D-shaped spiral corrugated pipe and manufacturing method

A technology of spiral corrugated pipe and manufacturing method, which is applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., which can solve the problems of low support strength, reduced strength of corrugated pipes, and reduced strength of inner polyethylene, so as to improve the support Strength and pressure bearing capacity, large bearing capacity, and the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

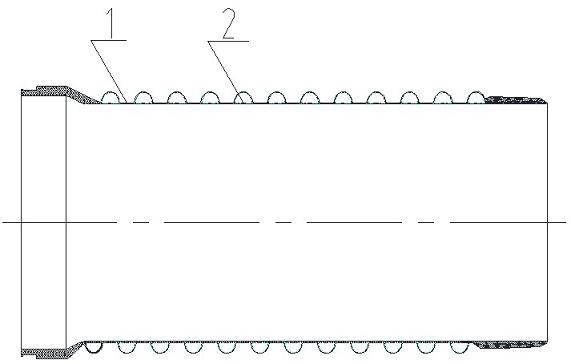

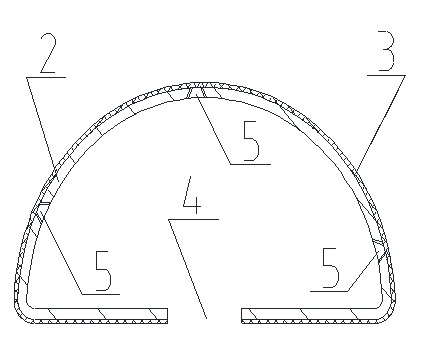

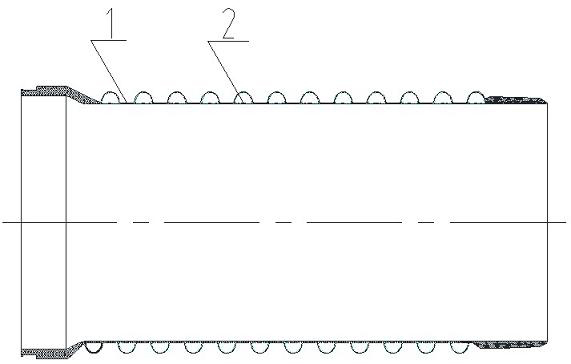

[0010] Embodiment 1: with reference to attached Figure 1-2 . A D-shaped spiral corrugated pipe, which includes an inner tube 1, a metal tube 2 wound on the body of the inner tube 1 has a D-shaped cross section, and the bottom surface of the D-shaped metal tube is combined with the body of the inner tube 1, and the D-shaped metal tube The pipe surface of the pipe 2 is covered with a plastic layer 3 . The bottom surface of the D-shaped metal tube 2 has an opening structure 4 . The bottom surface of the D-shaped metal tube 2 has an opening width smaller than 20 mm. A plurality of through holes 5 are opened on the semicircular surface of the D-shaped metal tube 2 and the through holes 5 are in the shape of an inner trumpet. The opening refers to the opening 4 in the length direction of the D-shaped metal pipe. The D-shaped metal pipe 2 is made of steel strip.

Embodiment 2

[0011] Example 2: On the basis of Example 1, a method for manufacturing a D-shaped spiral corrugated pipe, using a metal pipe making machine to make a steel strip into a semicircular D-shaped metal pipe with an opening plane at the bottom, and then using the applicant In the production line of the large-diameter polyolefin winding growth pipe produced by the corrugated pipe inner pipe 1, while making the corrugated pipe inner pipe, the semicircular D-shaped pipe is wound on the corrugated pipe, and the plastic on the wall of the corrugated pipe is embedded in the semicircular D-shaped pipe. In the opening of the pipe, the large-diameter polyolefin winding growth pipe production line manufactured by the applicant is finally used to compound the molten plastic on the semicircular D-shaped pipe. The semicircular surface of the D-shaped metal pipe 2 is pressed into a concave-convex surface by a mold, and an inner trumpet-shaped through hole 5 is opened in the center of the groove s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com