Four-degree-of-freedom connecting rod working mechanism containing composite hinges

A technology of working mechanism and degrees of freedom, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of low carrying capacity, affecting the working efficiency of mechanical equipment, small working space, etc., to achieve high carrying capacity, simplified analysis and size. Design, the effect of large workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

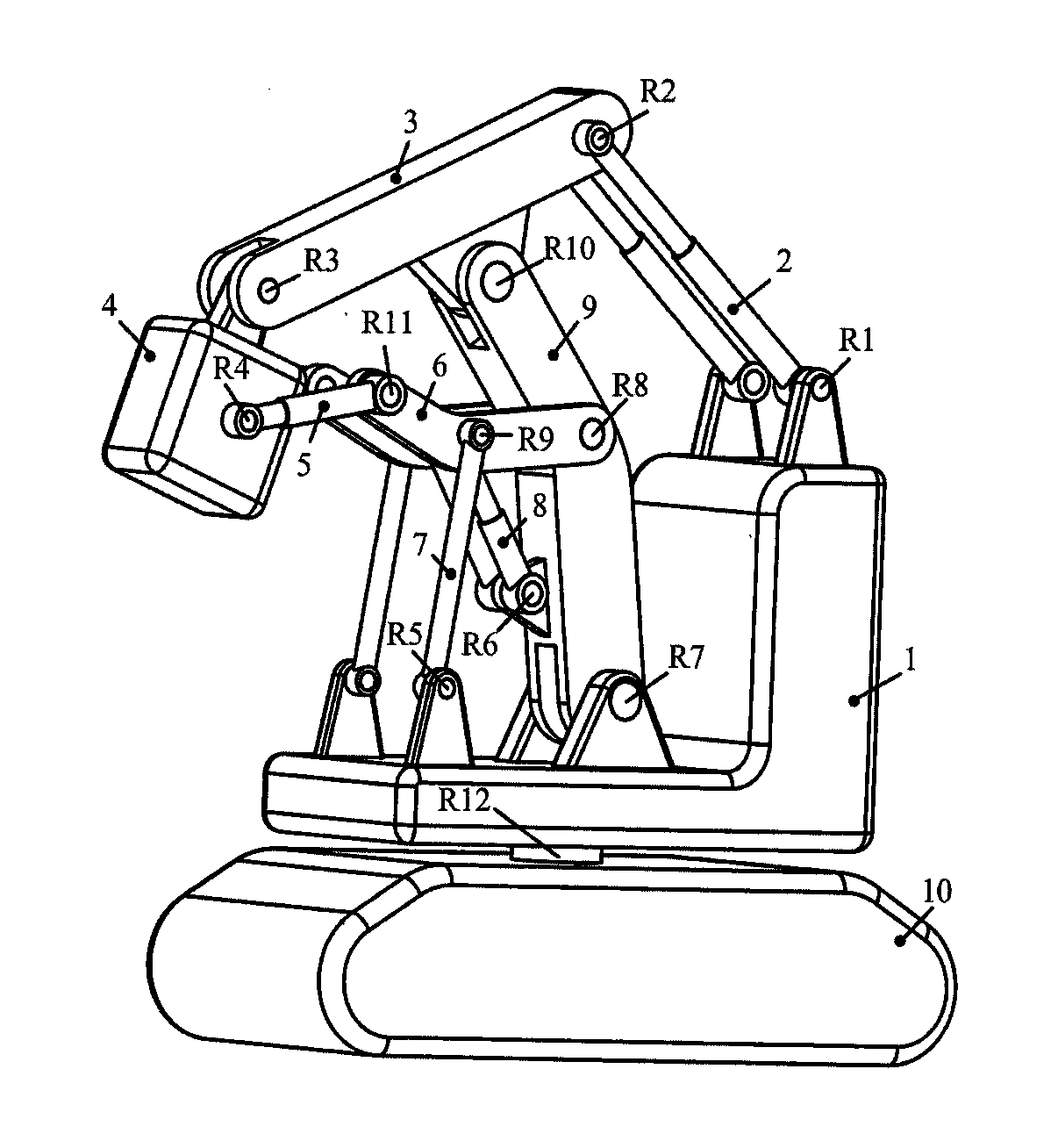

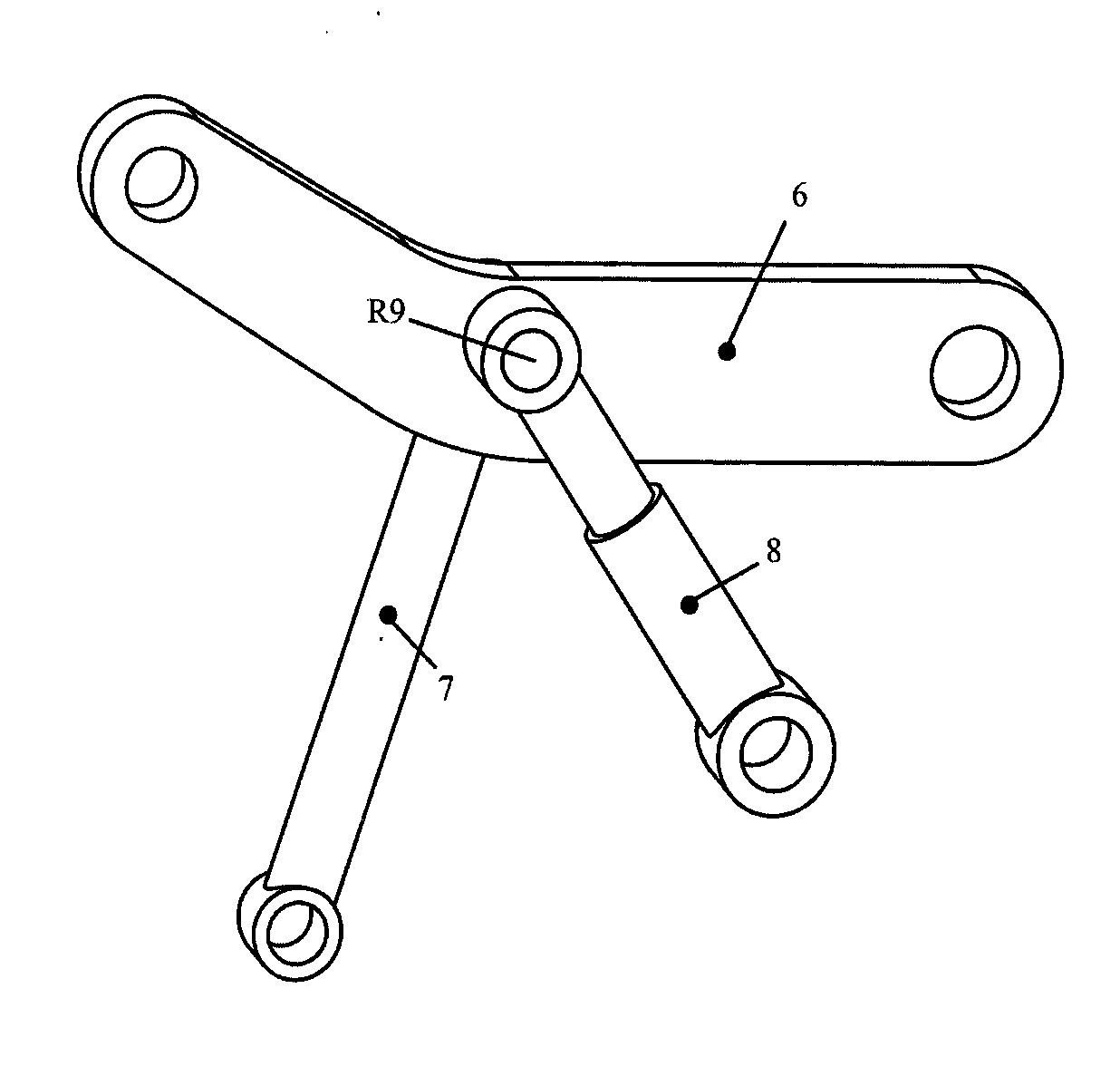

[0017] exist figure 1 In the three-dimensional schematic diagram of Embodiment 1 of a four-degree-of-freedom linkage working mechanism with compound hinges shown, the base 1 is connected to the crawler device 10 through a slewing device, and three pairs of parallel symmetrical bases are arranged on the base, among which The pair of bases in between are connected to the bottom end of the boom 9 through the hinge R7, the top of the boom is connected to the middle part of the forearm 3 through the hinge R10, and one end of the forearm is connected to a part of the end effector 4 through the hinge R3; The other end of the forearm is connected to the piston rod ends of a pair of forearm oil cylinders 2 through a hinge R2, and the cylinder liner end of the forearm oil cylinder is connected to a pair of bases at one end of the base through a hinge R1; The base is connected to one end of a pair of pull rods 7 through a hinge R5, and the pair of pull rods and the piston rod ends of a ...

