Water-drop type carbon fiber tyre bead core used for tyre and forming method thereof

A bead core and water drop type technology, which is applied to tire parts, tires, tire edges, etc., can solve the problems of relative sliding of the bead core and apex rubber core, the difficulty of manufacturing and processing, and the inability to guarantee good results. Achieve the effect of easy operation, strong tensile resistance, and avoid tire rim accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

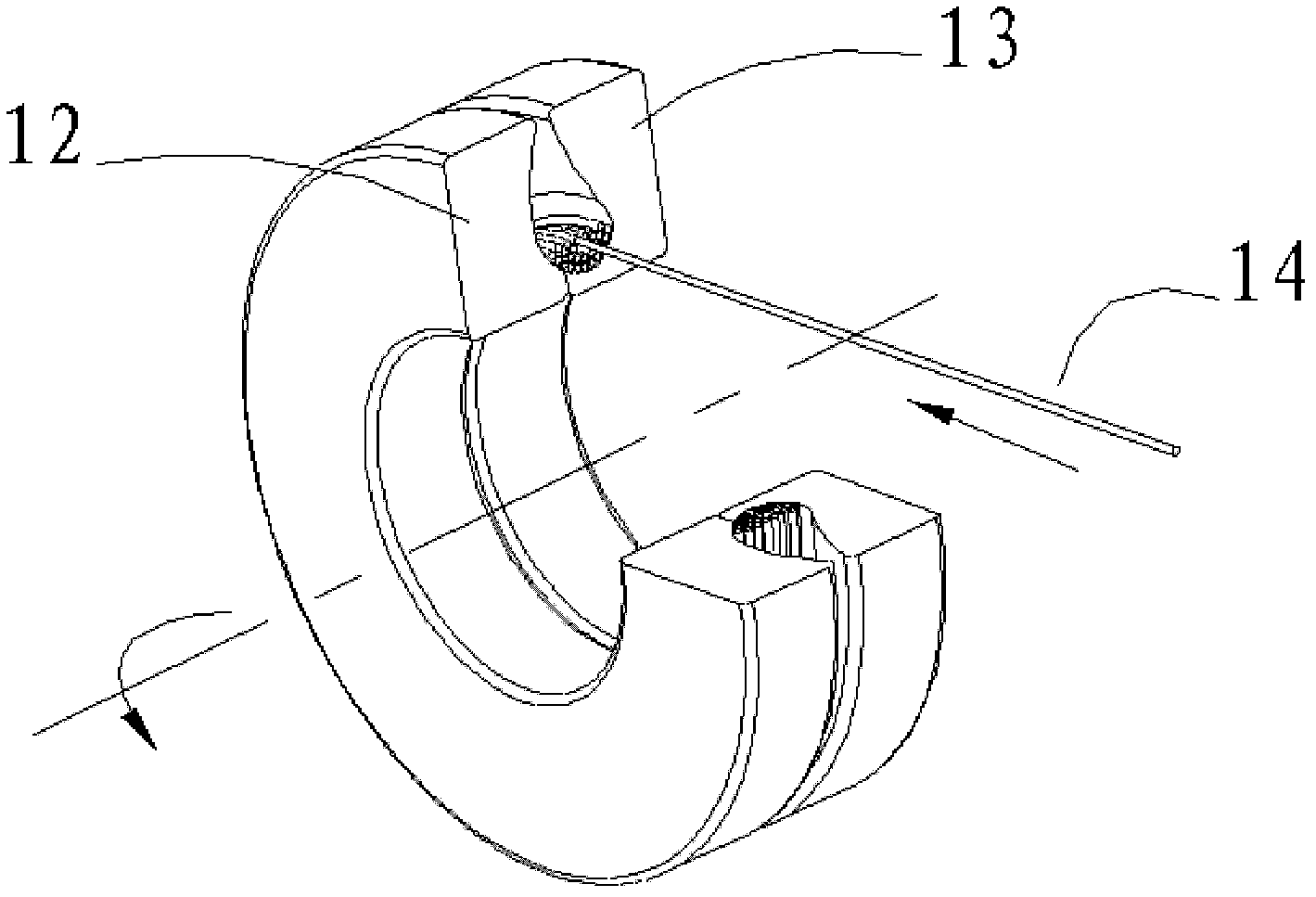

[0027] An embodiment of a water-drop carbon fiber bead core for a tire according to the present invention will be described below with reference to exemplary embodiments.

