Insulated roller profile guide rail assembly

A technology of rollers and guide rails, applied in the direction of rails, rail contact components, railway car body parts, etc., can solve the problems of excessive partial discharge, easy failure of ceramic universal balls, unreliable connection of small metal balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

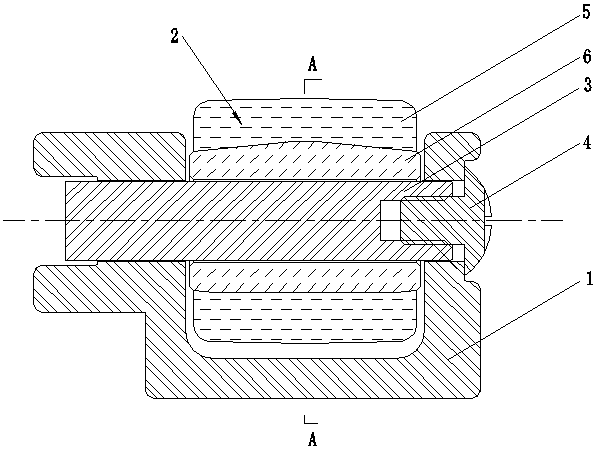

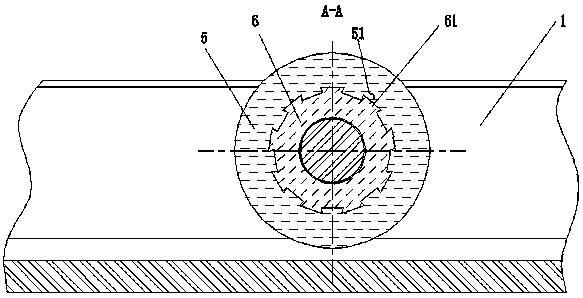

[0028] The present invention is further described below with reference to the accompanying drawings and the given embodiments, but is not limited thereto.

[0029] like figure 1 , 2 , 3, 4, and 5, an insulating roller profile guide rail assembly includes a guide rail profile 1 and a composite material roller 2, the composite material roller 1 includes a fixed shaft 3, and the composite material roller 2 The fixed shaft 3 and the guide rail The profile 1 is fixedly connected; the composite material roller 2 also includes an inner roller 6 and an outer roller 5, the fixed shaft 3 is arranged in the shaft hole of the inner roller 6, and the fixed shaft 3 and the inner roller 6 are gap-fitted, so The inner roller 6 is arranged in the inner hole of the outer roller 5, and the inner roller 6 is tightly fitted with the outer roller 5;

[0030] The inner roller 6 is formed by injection molding of a mixture of glass fiber reinforced nylon and a solid lubricating material, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com