Method for printing cigarette packet snowflake patterns by using improved intaglio printing press

A gravure printing machine, an improved technology, applied in the direction of printing, printing, and printing process for producing special varieties of printed matter, which can solve problems such as overprinting instability, the speed difference is far, and the quality of the finished product is affected, and the height difference between the front and rear is reduced. , the effect is consistent, to ensure the effect of receiving light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

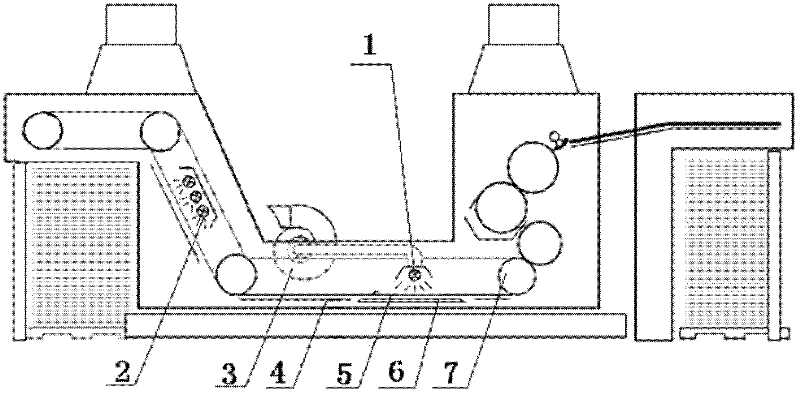

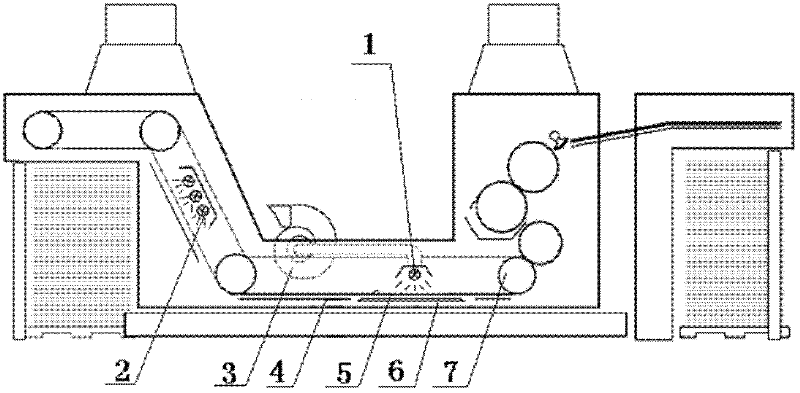

[0034] Embodiment 1: A kind of " red golden dragon " product that adopts a kind of improved gravure printing machine of the present invention to be used for printing the method for printing cigarette package snowflake picture, prints according to the following steps:

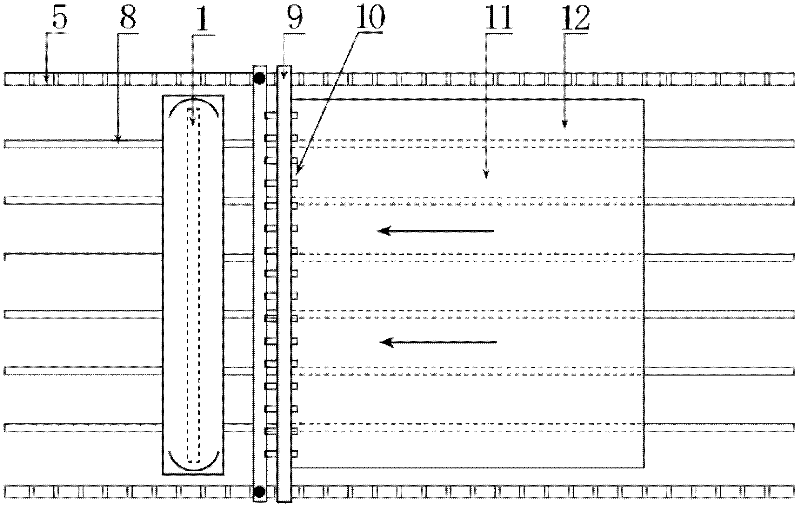

[0035] (1) "60 line 55u" laser engraving is used to make gravure; when engraving, if there is a net pattern on the paper, the angle of the concave hole should be consistent with the net pattern on the paper, so as to avoid faint moiré patterns and affect the snowflake effect;

[0036] (2) UV ink is used for printing; coarse snowflake (Shensaier SRA-2000HH7) and fine snowflake (Shensaier SRA-2000YZ3) inks are used, and the ratio is 3:2. Xaar ABR-020C), the ratio of ink to thinner is 15:1, too much thinner will affect the snowflake effect.

[0037] (3), UV patterning lamp 1 chooses metal halide UV lamp, power 4500W; make UV ink detonate ink under the irradiation of UV patterning lamp after printing, can form delic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com