Enzyme-containing fabric detergent with synergistic anticorrosion effect

A technology for anti-corrosion and detergent, applied in detergent compositions, detergent compounding agents, soap detergent compositions, etc., can solve problems such as liquid detergents that have not yet appeared, reduce quality risks, enhance performance, and improve products. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of each embodiment is the same as the conventional fabric detergent preparation method, and the main steps are as follows:

[0039] 1. Quantitatively weigh each component, add surfactant and other additives in sequence, and stir evenly;

[0040] 2. Finally, adjust the pH value to be less than 9, and add preservatives.

[0041] The anticorrosion performance test method of each embodiment is as follows:

[0042] 1. Linear regression test experiment

[0043] Add different preservatives and their proportions to the detergent, and screen out the preservative compound system with synergistic effect by linear regression method. Linear regression test The time required for the experimental microbial flora to decrease by one decimal (expressed in D value), that is, the time required for 90% inactivation of the microbial flora contacted with the preservative.

[0044] 1. Stimulate the experimental microorganisms

[0045] The microorganisms used in the c...

Embodiment 1~7

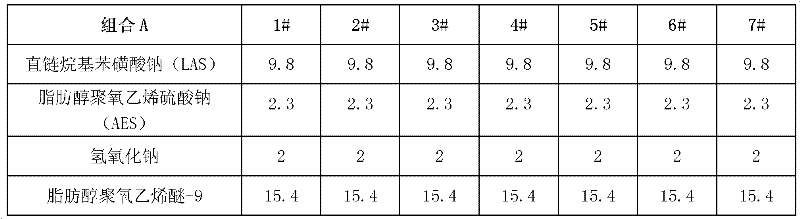

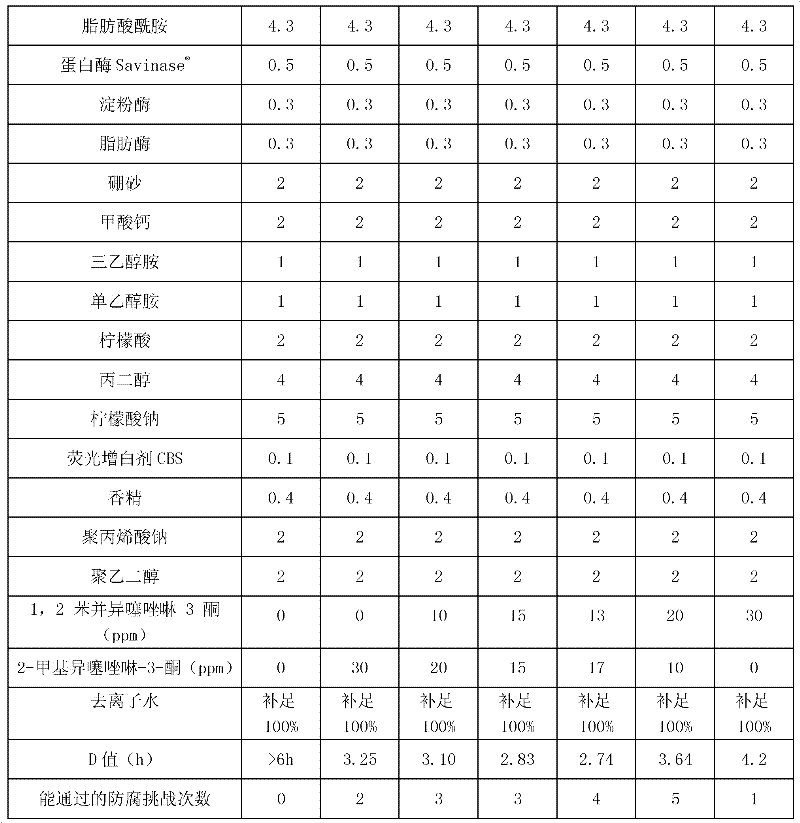

[0058]

[0059]

[0060] In embodiment 1-7, add two kinds of preservatives of different concentration ratio, add 10 6 coli, test the colony concentration at intervals of 1h, 2h, 3h, and 4h. The negative logarithm of the colony concentration was plotted against the time to calculate the D value.

[0061] It can be seen from the calculated D value that when adding the preservative with a total concentration of 30ppm in the above examples, the weight of 1,2-benzisothiazolin-3-ketone and 2-methylisothiazolin-3-ketone When the ratio is 1:2, 1:1, 1:1.3, 2:1, it has good synergistic antiseptic effect and microbial tolerance, which is better than adding a single preservative. When the ratio of the two is 1:1.3, it has the best synergistic antiseptic effect.

Embodiment 8~15

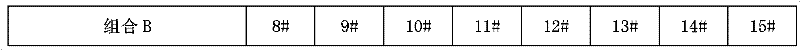

[0063]

[0064]

[0065] Add two kinds of preservatives of different concentration ratio in present embodiment 8~15, add 10 6 coli, test the colony concentration at intervals of 1h, 2h, 3h, and 4h. The negative logarithm of the colony concentration was plotted against the time to calculate the D value.

[0066] It can be seen from the calculated D value that when adding a preservative with a total concentration of 40ppm in the above examples, 1,2-benzisothiazolin-3-one and 2-methylisothiazolin-3-one complex When the ratio is 1:3, 3:5, 1:1, 5:3, 3:1, it has good synergistic antiseptic effect and microbial tolerance, which is better than adding a single preservative. When the concentration ratio of the two is 1:1, it has the best synergistic antiseptic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com