Method for directly starting steam-driven feed water pump of large-sized thermal power plant

A steam-driven feedwater pump and thermal power plant technology, applied in the direction of water supply control, steam generation, preheating, etc., can solve problems such as poor economy, and achieve the effect of saving operating costs and saving initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

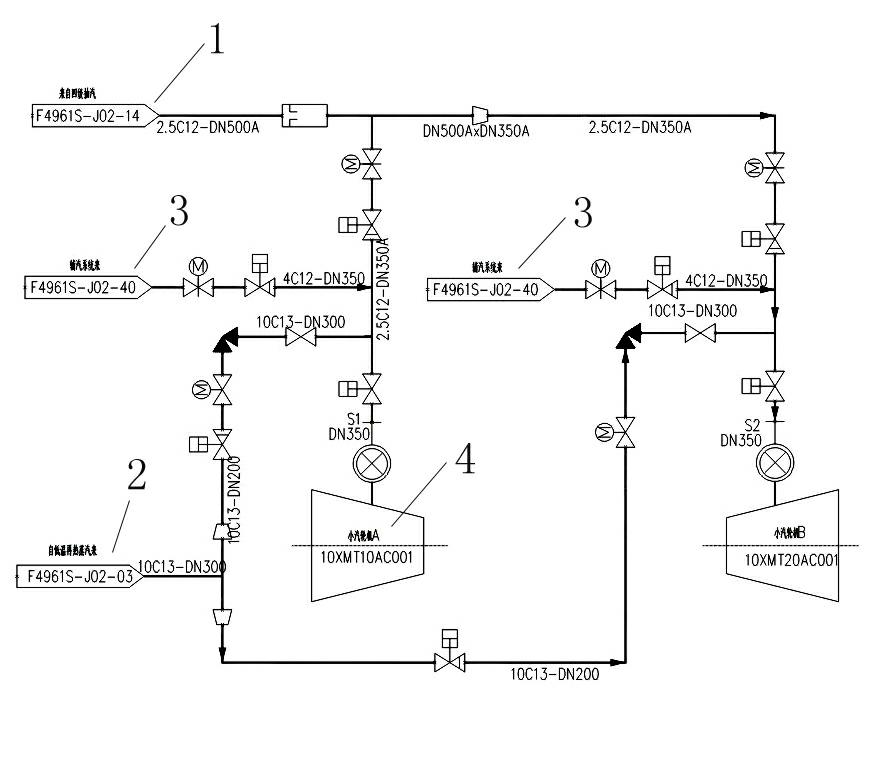

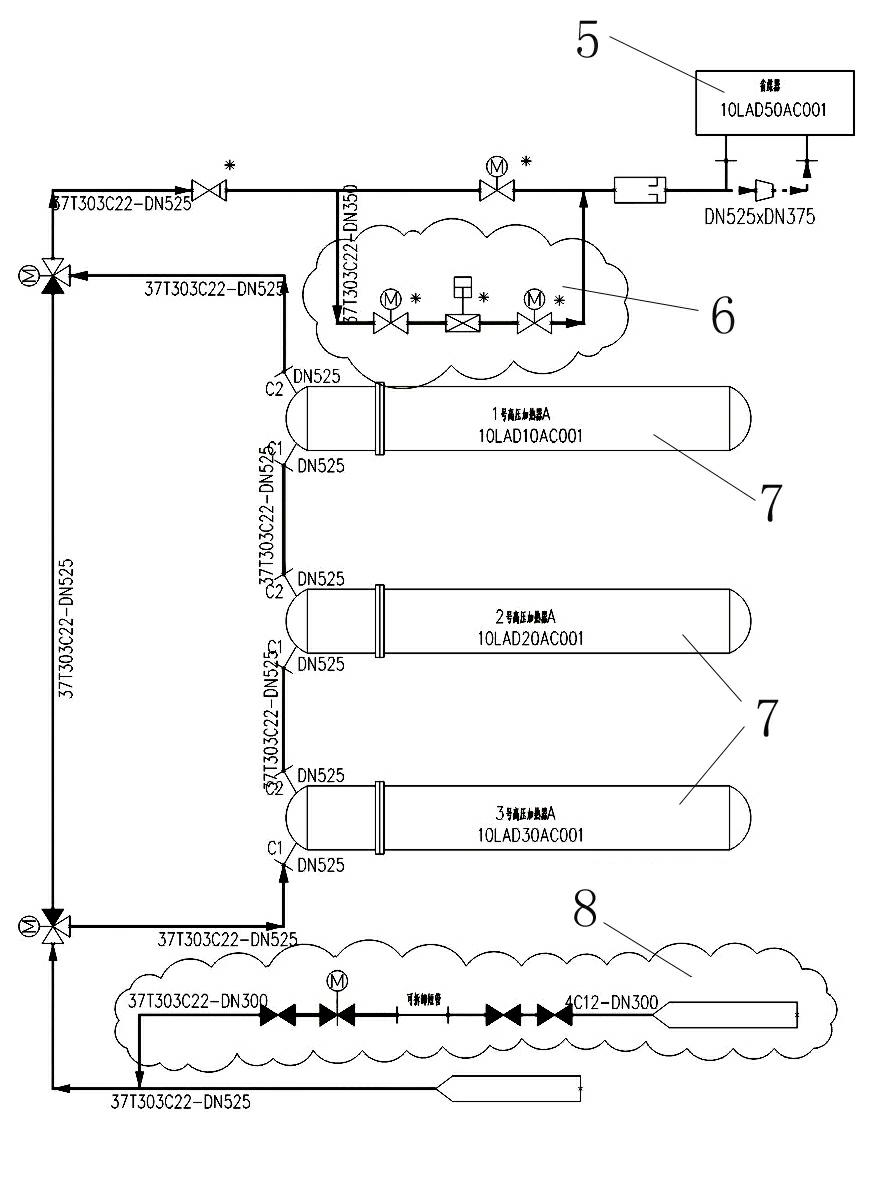

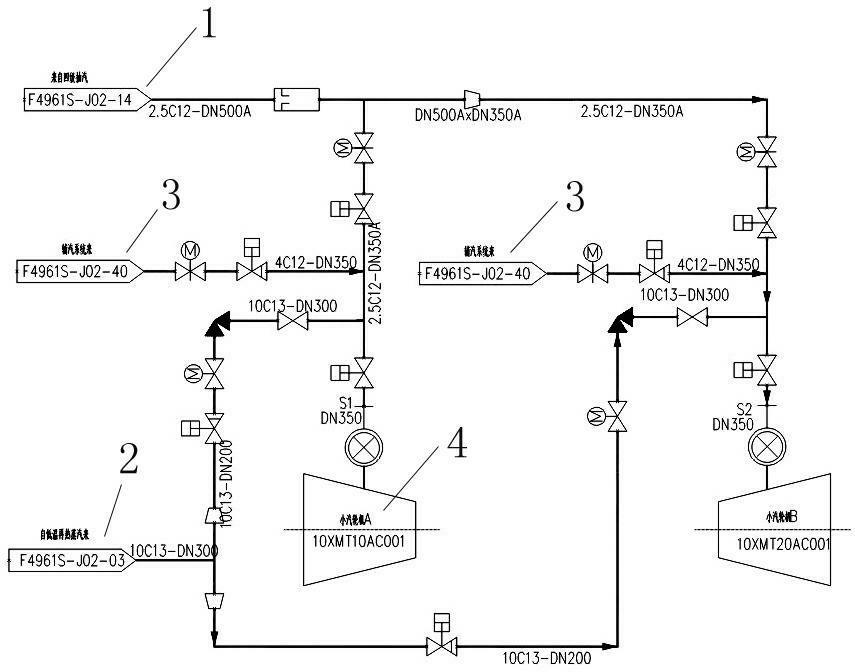

[0019] Feedwater pump turbines are generally only designed with two inlet steam sources, which are supplied by four-stage extraction steam during normal operation, and are supplied by cold section steam or main steam when the unit is started or under low load. Therefore, since the two steam sources cannot be supplied during the starting process, the steam-driven feedwater pump cannot be used as the starting pump. If an auxiliary steam source is added, at startup, the auxiliary steam is used to flush the feed pump turbine, and the steam-driven feed pump completes the boiler water supply process. When the cold section steam (or main steam) parameter reaches the feed pump turbine inlet steam parameter When required, the steam inlet mode of the small engine is gradually switched from auxiliary steam to cold section steam (or main steam) to realize the start-up function of the steam-driven feedwater pump.

[0020] Use the steam-driven feedwater pump to start directly. In addition to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com