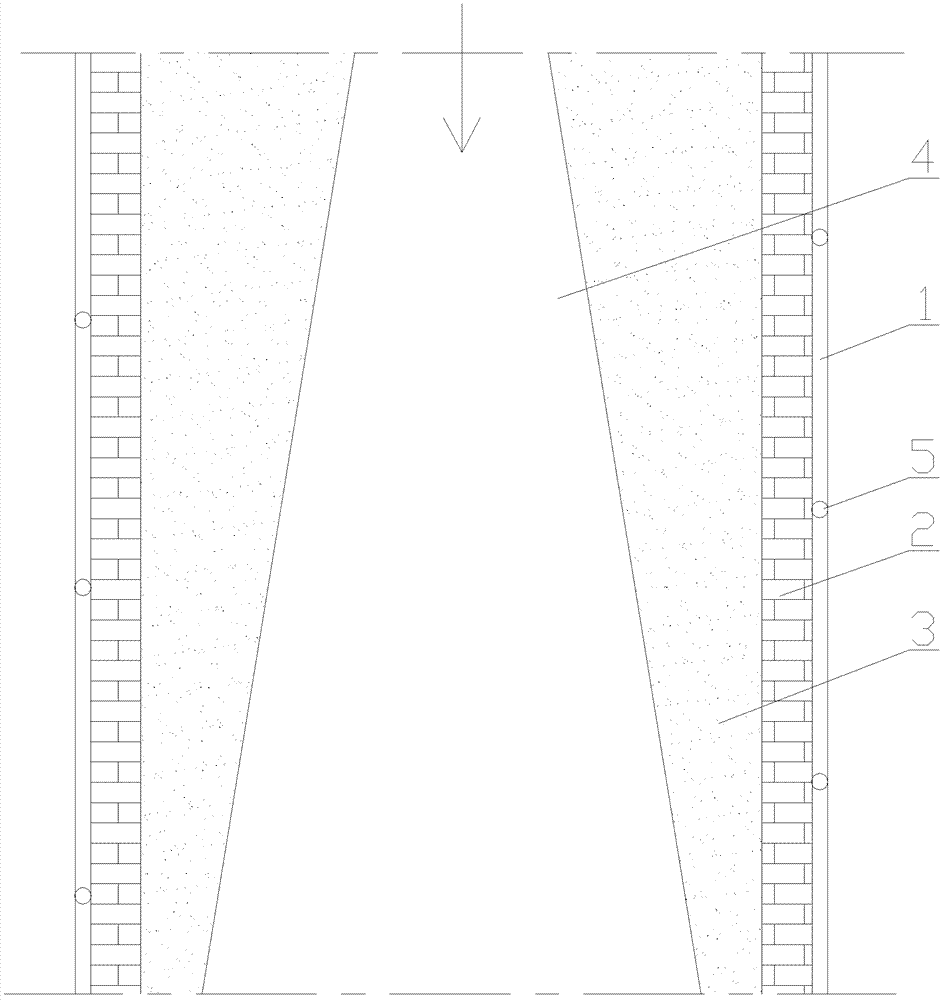

Single-iron notch blast furnace iron storage type tapping main channel

A blast furnace and iron storage technology, which is applied in the field of improvement of castable structure and formula of single-taphole blast furnace iron storage type tapping main ditch, can solve problems such as hidden dangers, increased consumption of refractory materials, late tapping of blast furnace, etc., and achieves extension The effect of service life, material cost saving and economic benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The formula of single-taphole blast furnace iron storage type tapping main ditch castable includes the first half (ie: the first half of the iron drop point) and the second half (ie: the second half of the main ditch), the first half and the second half are made of Different formulas, the mass ratio of each component in the first half is: brown corundum or dense corundum: 42 parts, silicon carbide: 28 parts, white corundum: 16 parts, α-Al 2 o 3 : 5 parts, silica powder: 2 parts, spherical pitch: 5 parts, metal silicon powder: 3 parts, chromium oxide: 0.2 parts, boron nitride: 0.6 parts, nano-silicon aluminum gel powder: 1.2 parts, pure calcium aluminate Cement: 2 parts, organic fiber: 0.1 part, metal aluminum powder: 0.1 part, rubidium hydroxide: 0.1 part, first composite additive: 2 parts; the mass ratio of each component in the second half is: brown corundum or dense corundum: 42 parts, silicon carbide: 28 parts, white corundum: 16 parts, α-Al 2 o 3 : 5 parts, sili...

Embodiment 2

[0019] The formula of single-taphole blast furnace iron storage type tapping main ditch castable includes the first half (ie: the first half of the iron drop point) and the second half (ie: the second half of the main ditch), and the first half and the second half use different The formula, the mass ratio of each component in the first half is: brown corundum or dense corundum: 45 parts, silicon carbide: 25 parts, white corundum: 17 parts, α-Al 2 o 3 : 4 parts, silica powder: 3 parts, spherical pitch: 4.8 parts, metal silicon powder: 3.3 parts, chromium oxide: 0.3 parts, boron nitride: 0.8 parts, nano-silicon aluminum gel powder: 1.4 parts, pure calcium aluminate Cement: 1.8 parts, organic fiber: 0.2 parts, metal aluminum powder: 0.1 parts, rubidium hydroxide: 0.08 parts, first composite additive: 2.2 parts; the mass ratio of each component in the second half is: brown corundum or dense corundum: 45 parts, silicon carbide: 25 parts, white corundum: 18 parts, α-Al 2 o 3 : 4 ...

Embodiment 3

[0021] The formula of single-taphole blast furnace iron storage type tapping main ditch castable includes the first half (ie: the first half of the iron drop point) and the second half (ie: the second half of the main ditch), and the first half and the second half use different The formula, the mass ratio of each component in the first half is: brown corundum or dense corundum: 40 parts, silicon carbide: 30 parts, white corundum: 15 parts, α-Al 2 o 3 : 6 parts, silica powder: 1 part, spherical pitch: 5 parts, metal silicon powder: 4 parts, chromium oxide: 0.2 parts, boron nitride: 0.7 parts, nano-silicon aluminum gel powder: 1.3 parts, pure calcium aluminate Cement: 2.4 parts, organic fiber: 0.2 parts, metal aluminum powder: 0.1 parts, rubidium hydroxide: 0.09 parts, first composite additive: 2.3 parts; the mass ratio of each component in the second half is: brown corundum or dense corundum: 40 parts, silicon carbide: 30 parts, white corundum: 15.3 parts, α-Al 2 o 3 : 4.7 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com