Embodiment 2

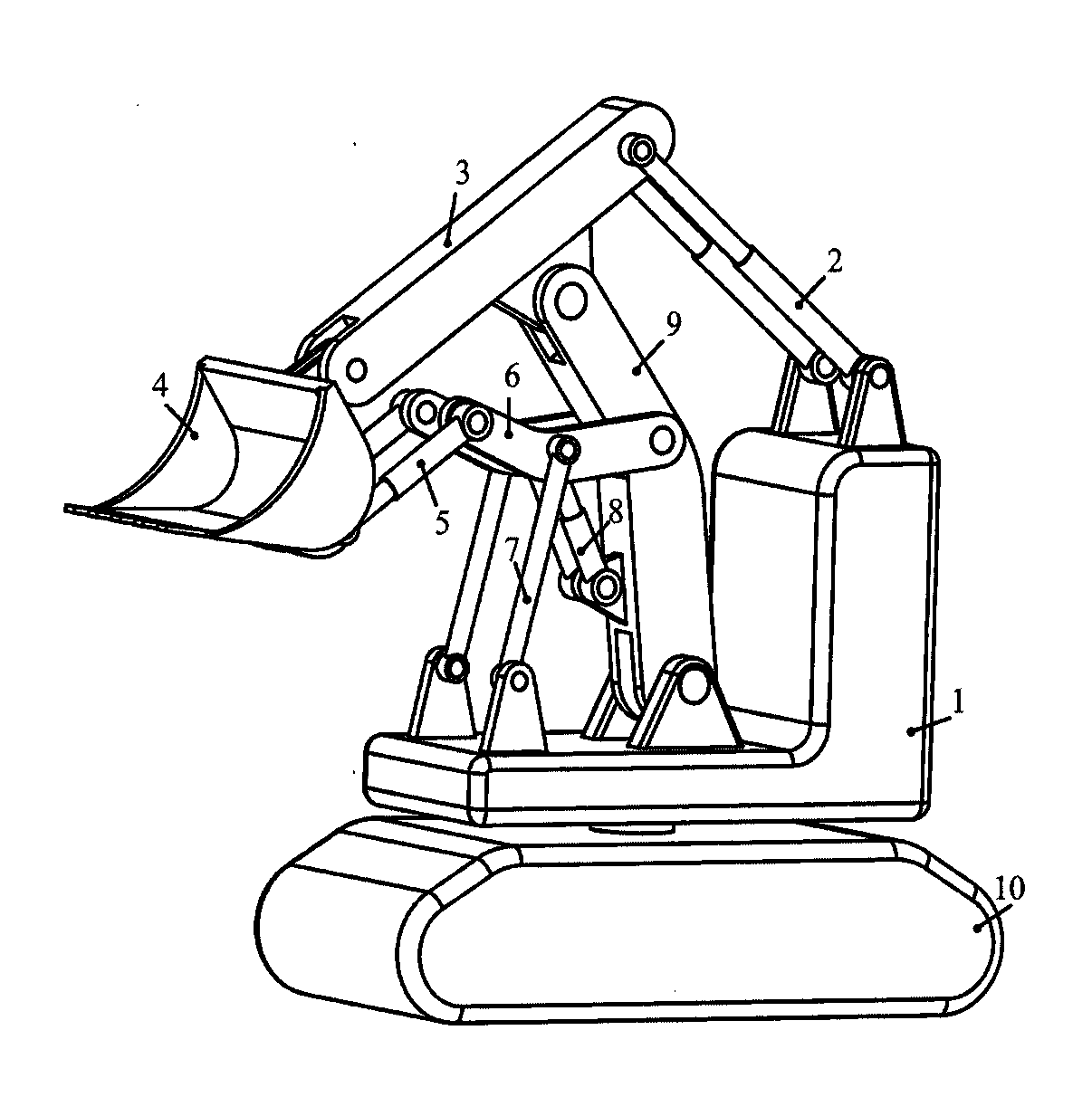

[0021] exist Figure 5 In the three-dimensional schematic diagram of Embodiment 2 of a four-degree-of-freedom connecting rod working mechanism containing compound hinges, the ends of the cylinder liners of a pair of end effector cylinders 5 and one end of a pair of rockers 6 pass through the hinge R9 respectively. Connected to both sides of the middle part of the boom 9 to form two symmetrically distributed compound hinges, the other end of the rocker is connected to the end of the pull rod through the hinge R11, and the connection relationship of other components is the same as figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com