Combined static pile press

A technology of static pile driver and placing machine, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as affecting construction efficiency, increasing equipment investment, and troublesome equipment replacement, so as to improve construction efficiency and reduce equipment costs. The effect of investment, rational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is further described below in conjunction with embodiment and accompanying drawing.

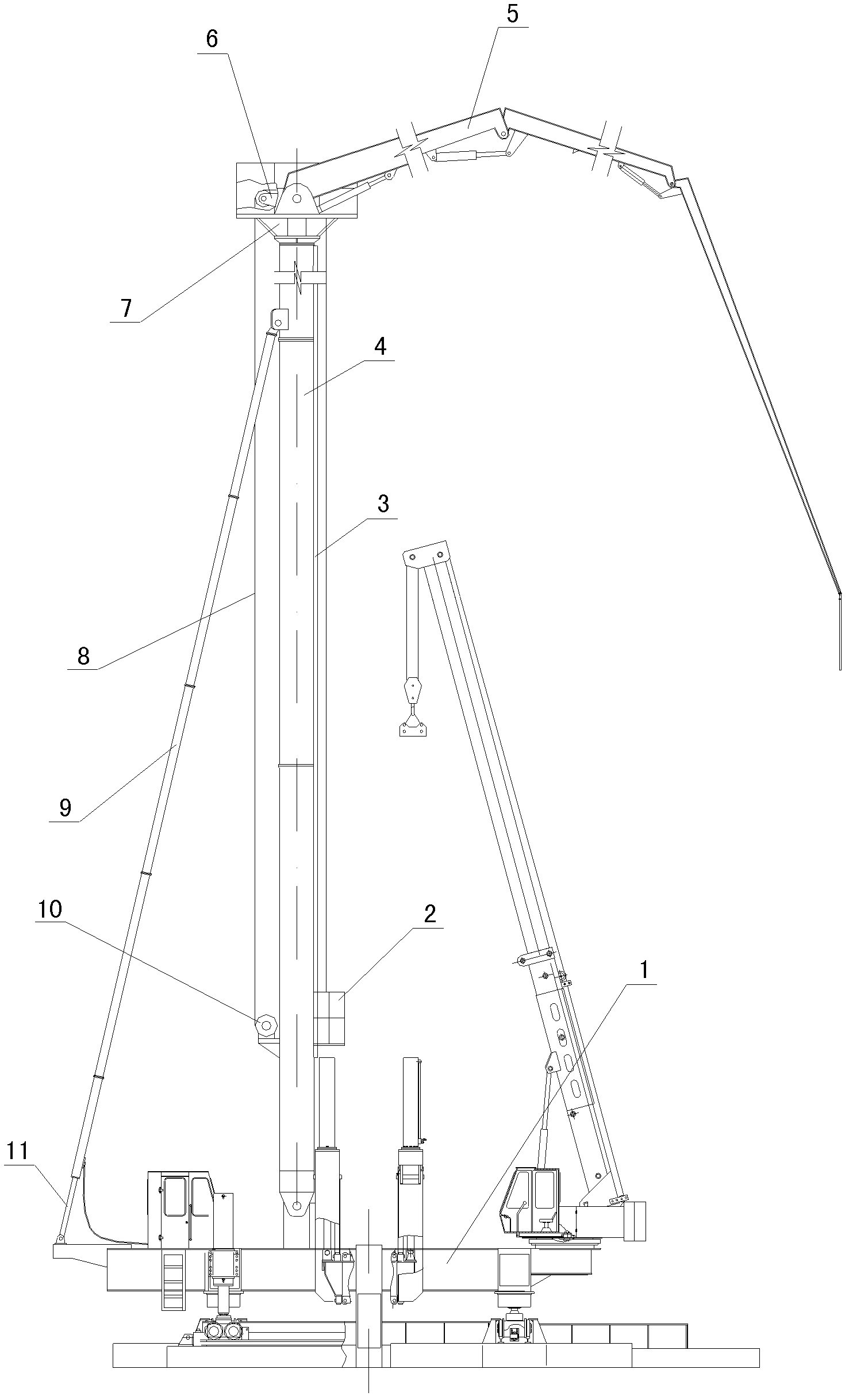

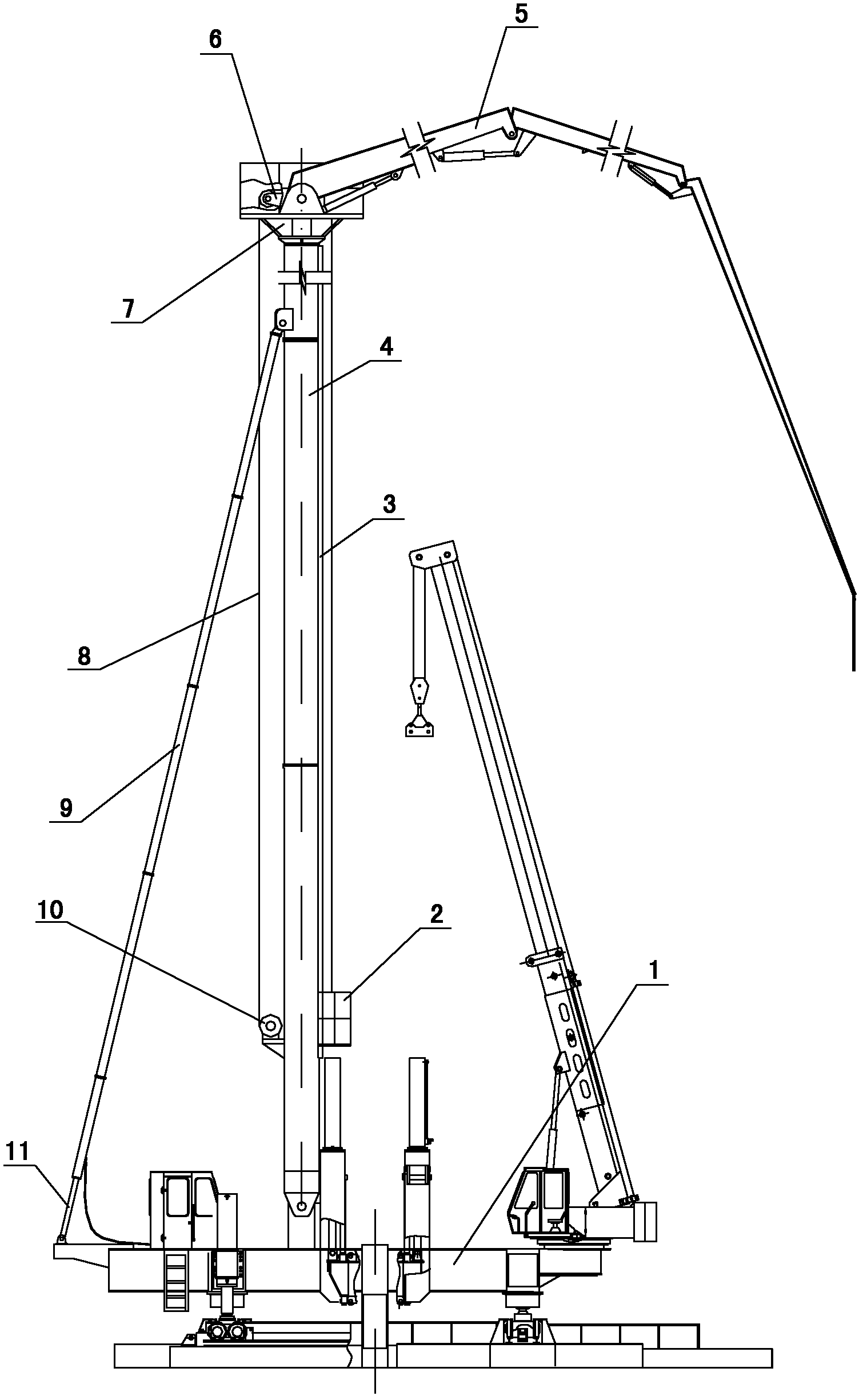

[0009] see attached image

[0010] The combined static pile driver provided by the present invention has a static pile driver 1, a mast 4 is hinged on the workbench of the static pile driver 1, and a diagonal support arm 9 is respectively hinged on both sides of the mast 4 (rear The oblique support arm on the side is blocked by the front side), and the lower end of each oblique support arm 9 is connected with the piston rod of the oil cylinder 11 hinged on the workbench. Platform 7, the concrete distributing machine 5 is installed on the slewing bearing platform 7. The oil cylinder and the hydraulic system on the slewing bearing platform are supplied with oil by the hydraulic pump station of the static pile driver. In addition, the structures of the slewing platform 7 and the concrete placing machine 5 are the same as those of the prior art. Concrete placing ma...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap