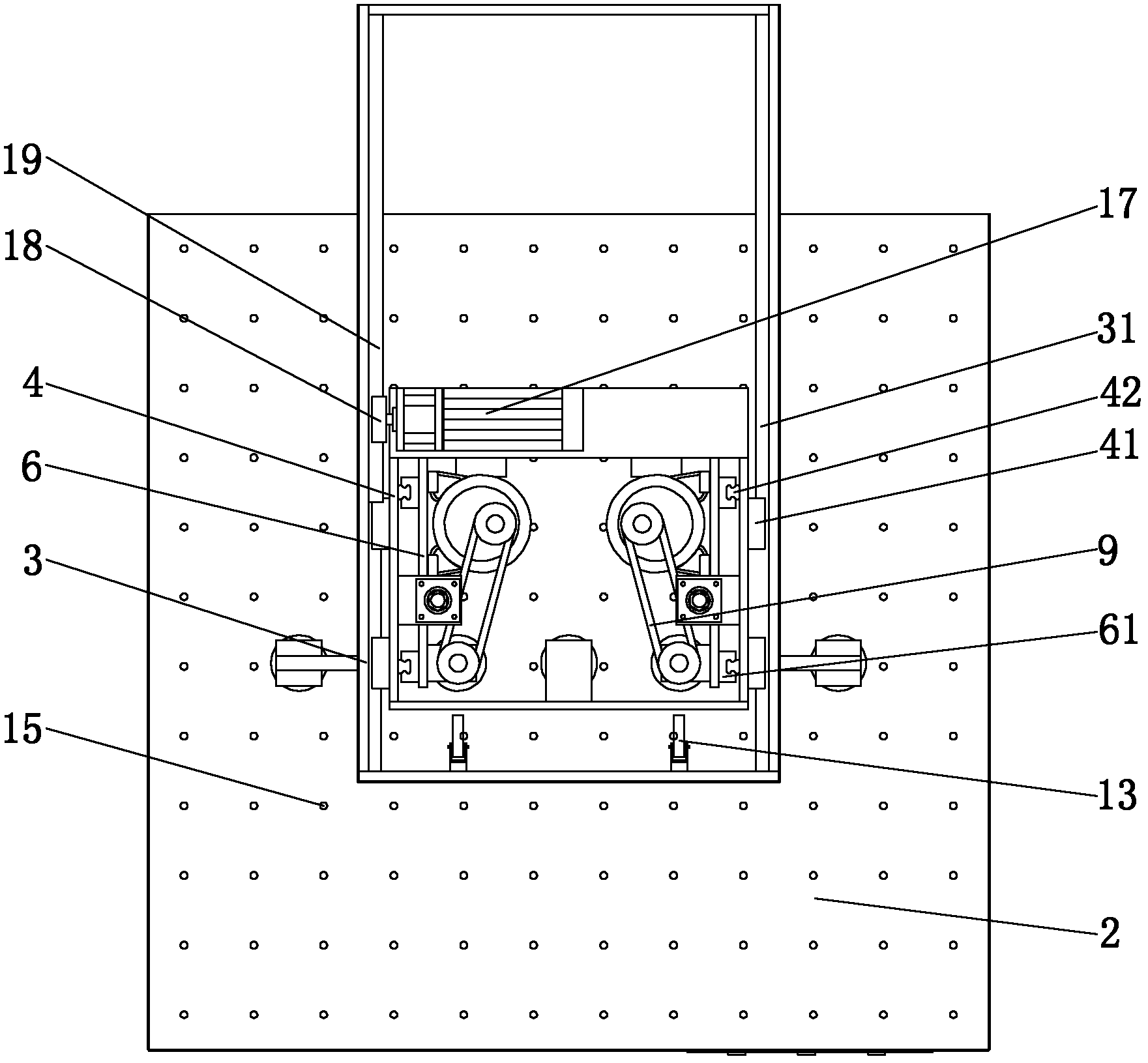

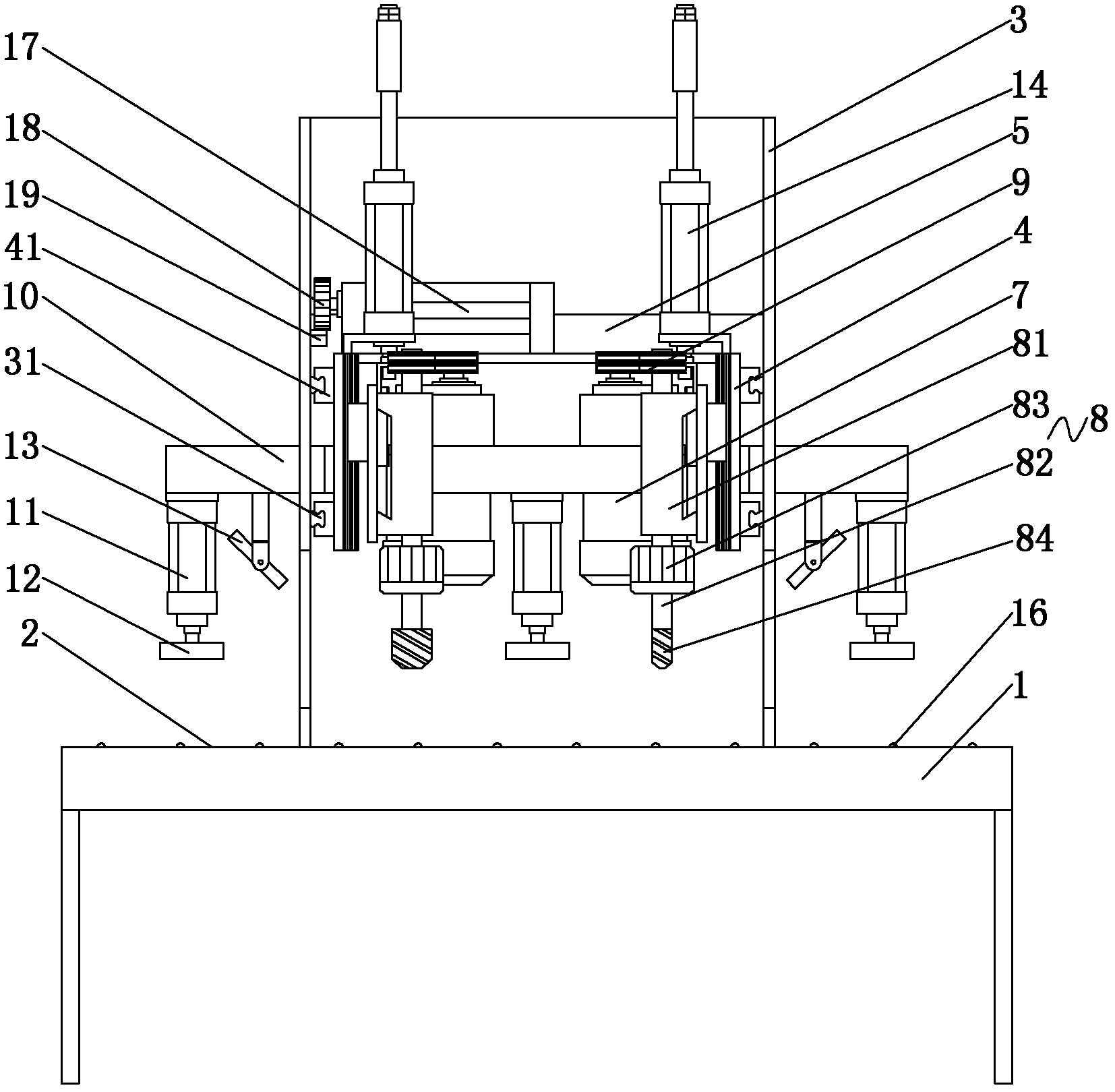

[0015] Such as figure 1 or figure 2 As shown, the wood automatic scar removal machine of the present invention comprises a frame 1, an air flotation workbench 2 is arranged on the frame 1, and two support plates 3 are arranged on the air flotation workbench 2 upper sides of the frame 1, and the two support plates The front and rear moving plates 4 that move forward and backward along the support plate 3 are respectively arranged on the plate 3, and cross beams 5 are arranged between the front and rear moving plates 4 on both sides, and the up and down moving plates that move up and down along the front and rear moving plates 4 are respectively provided on the two front and rear moving plates 4 6. Turning milling motor 7 and drill bit device 8 are fixed on each side up and down moving plate 6. Turning milling motor 7 drives the drill bit 84 in the drill bit device 8 to rotate through the transmission belt 9. The drill bit 84 is located above the air flotation workbench 2. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com