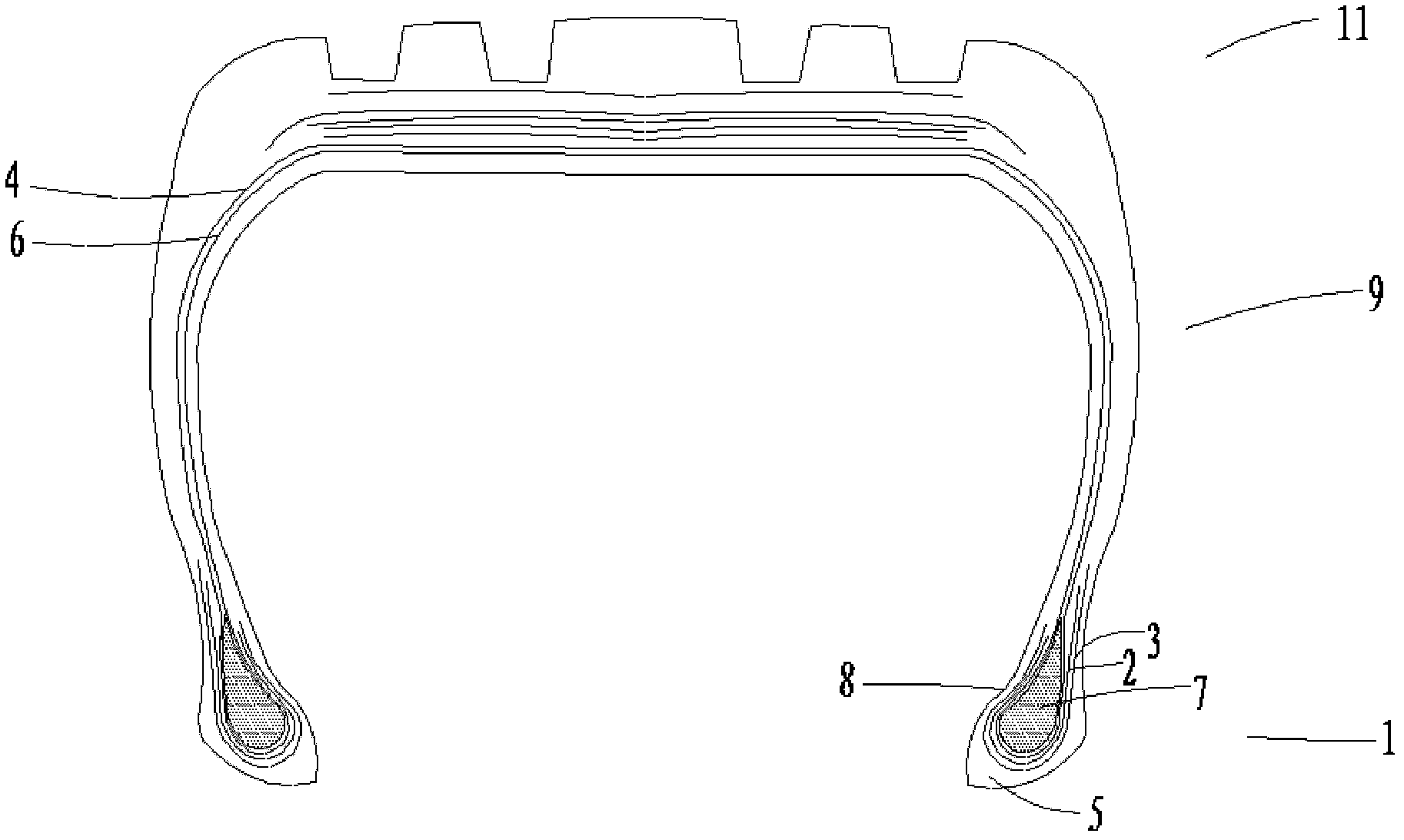

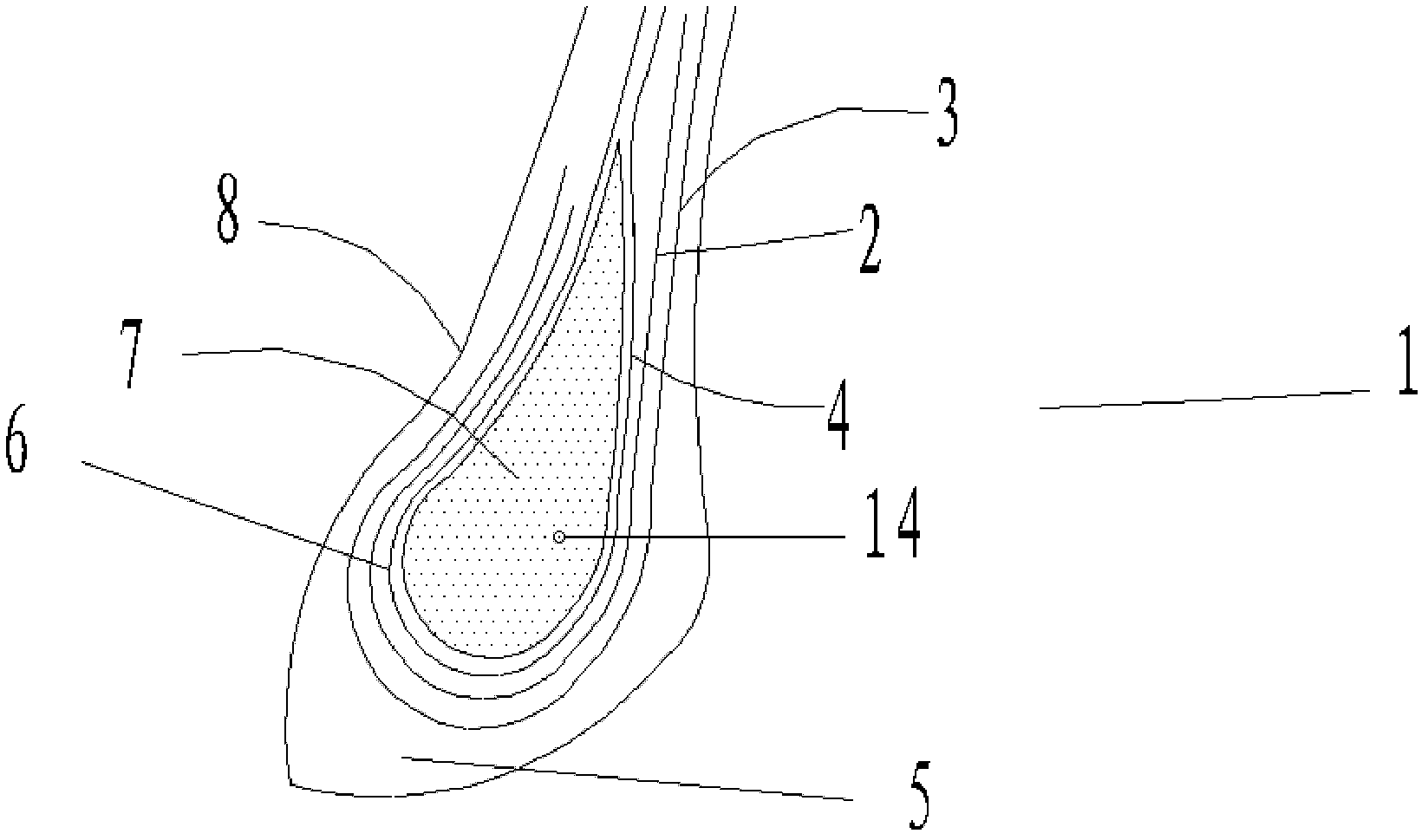

[0028] Such as figure 1 and figure 2 As shown, according to the aviation tire 11 of the present invention, its bead 1 is mainly composed of a water drop-shaped carbon fiber bead core 7, a first bead reinforcing layer 2, a second bead reinforcing layer 3, bead wear-resistant rubber 5, The carcass cord layer 6, the inner liner layer 8 and the turn-up carcass cord layer 4 are composed of the carcass cord layer 4, which are connected with the sidewall 9 from the position of the section.

[0029] The water drop-shaped carbon fiber bead core 7 is tightly wound by the carcass cord layer 6 and the turned-up carcass cord layer 4, forming a seamless connection with each other. The radial inner side of layer 4 is tightly wound by the first bead reinforcing layer 2 and the second bead reinforcing layer 3 in sequence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com