Continuously switchable four-way rotary valve

A rotary valve, rotary valve core technology, applied in multi-port valves, valve details, valve devices and other directions, can solve the problems of short service life, frequent valve opening and closing, complex control, etc., to achieve long service life, good sealing, Install simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

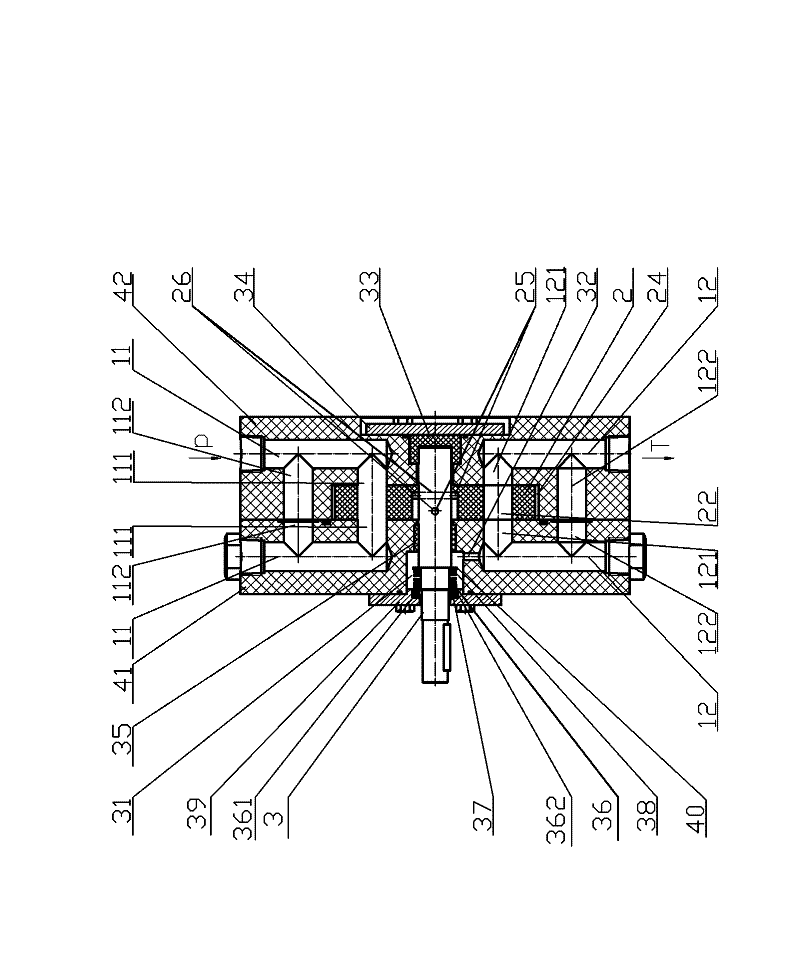

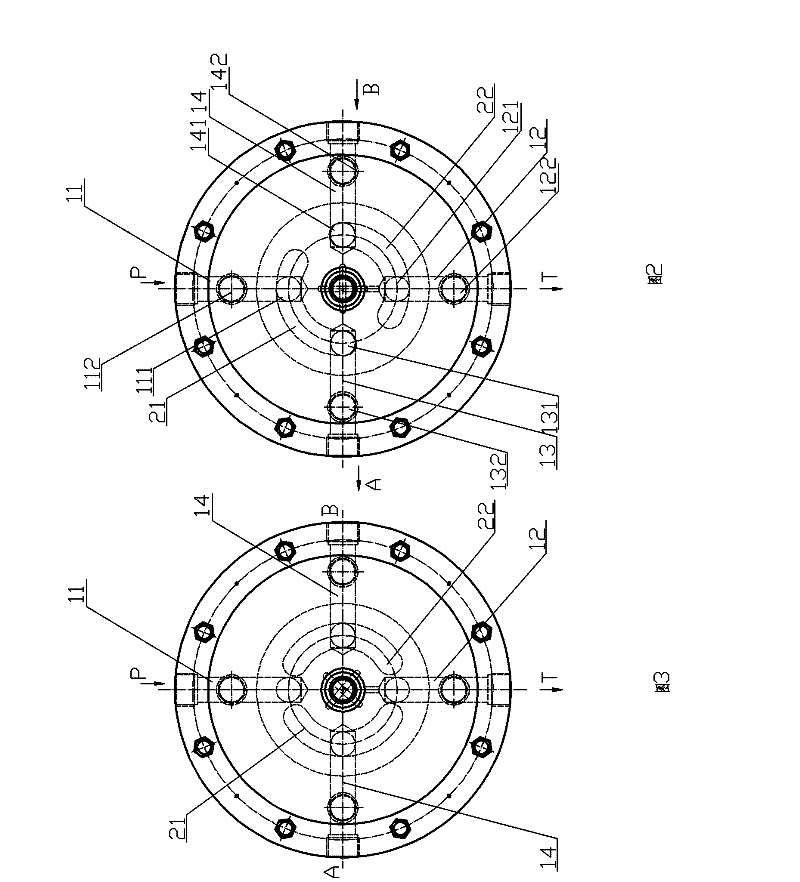

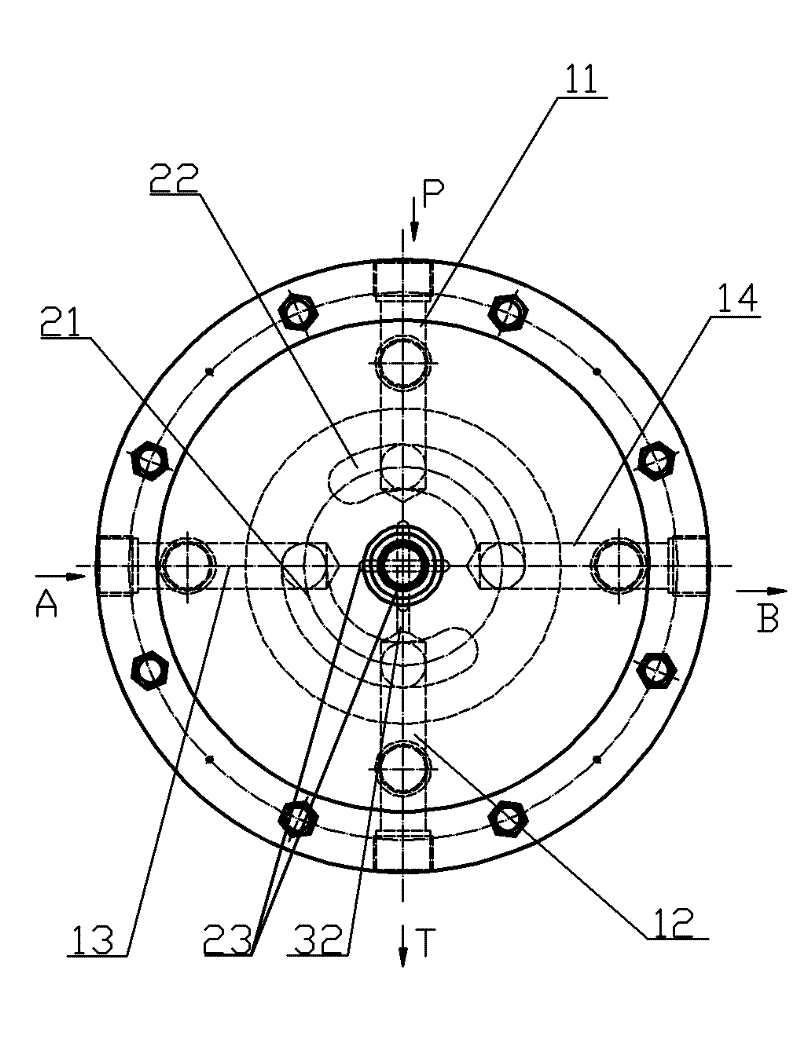

[0041] Embodiment 1, with reference to Figure 1-4 .

[0042] The four-way rotary valve includes a valve body and a rotary valve core 2 .

[0043] The valve body is provided with a first fluid passage 11, a second fluid passage 12, a third fluid passage 13, and a fourth fluid passage 14 in the axial direction and front and back of the rotary valve core, and the communication between the first fluid passage 11 and the outside world The port P is dedicated to water intake, the communication port T between the second fluid channel 12 and the outside world is dedicated to water outlet, the communication port A between the third fluid channel 13 and the outside world is used for water outlet and water intake, and the communication port between the fourth fluid channel 14 and the outside world B is used for water outlet and water intake, and the order along the circumference of the rotary valve core 2 is the first fluid channel 11, the third fluid channel 12, the second fluid chann...

Embodiment 2

[0056] Embodiment 2, with reference to attached Figure 5-8 .

[0057] The four-way rotary valve includes a valve body and a rotary valve core 2, and the rotary valve core 2 is connected to a stepped shaft 3 to be driven by a motor.

[0058] Along the axial direction of the stepped shaft, the four-way rotary valve is provided with a plurality of valve body units, and the valve body units are divided into end units and the same intermediate unit, with the end where the stepped shaft passes through the valve body as the top , the end unit is an upper unit 41 and a bottom unit 42. In this embodiment, there are 3 intermediate units whose labels are respectively 43, 44, and 45. The valve body is connected by bolts by the valve body unit. As a result, a valve core 2 is provided between the valve bodies of adjacent units, and the two adjacent valve body units are sealed with seals outside the valve core 2. With this structure, each intermediate unit can be made the same to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com