Double reinforced plastic composite water pipe, device and method for manufacturing water pipe, and special-shaped strip for manufacturing water pipe

A technology for reinforced plastics and water pipes, applied in the field of composite water pipes, can solve the problems of inability to manufacture large-diameter pipes, inability to provide bearing internal pressure, inability to enhance axial strength, etc., and to achieve the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

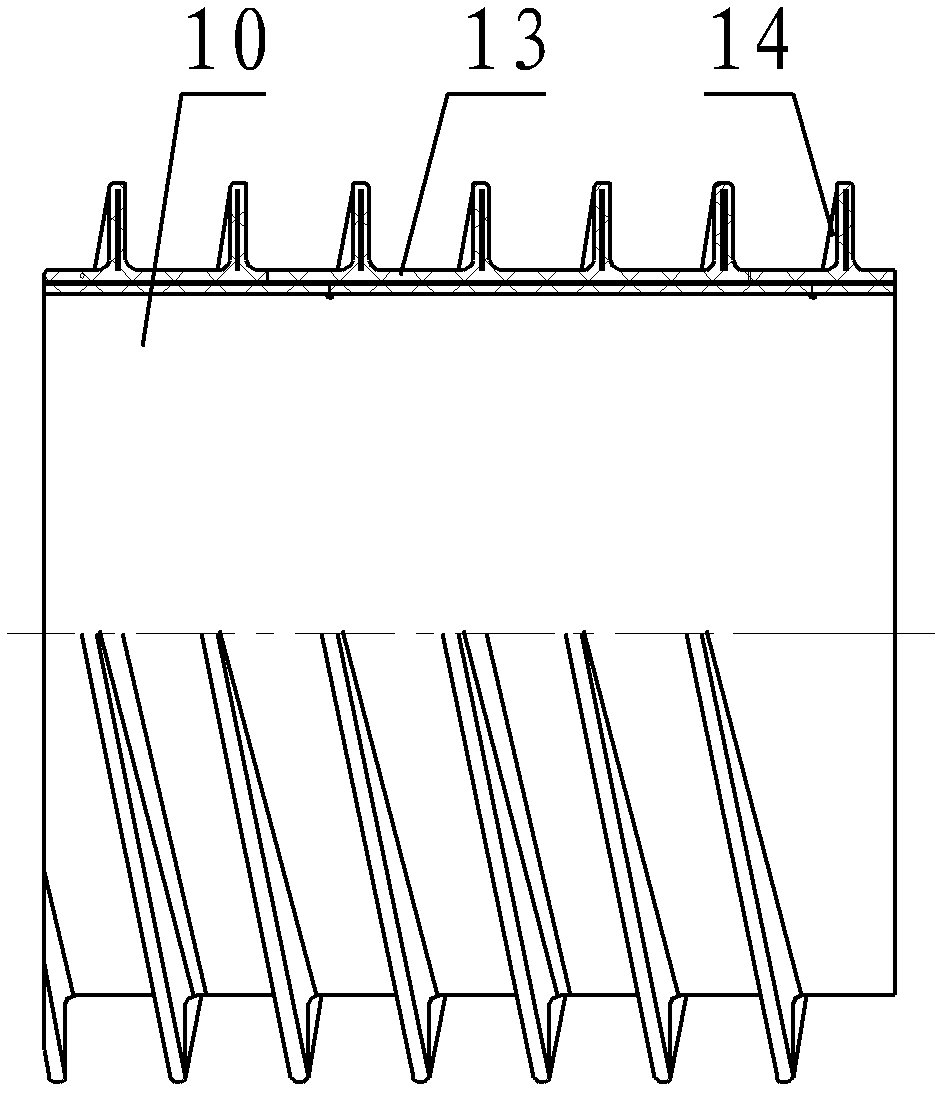

[0030] figure 1 The shown water pipe 10 includes a plastic pipe wall 13 with a steel mesh or a metal orifice plate and a vertical reinforcing rib 14 with a steel strip, the two are integrated, and are formed by winding and lap welding plastic composite special-shaped strips 11 .

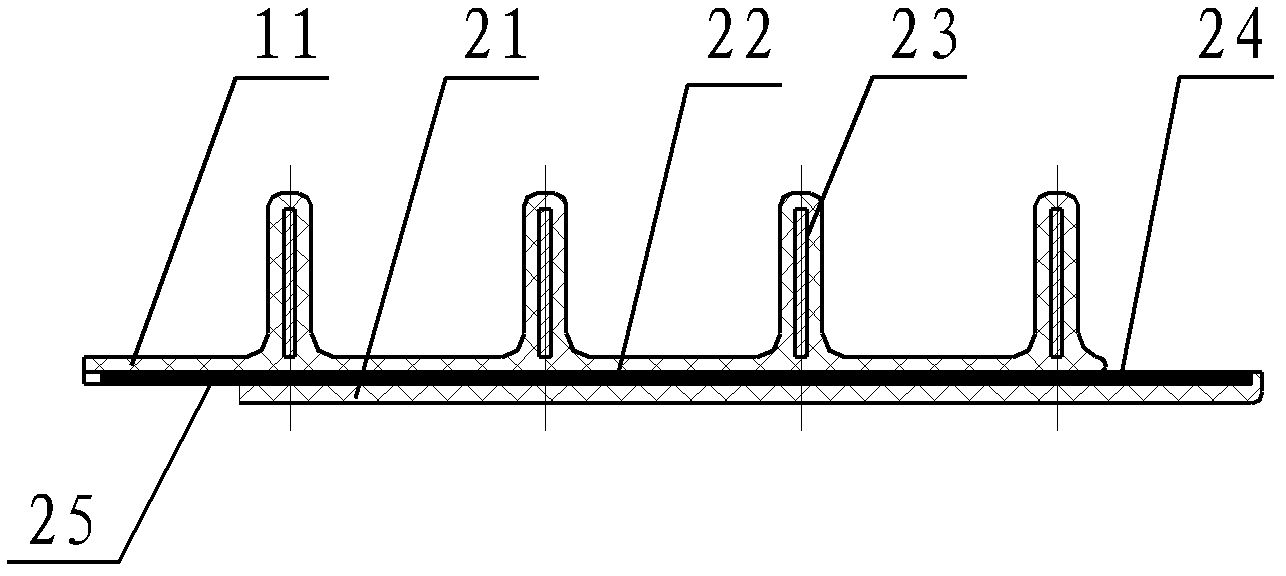

[0031] figure 2 The plastic composite special-shaped strip 11 forming the water pipe shown in the figure includes a plastic lower strip base 21 and an upper strip base 23 with an integrated steel belt reinforced vertical rib part, and a steel mesh or metal hole plate 22 is embedded in the Between the plastic lower strip base layer 21 and the upper strip base layer 23, a complete strip base layer is formed by melting plastics and both composites, wherein the width of the steel mesh or the metal orifice plate 22 is the width of the entire strip material 11, and the belt The width of the upper strip base layer 23 with the vertical reinforcing rib portion of the material 11 is smaller than the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com